Technical Report Summary on the

Technical Report Summary on the

Tilden Property, Michigan, USA

S-K 1300 ReportCleveland-Cliffs Inc.

SLR Project No: 138.02467.00001

February 7, 2022

Effective Date: December 31, 2021

Technical Report Summary on the Tilden Property, Michigan, USA

SLR Project No: 138.02467.00001

Prepared by

SLR International Corporation

1658 Cole Blvd, Suite 100

Lakewood, CO 80401

for

Cleveland-Cliffs Inc.

200 Public Square, Suite 3300

Cleveland, OH 44114-2544

USA

Effective Date – December 31, 2021

Signature Date - February 7, 2022

Distribution: 1 copy – Cleveland-Cliffs Inc.

1 copy – SLR International Corporation

CONTENTS

| | | | | |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

3.3 Encumbrances | 28 |

3.4 Royalties | 28 |

3.5 Other Significant Factors and Risks | 28 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

6.4 Deposit Types | 43 |

| |

| |

7.2 Geological Mapping | 50 |

7.3 Hydrogeology and Geotechnical Data | 50 |

| |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 i

| | | | | |

| |

| |

| 58 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

11.4 Resource Assays | 77 |

11.5 Compositing and Capping | 77 |

11.6 Trend Analysis | 81 |

11.7 Block Model | 84 |

11.8 Estimation Methodology | 84 |

11.9 Cut-off Grade | 86 |

11.10 Classification | 86 |

11.11 Model Validation | 89 |

11.12 Model Reconciliation | 94 |

11.13 Mineral Resource Statement | 95 |

| |

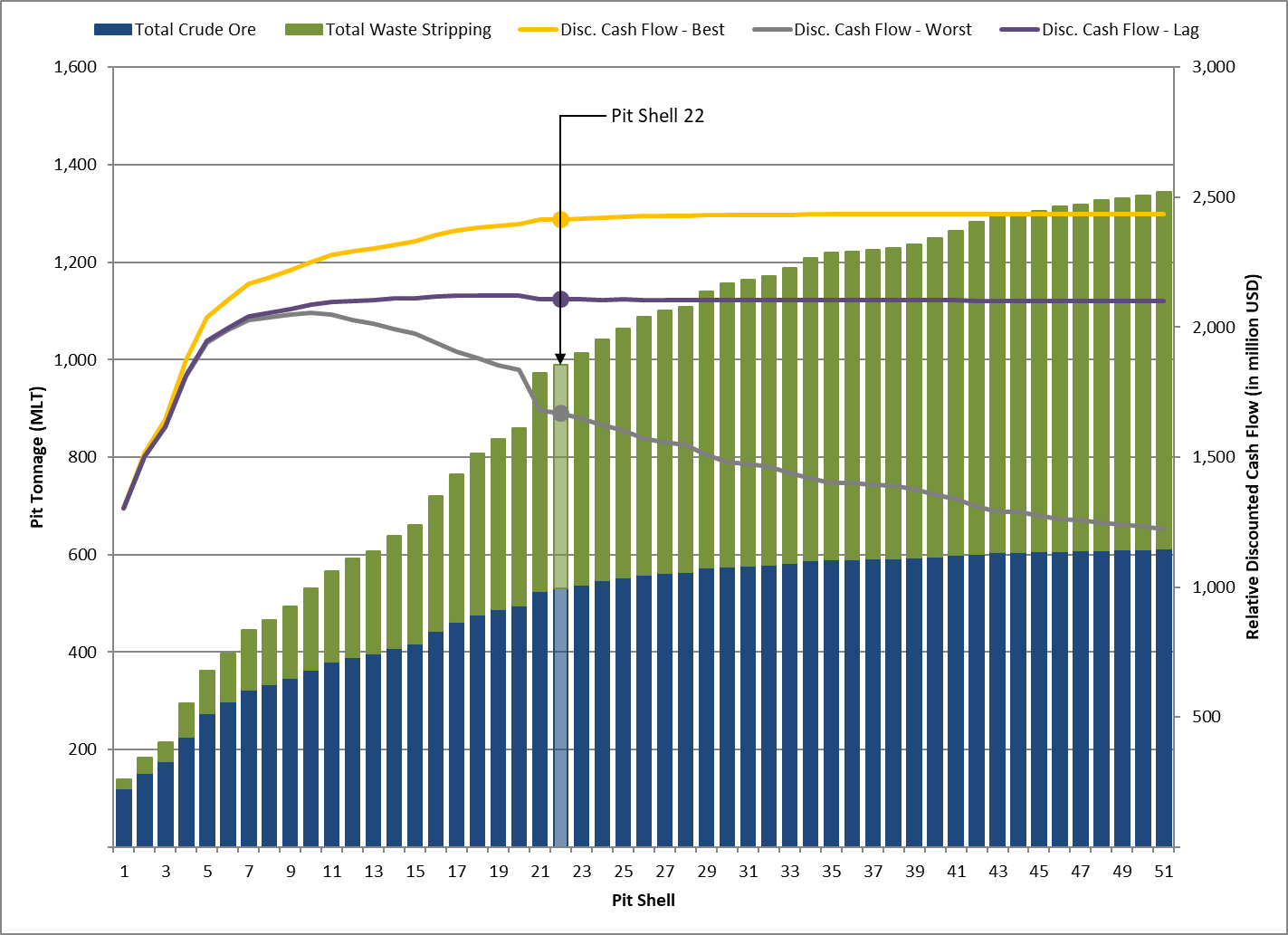

| 97 |

| |

| |

12.4 Mineral Reserve Cut-off Grade | 106 |

12.5 Mine Design | 106 |

| |

| |

| |

13.3 Open Pit Design | 115 |

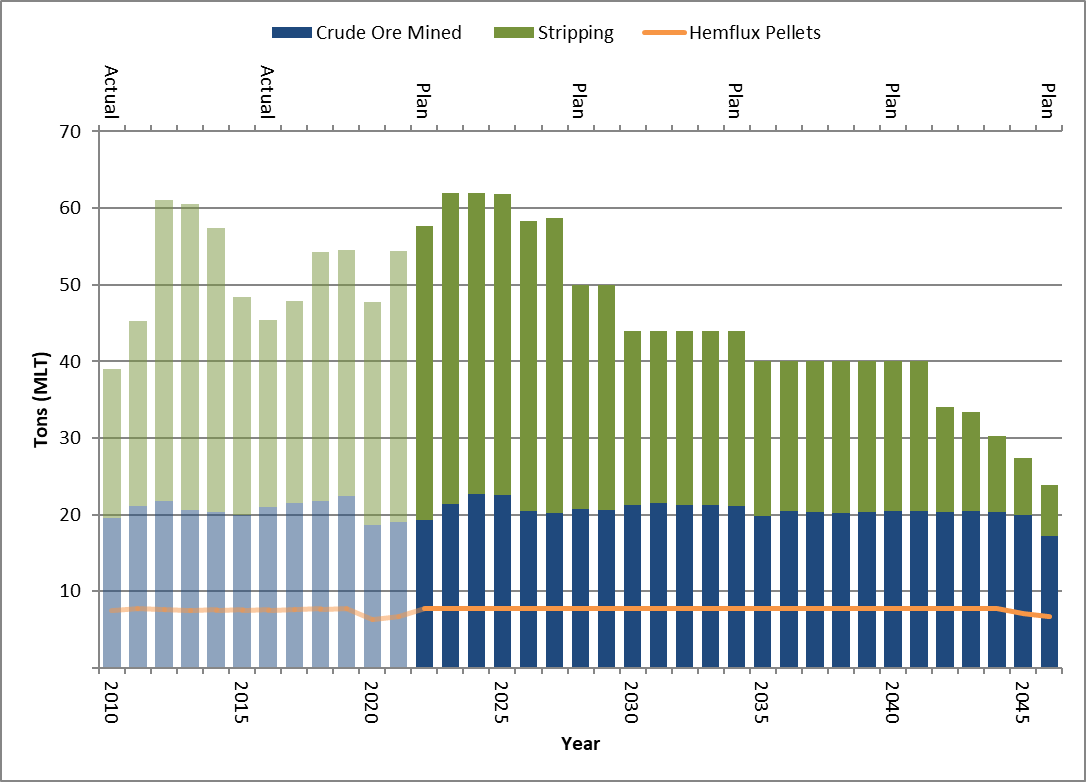

13.4 Production Schedule | 122 |

13.5 Overburden and Waste Rock Stockpiles | 124 |

13.6 Mining Fleet | 127 |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 ii

| | | | | |

13.7 Mine Manpower | 128 |

| |

| |

| |

14.3 Pelletizing Plant | 132 |

14.4 Major Equipment | 134 |

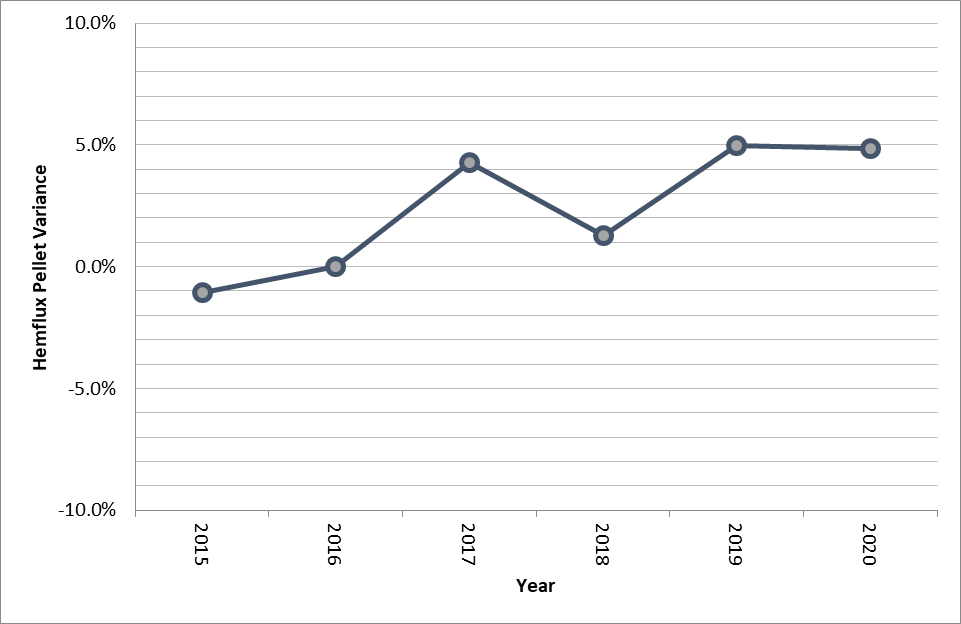

14.5 Plant Performance | 135 |

14.6 Pellet Quality | 136 |

14.7 Consumable Requirements | 136 |

14.8 Process Workforce | 139 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| 159 |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 iii

TABLES

| | | | | |

| |

| |

| |

| |

| |

| |

| 16 |

| |

| |

| |

| |

| |

Table 6-1: Geometallurgical Groupings at Tilden | 42 |

| |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 iv

| | | | | |

| |

| |

| |

| 73 |

Table 11-2: Tilden Mine Mineral Resource Database | 77 |

Table 11-3: Tilden Mine Composite Statistics | 78 |

Table 11-4: Tilden Variogram Models | 83 |

Table 11-5: Summary of Block Model Setup | 84 |

Table 11-6: Search Strategy | 85 |

Table 11-7: Whittle Pit Parameters | 86 |

Table 11-8: Classification Criteria | 87 |

Table 11-9: 2021 Model Reconciliation | 94 |

Table 11-10: Summary of Mineral Resources – December 31, 2021 | 95 |

| |

| |

| |

| |

| |

Table 12-6: Pit Optimization to Pit Design Comparison | 106 |

| |

Table 13-2: Summary of UCS and BTS Test Results | 112 |

Table 13-3: Summary of Direct Shear Test Results | 112 |

Table 13-4: Material Properties Used in Overall Slope Stability Analysis | 113 |

Table 13-5: Anisotropic Material Properties Used in the Weak Direction | 114 |

Table 13-6: Final Pit Design LOM Total - December 31, 2021 | 115 |

Table 13-7: LOM Production Schedule | 123 |

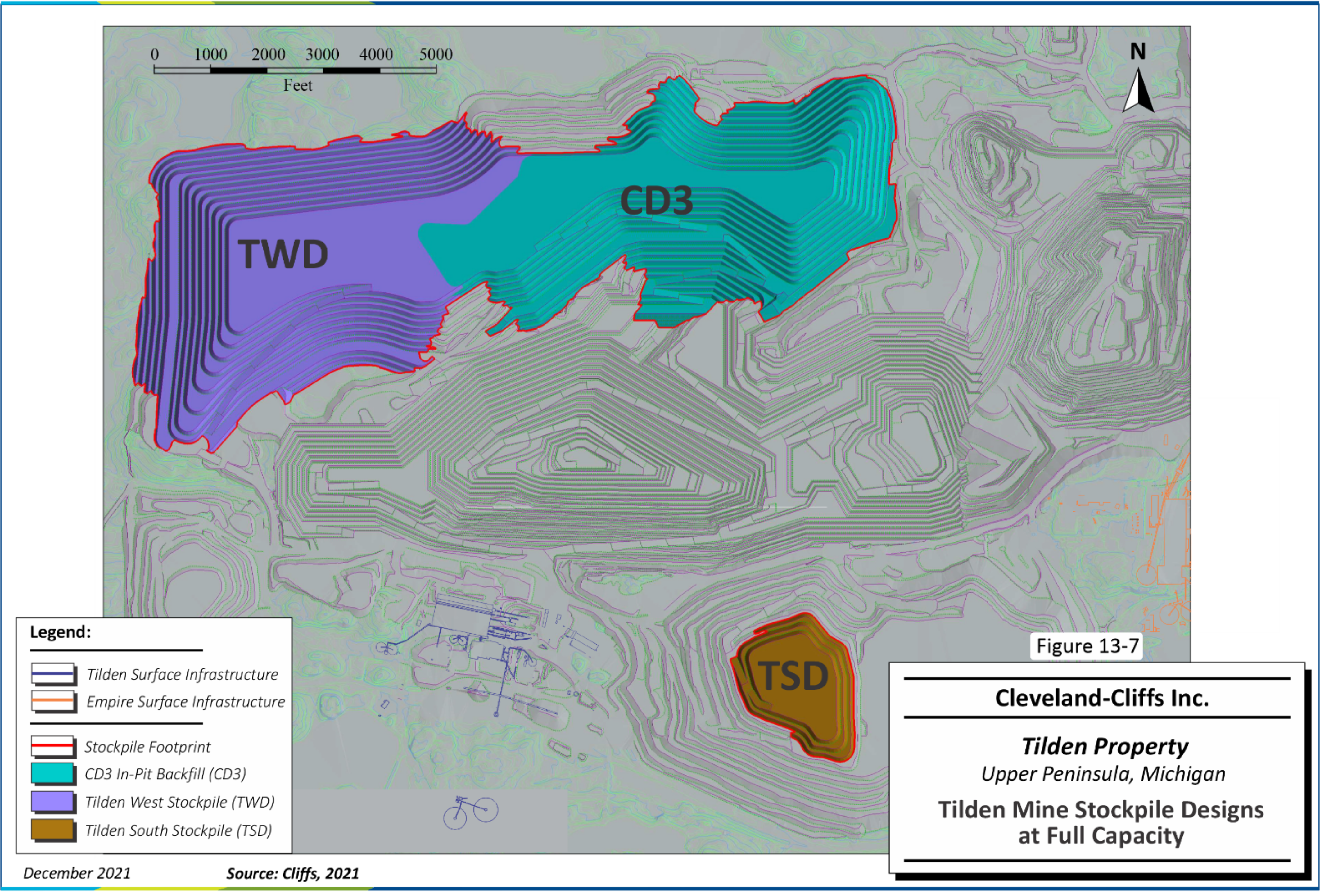

Table 13-8: Stockpile Parameters | 125 |

Table 13-9: Volumes and Capacities of Stockpile Designs | 125 |

Table 13-10: Major Mining Equipment | 127 |

Table 14-1: Major Processing Equipment | 134 |

Table 14-2: Tilden Concentrator Performance 2014 to 2020 | 135 |

Table 14-3: Hemflux Pellet Quality | 136 |

Table 14-4: Consumables | 138 |

| |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 v

FIGURES

| | | | | |

| |

| |

Figure 3-3: Surface Rights | 27 |

| |

| |

| |

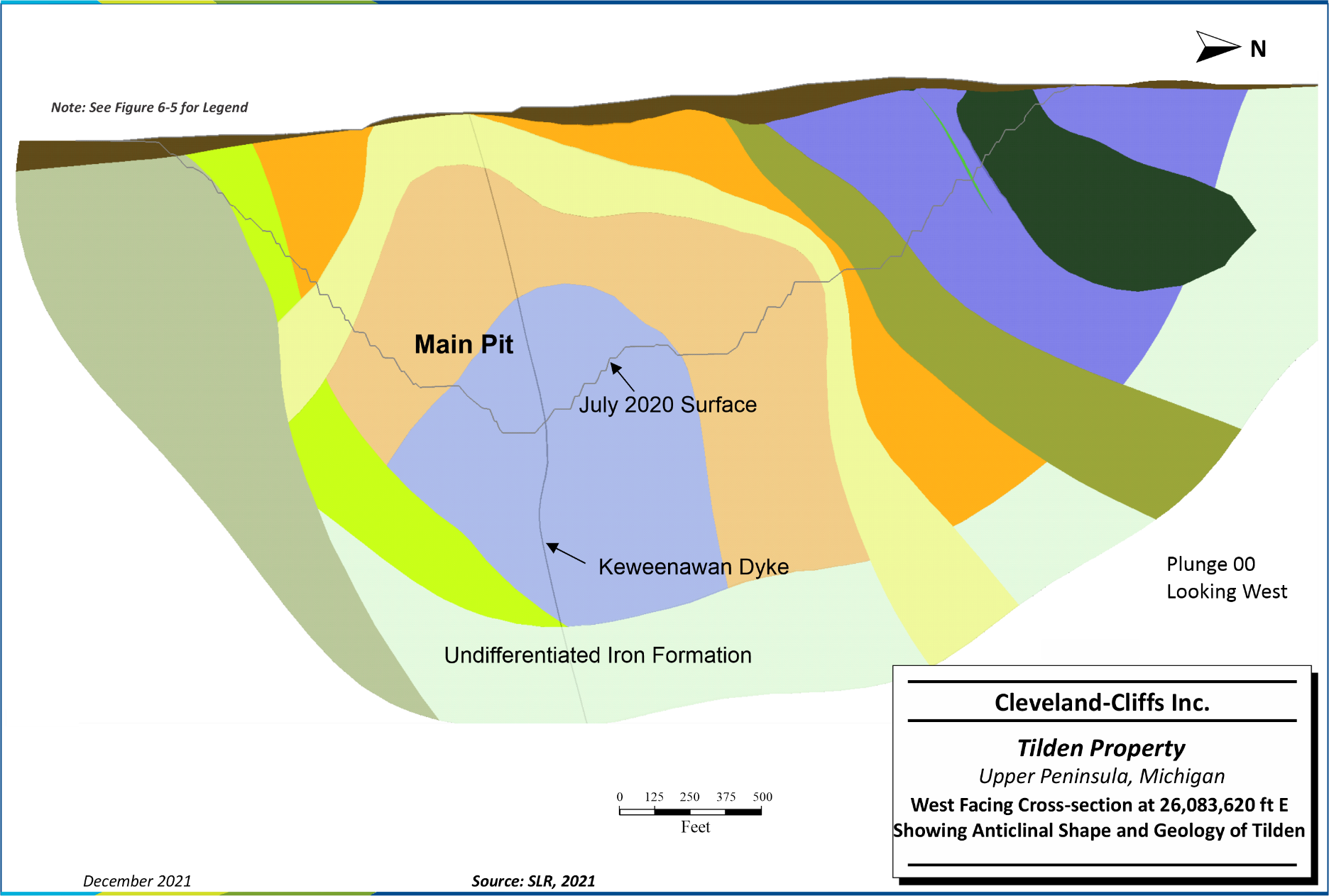

Figure 6-4: West-Facing Cross-section at 26,083,620 ft E Showing Anticlinal Shape and Geology of Tilden | 40 |

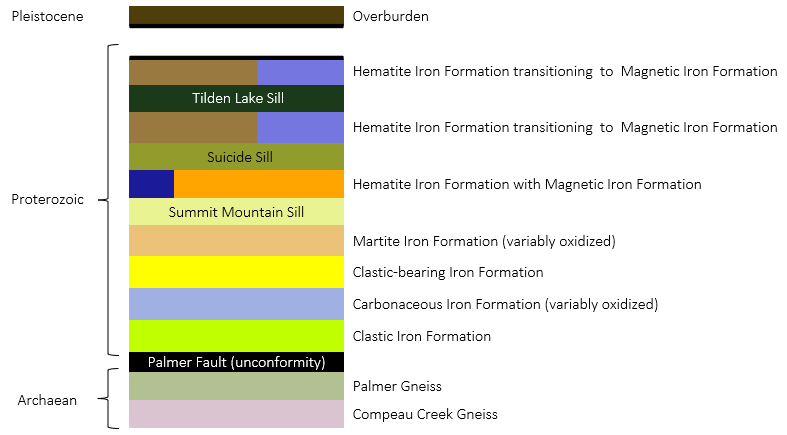

Figure 6-5: Basic Stratigraphic Section Local to Tilden | 41 |

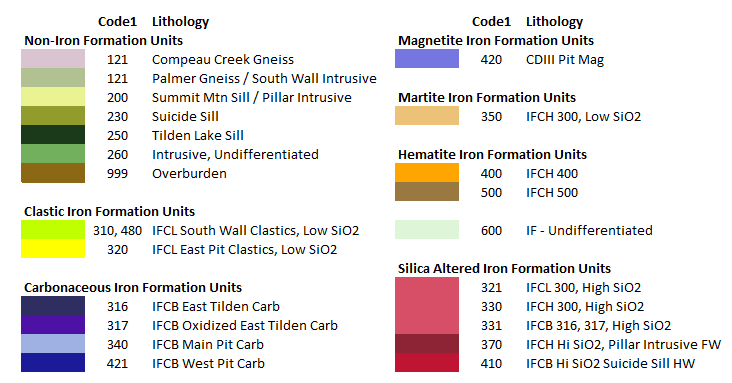

Figure 6-6: Selected Geometallurgical (code1) Groupings and Sub-groupings at Tilden | 43 |

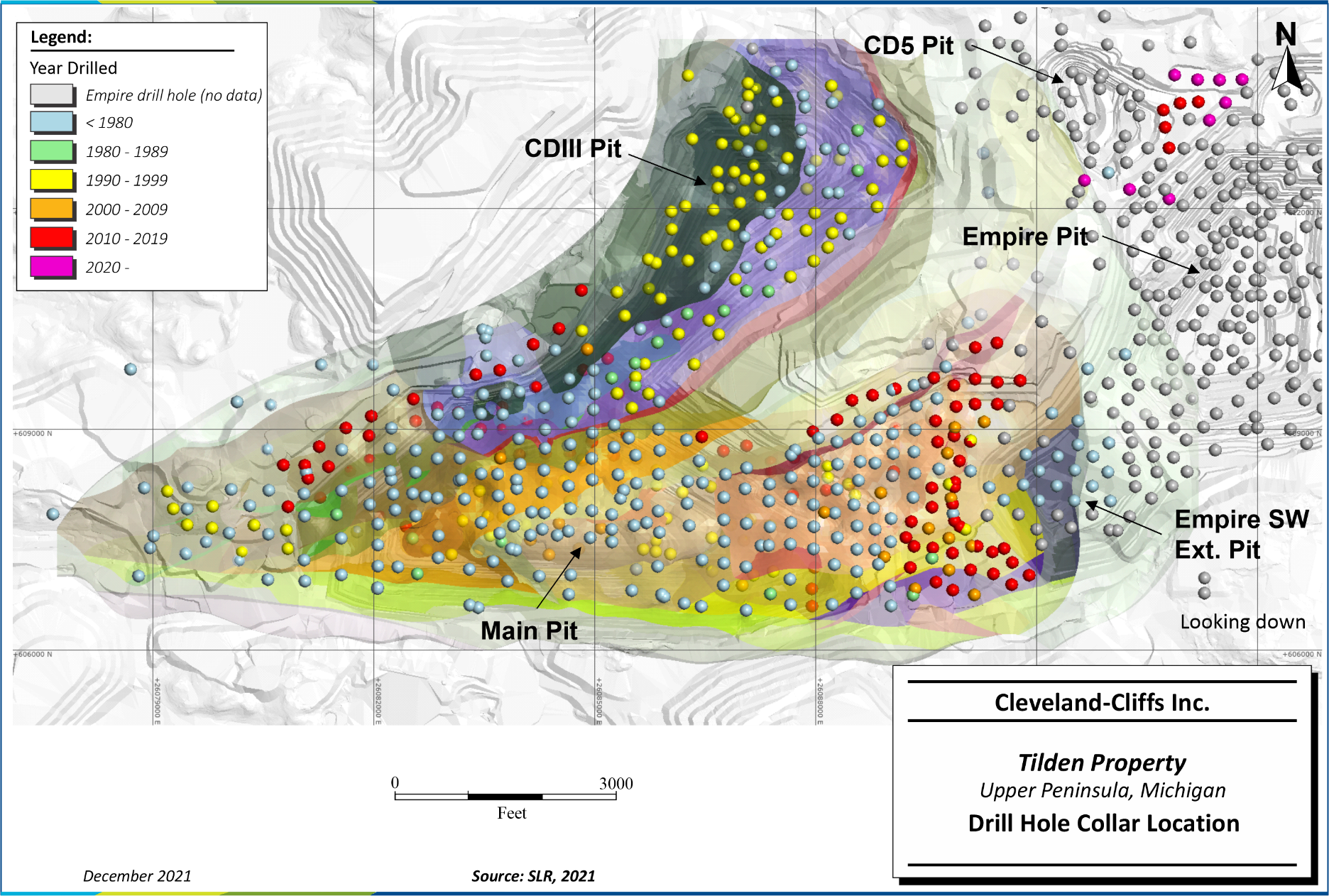

Figure 7-1: Drill Hole Collar Location | 47 |

| |

| |

| |

| |

| |

| |

| |

| |

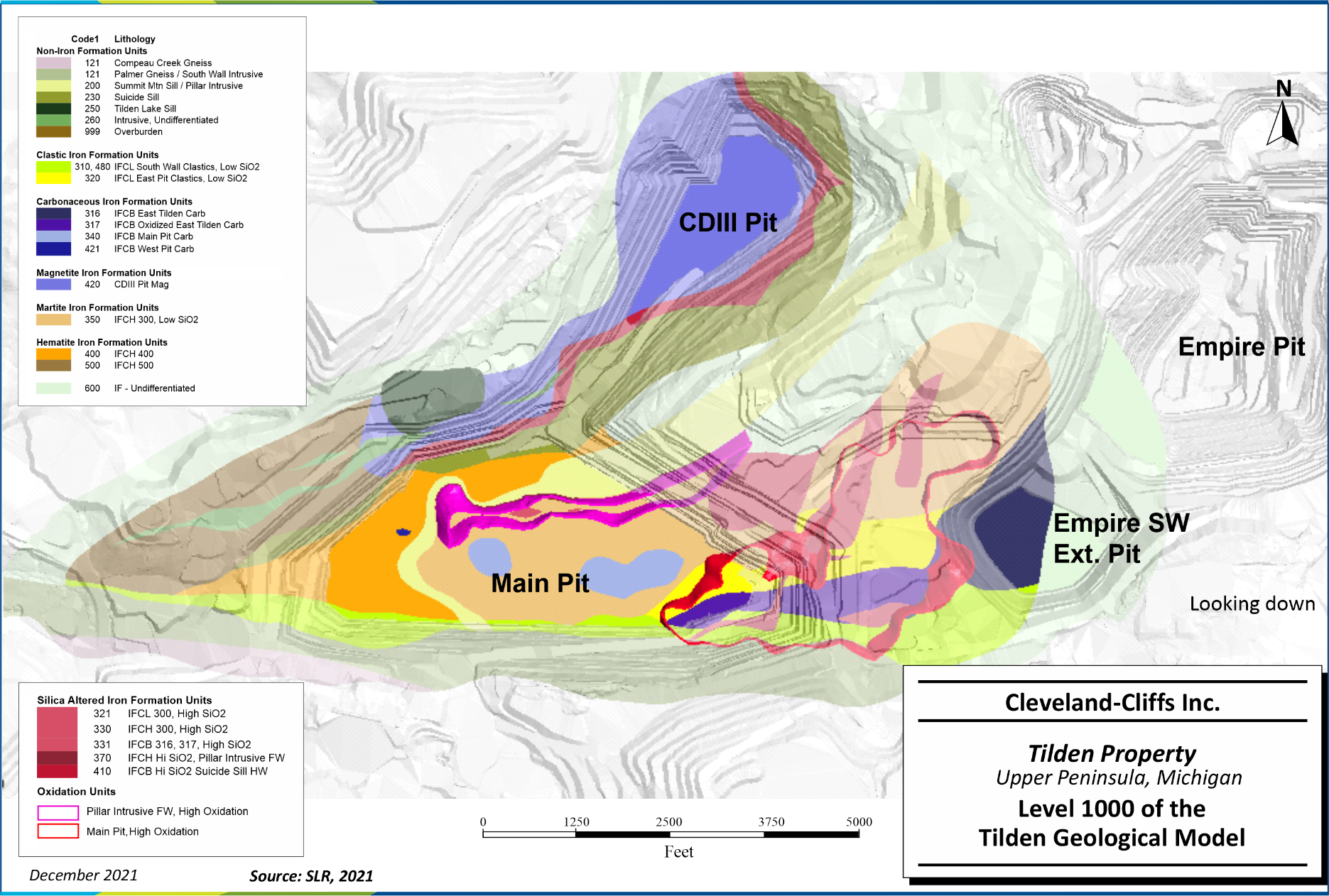

Figure 11-1: Level 1000 of the Tilden Geological Model | 75 |

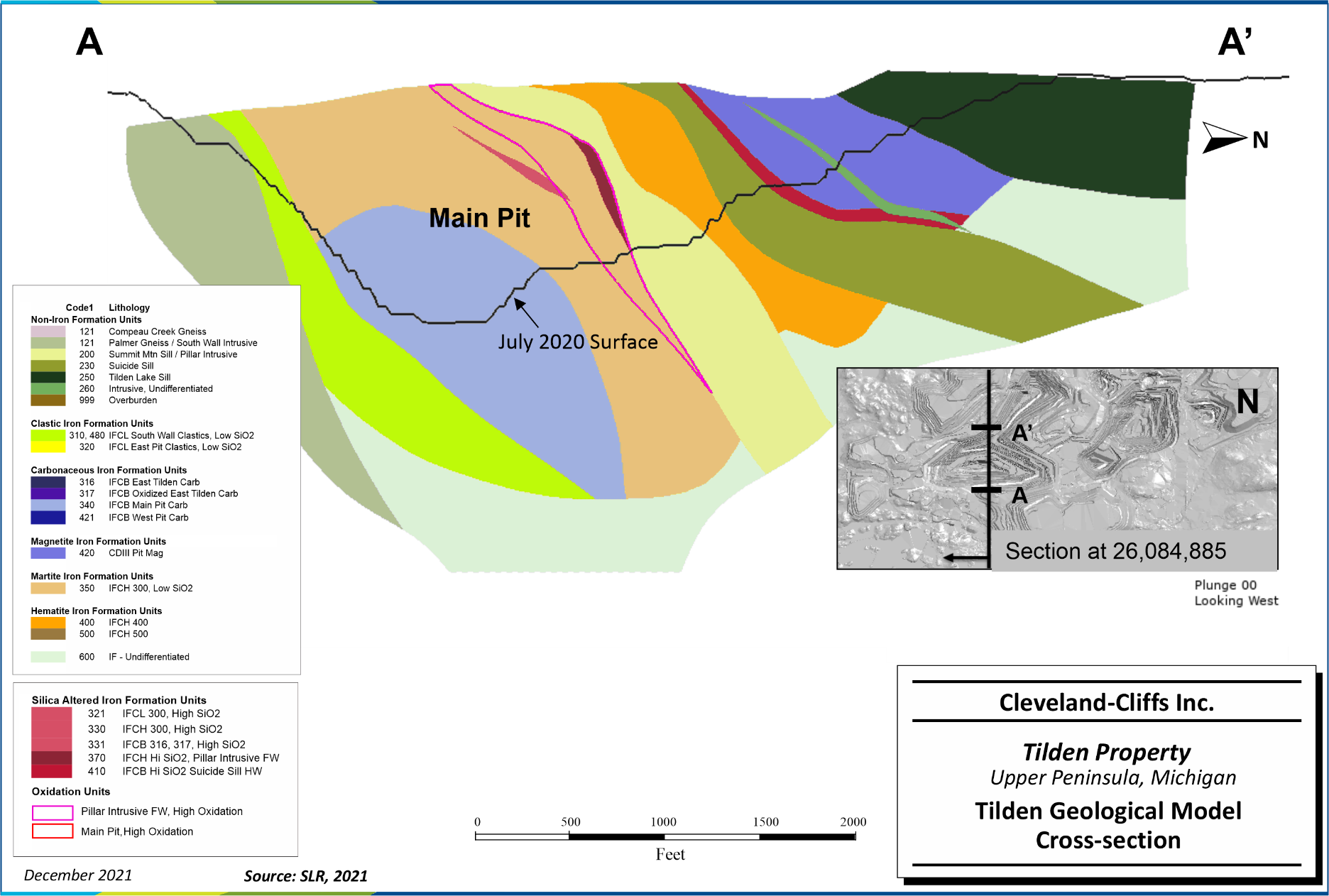

Figure 11-2: Tilden Geological Model Cross-section | 76 |

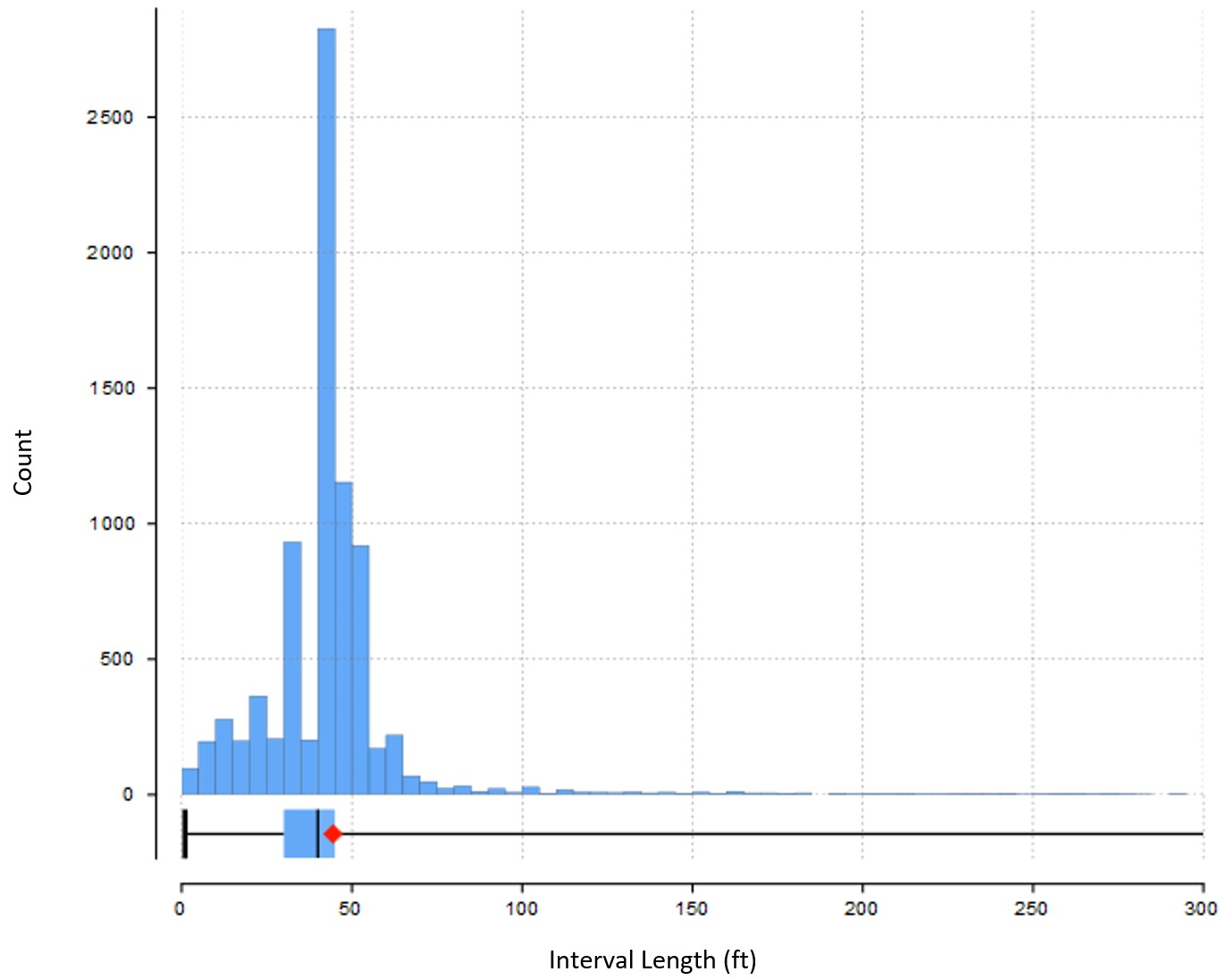

Figure 11-3: Histogram of Sample Length | 78 |

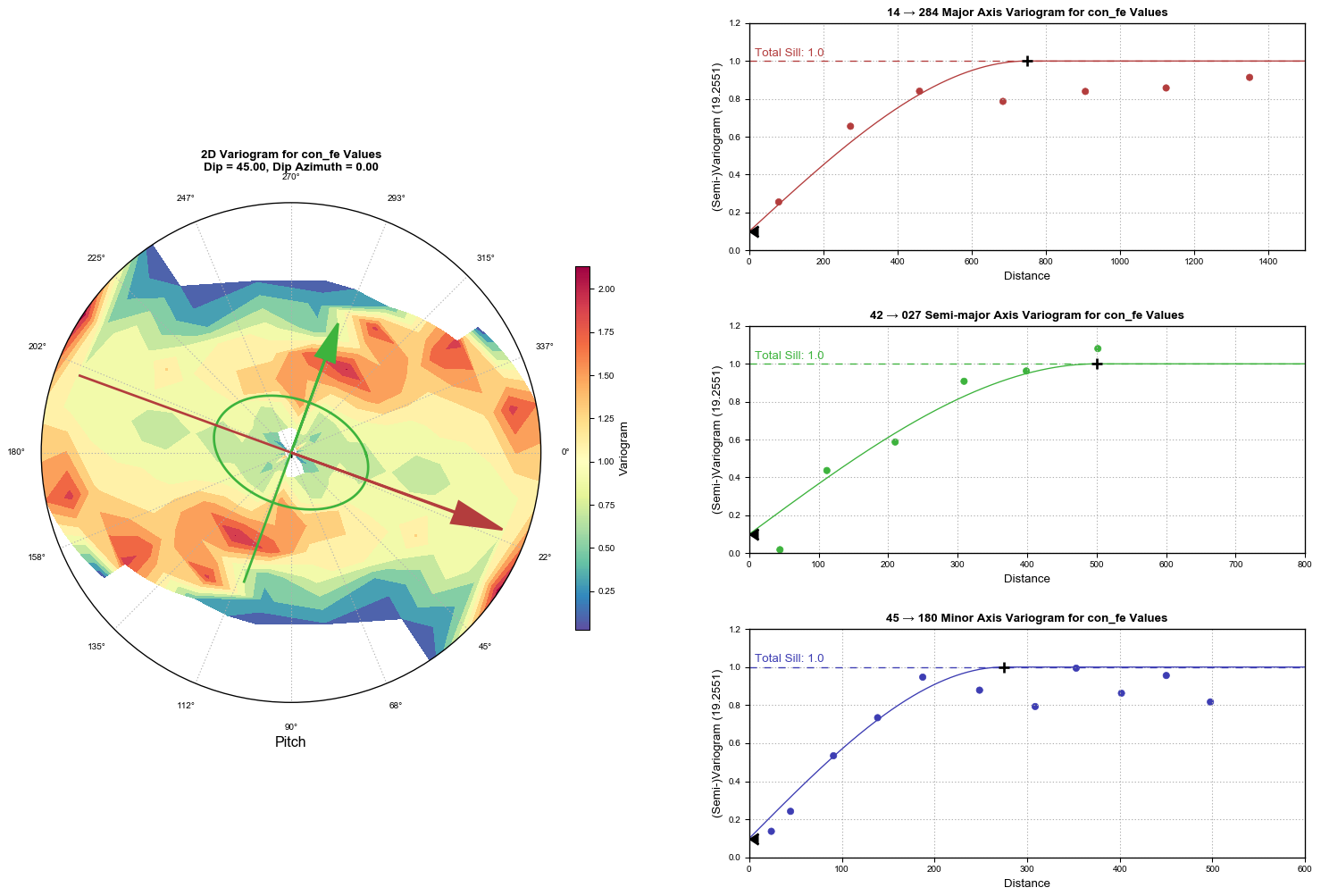

Figure 11-4: Radial Plot, Experimental Variogram and Model for confe Within IFCB Main Pit Carb (340) | 82 |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 vi

| | | | | |

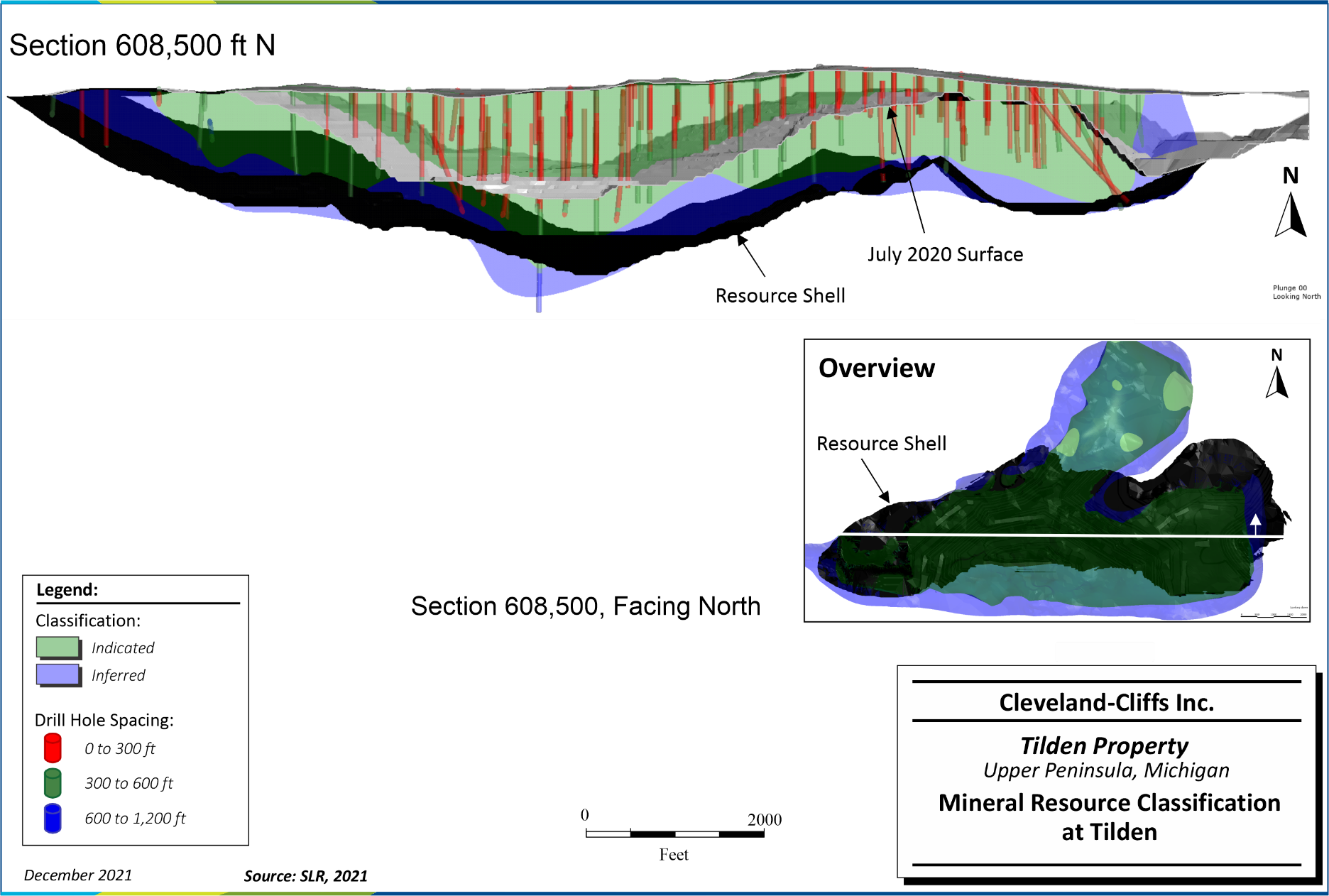

Figure 11-5: Mineral Resource Classification | 88 |

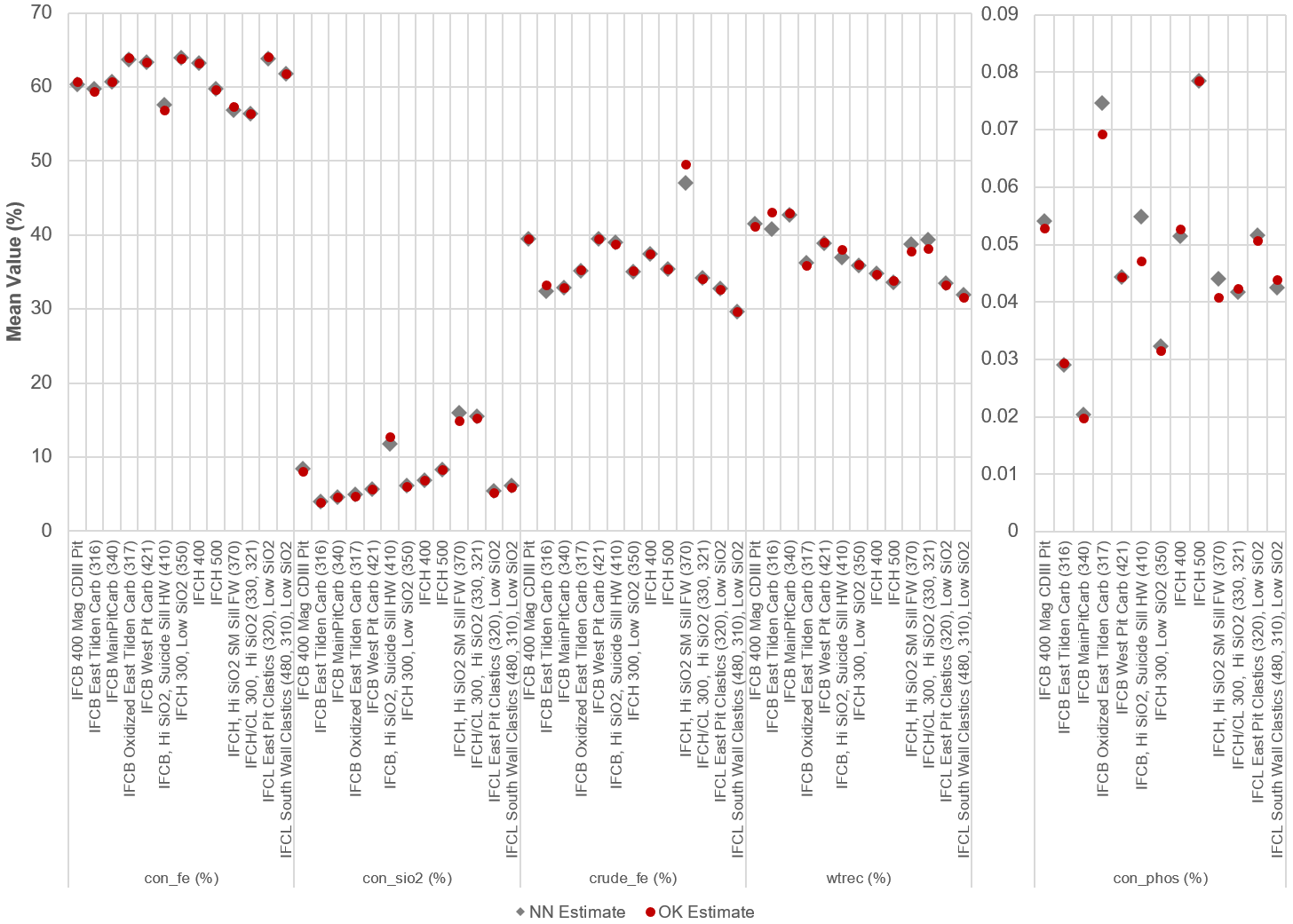

Figure 11-6: Comparison of OK and NN Estimates by Variable and Domain | 90 |

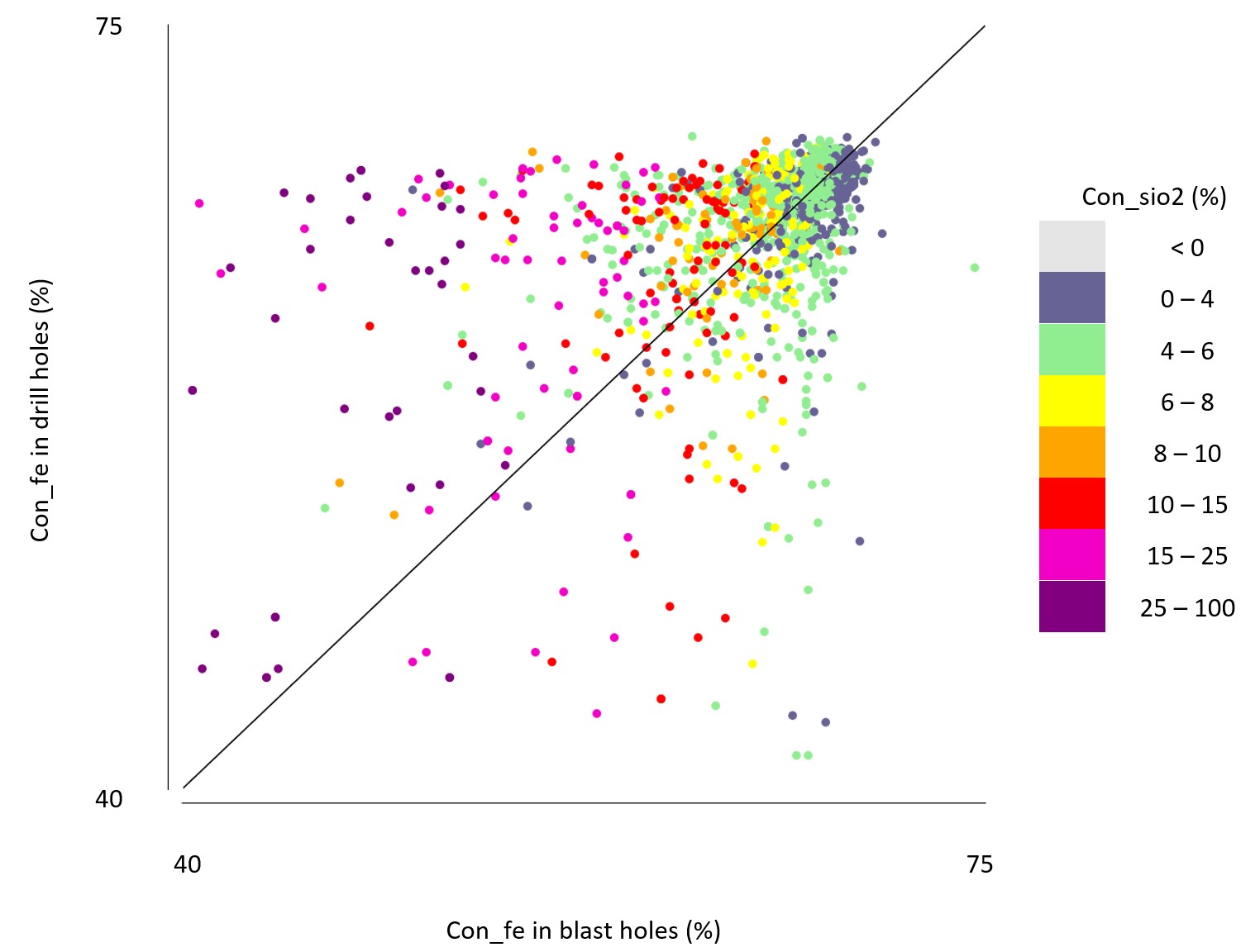

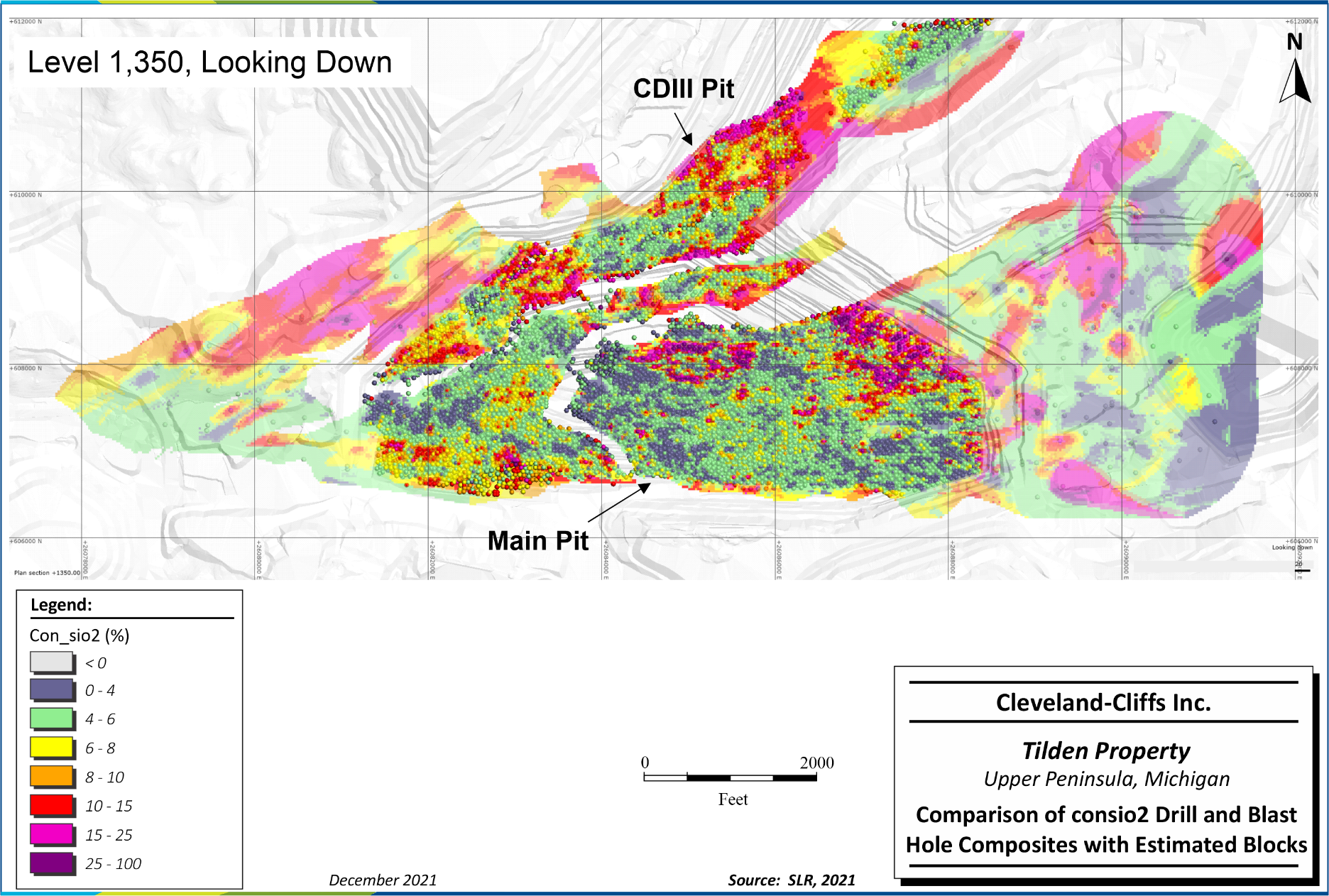

Figure 11-7: Comparison of consio2 Drill and Blast Hole Composites with Estimated Blocks | 91 |

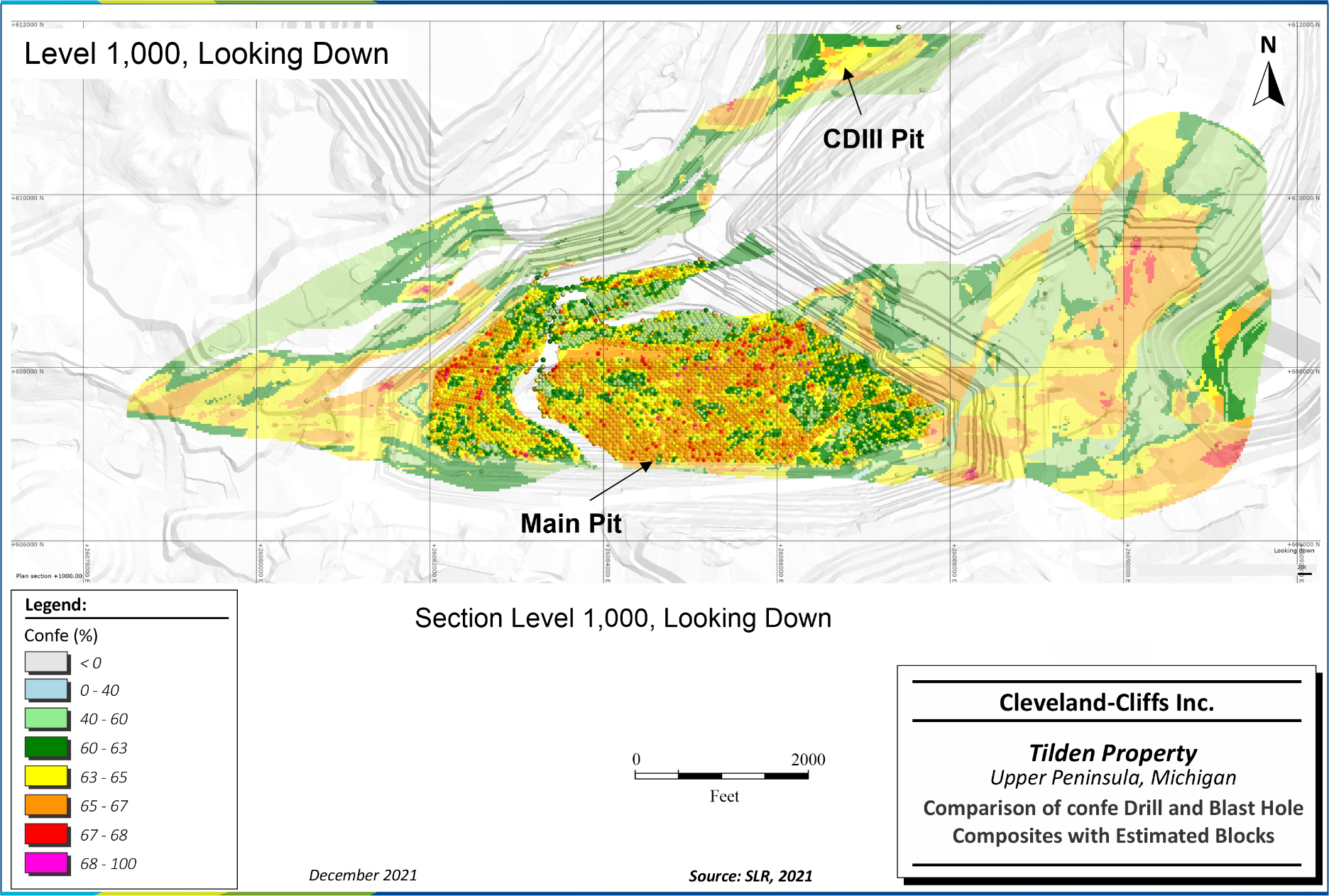

Figure 11-8: Comparison of confe Drill and Blast Hole Composites with Estimated Blocks | 92 |

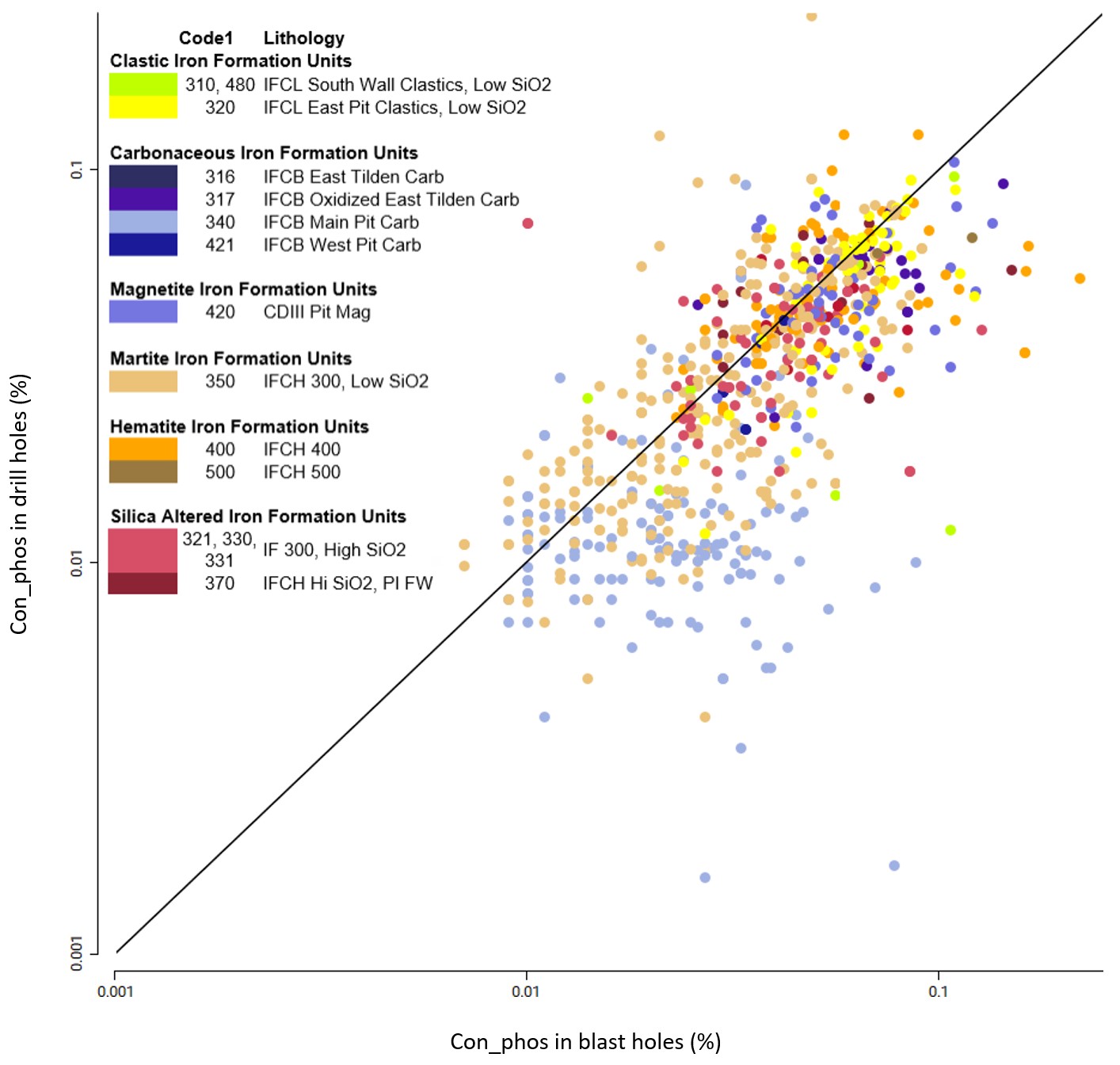

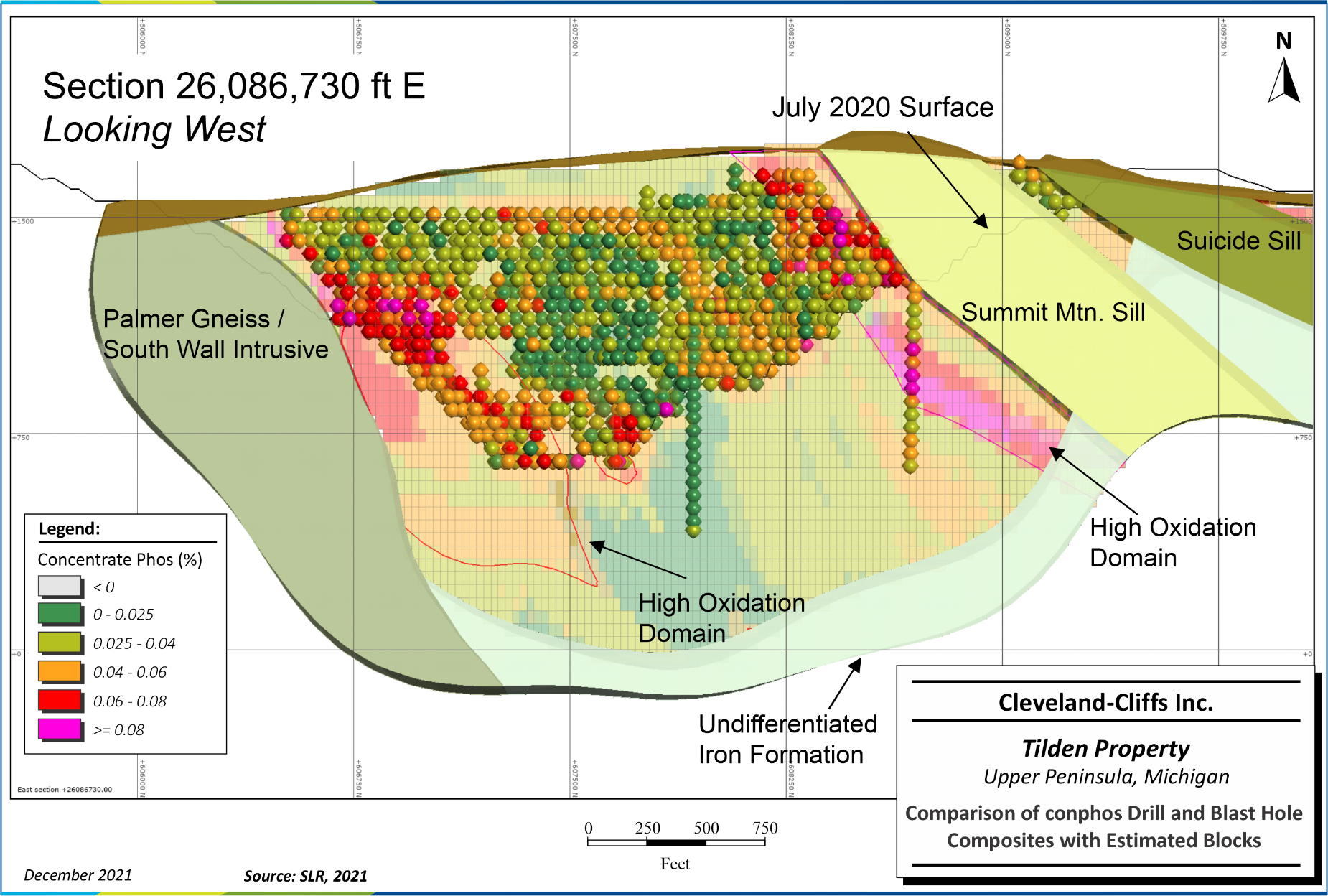

Figure 11-9: Comparison of conphos Drill and Blast Hole Composites with Estimated Blocks | 93 |

| |

| |

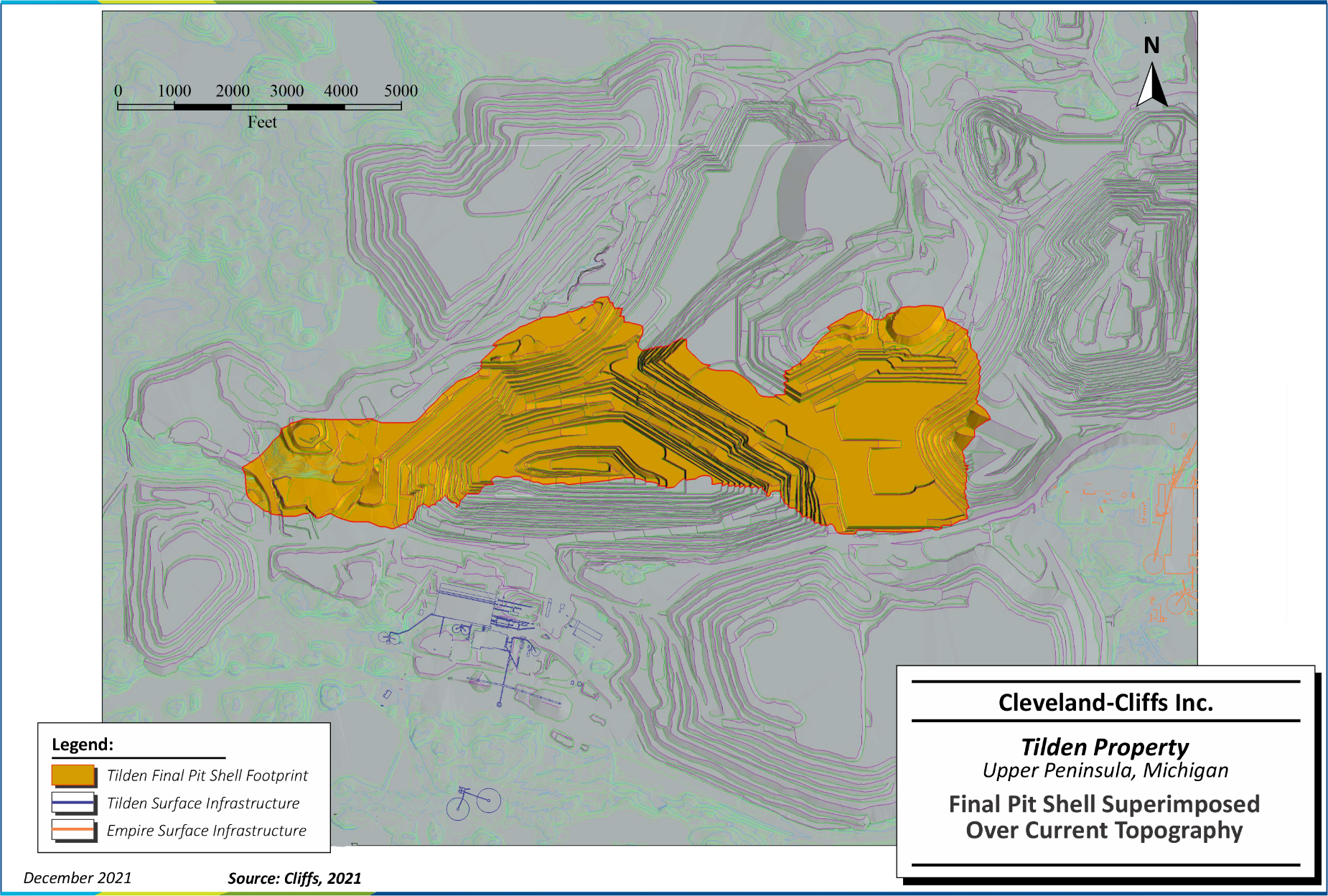

Figure 12-3: Final Pit Shell Superimposed Over Current Topography | 105 |

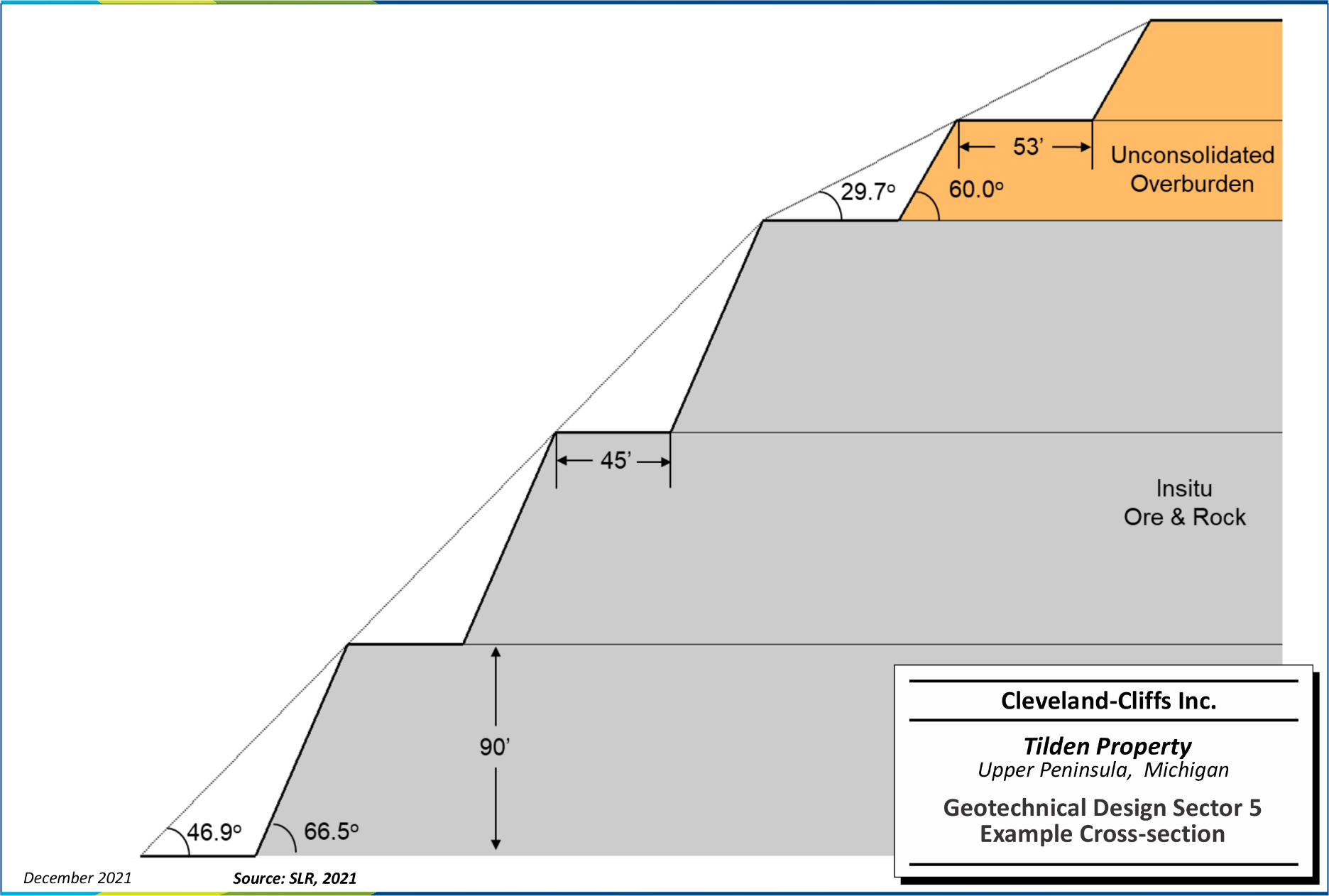

Figure 13-1: Geotechnical Design Sector 5 Example Cross-section | 110 |

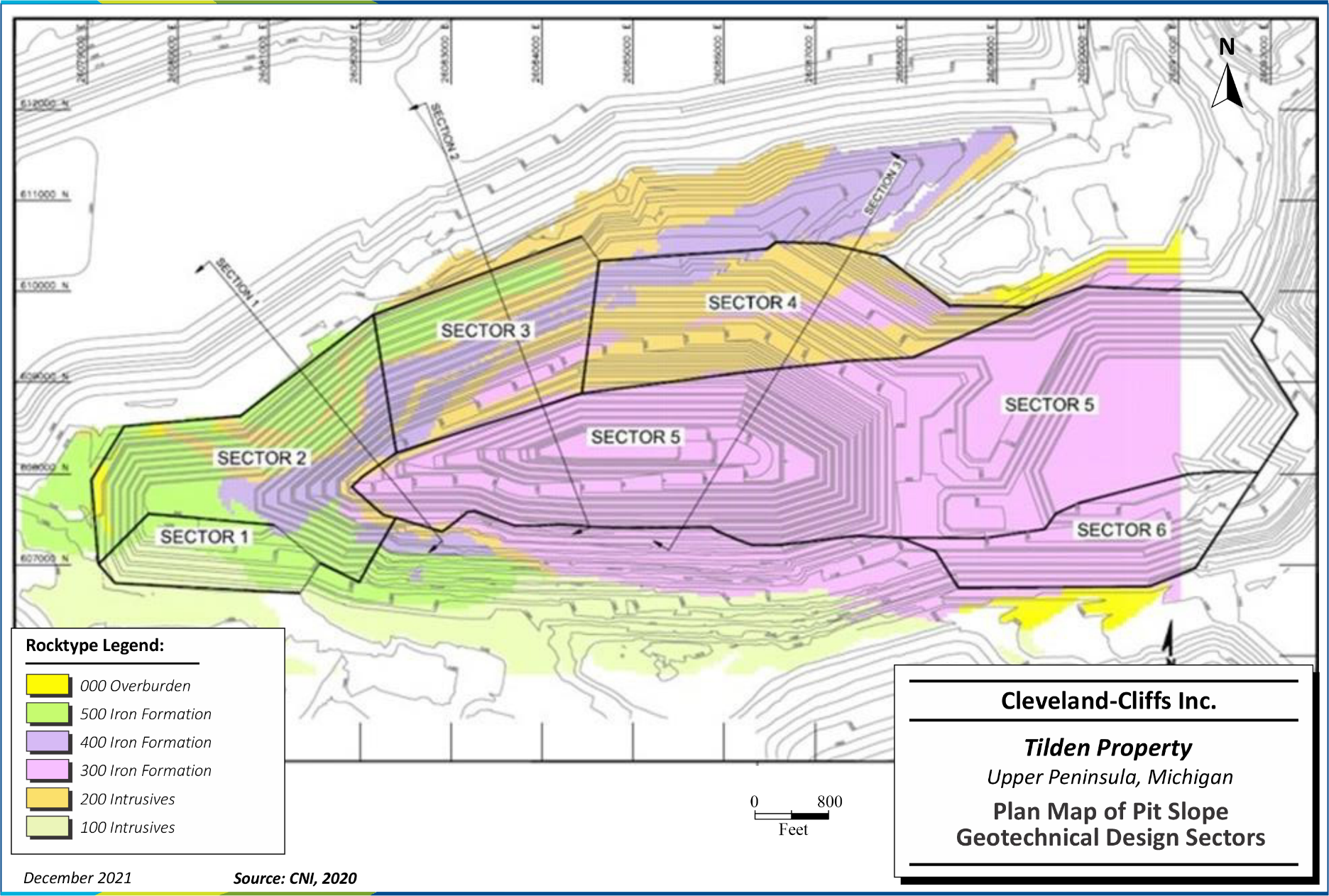

Figure 13-2: Plan Map of Pit Slope Geotechnical Design Sectors | 111 |

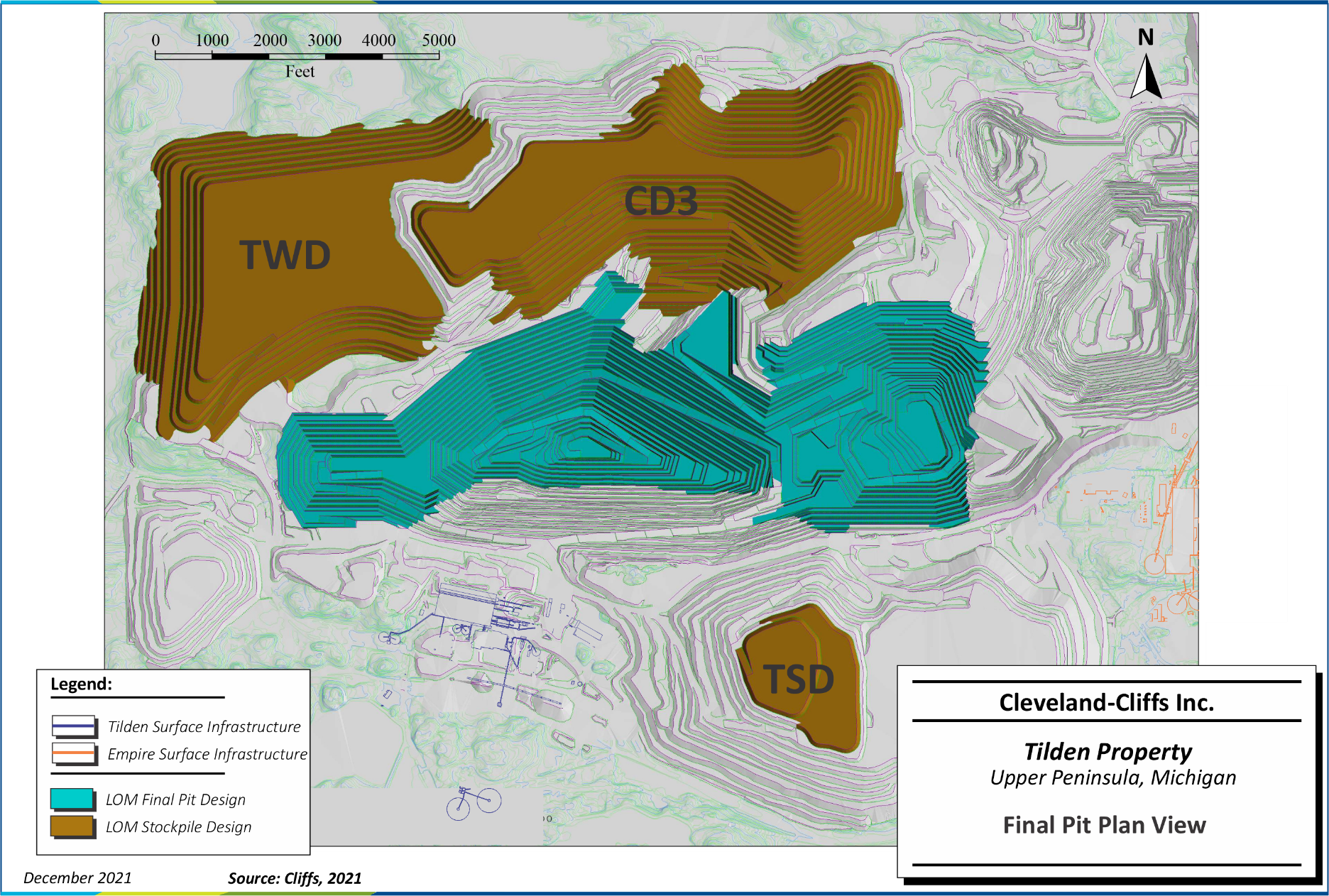

Figure 13-3: Final Pit Plan View | 116 |

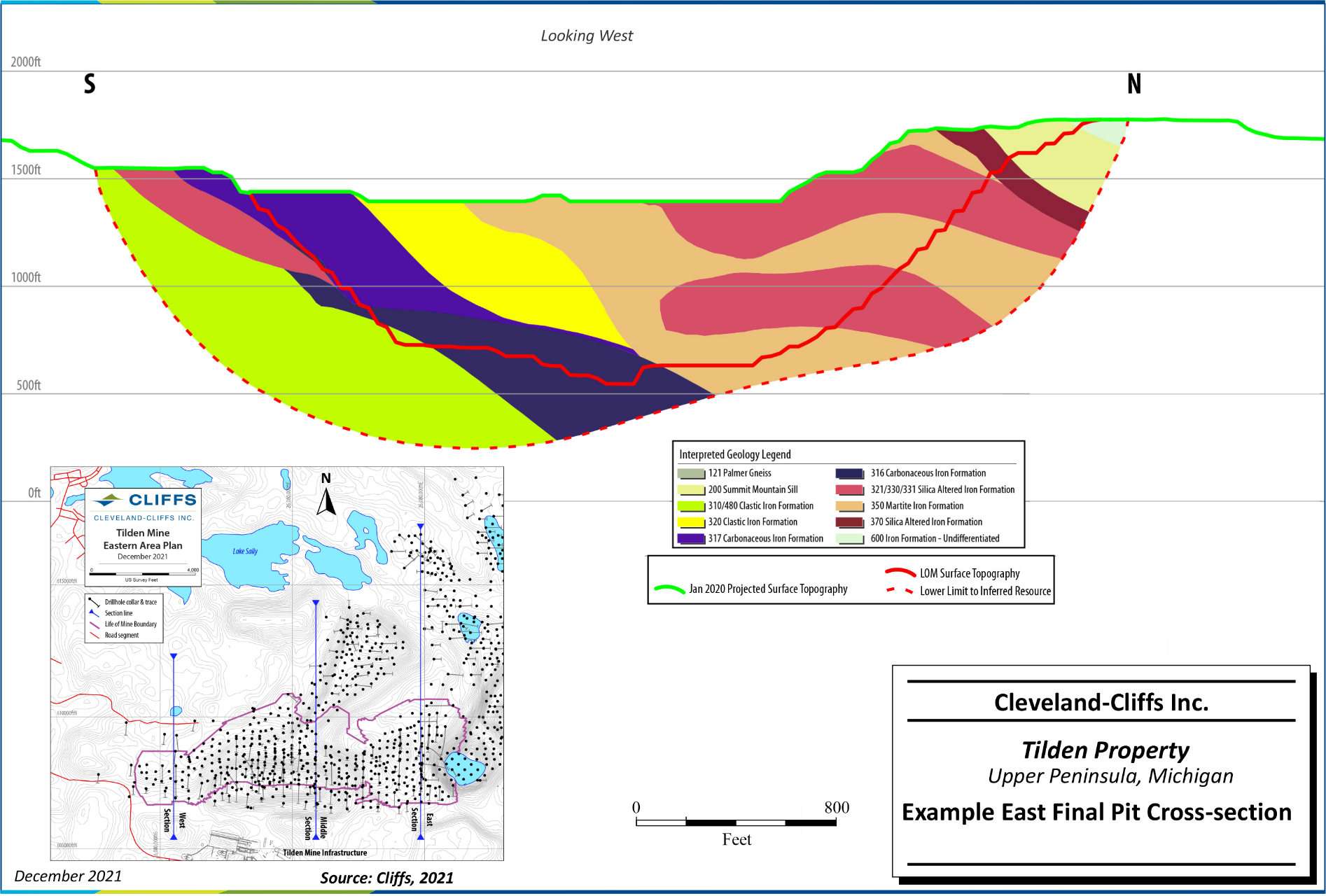

Figure 13-4: Example East Final Pit Cross-section Looking West | 117 |

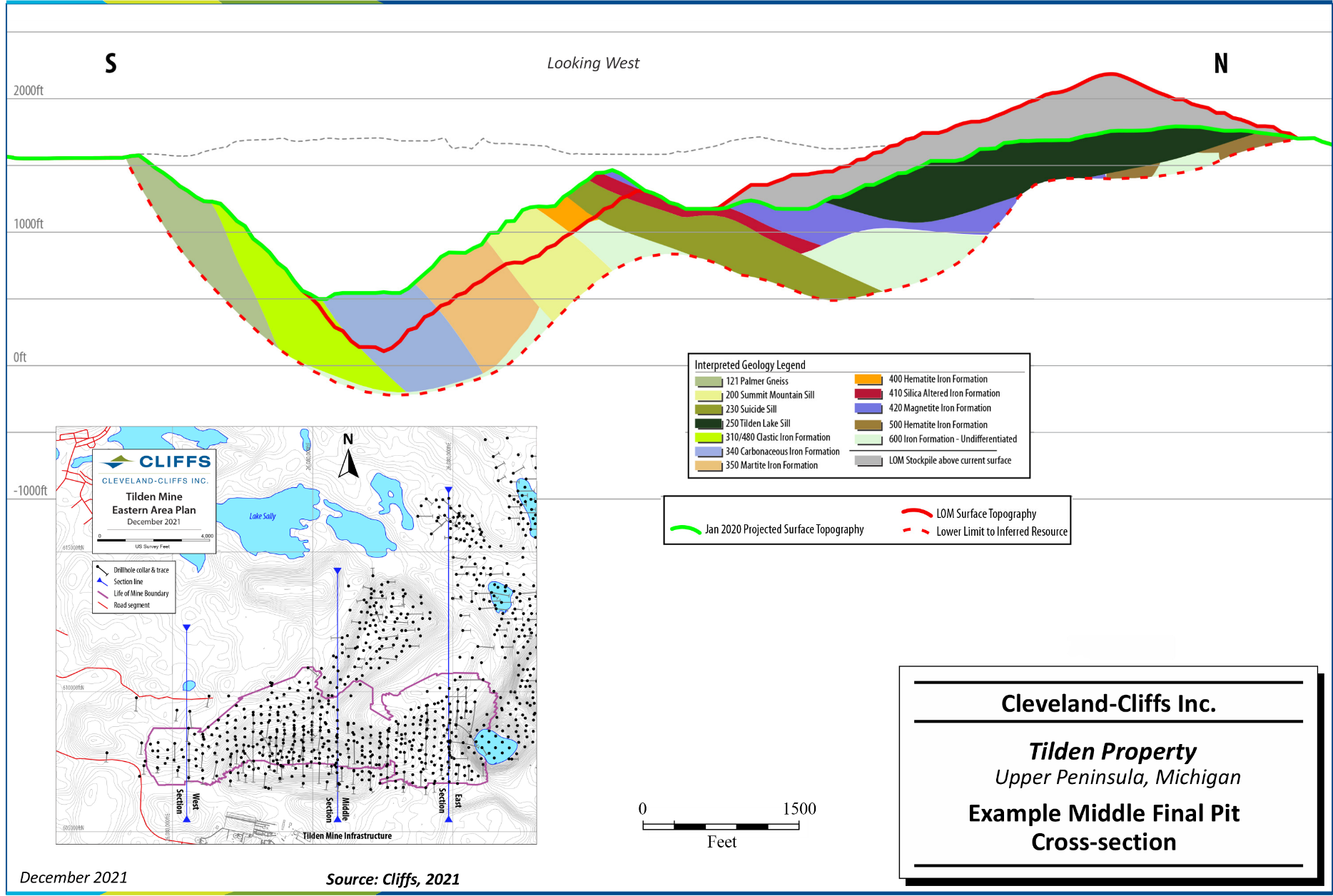

Figure 13-5: Example Middle Final Pit Cross-section Looking West | 118 |

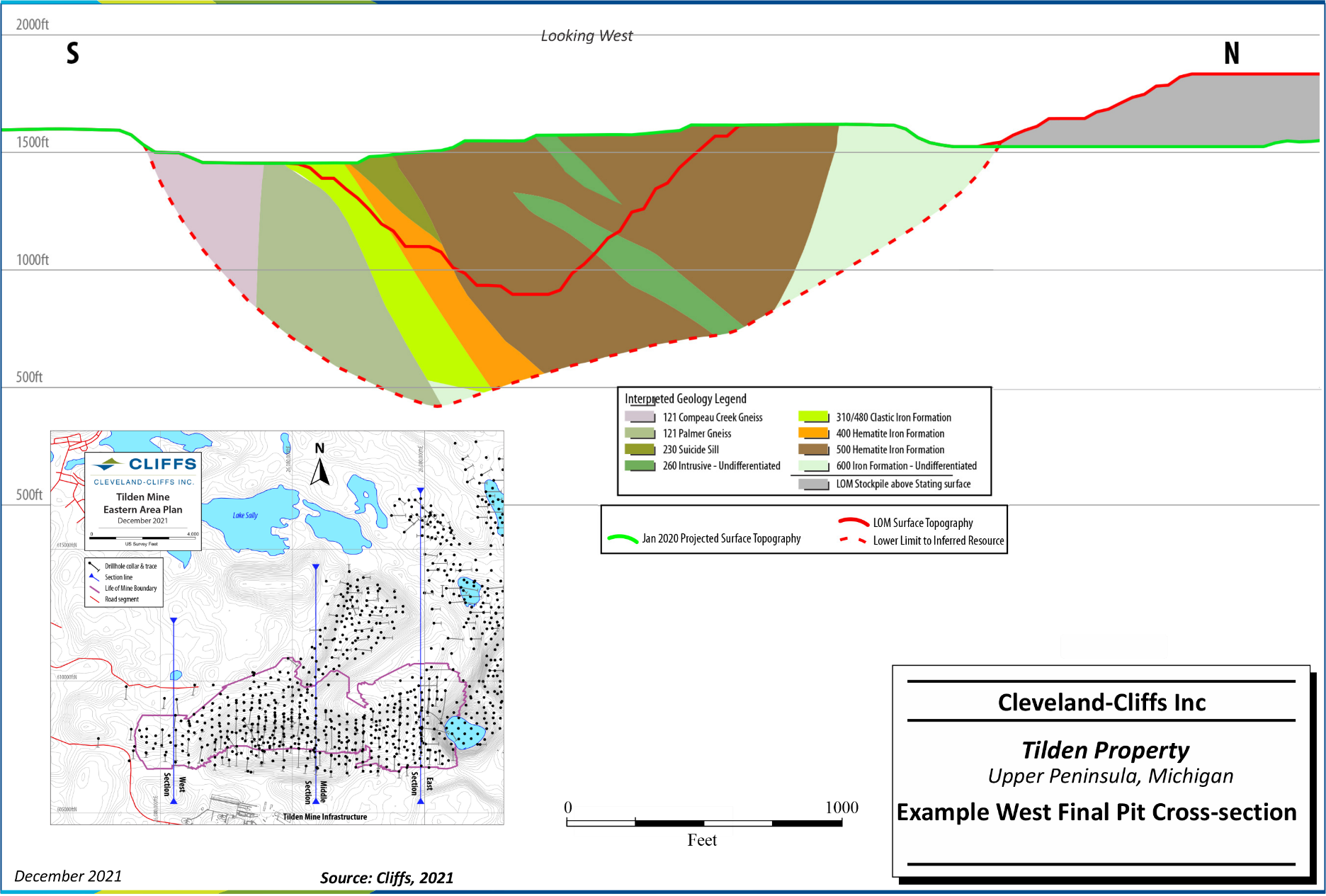

Figure 13-6: Example West Final Pit Cross-section Looking West | 119 |

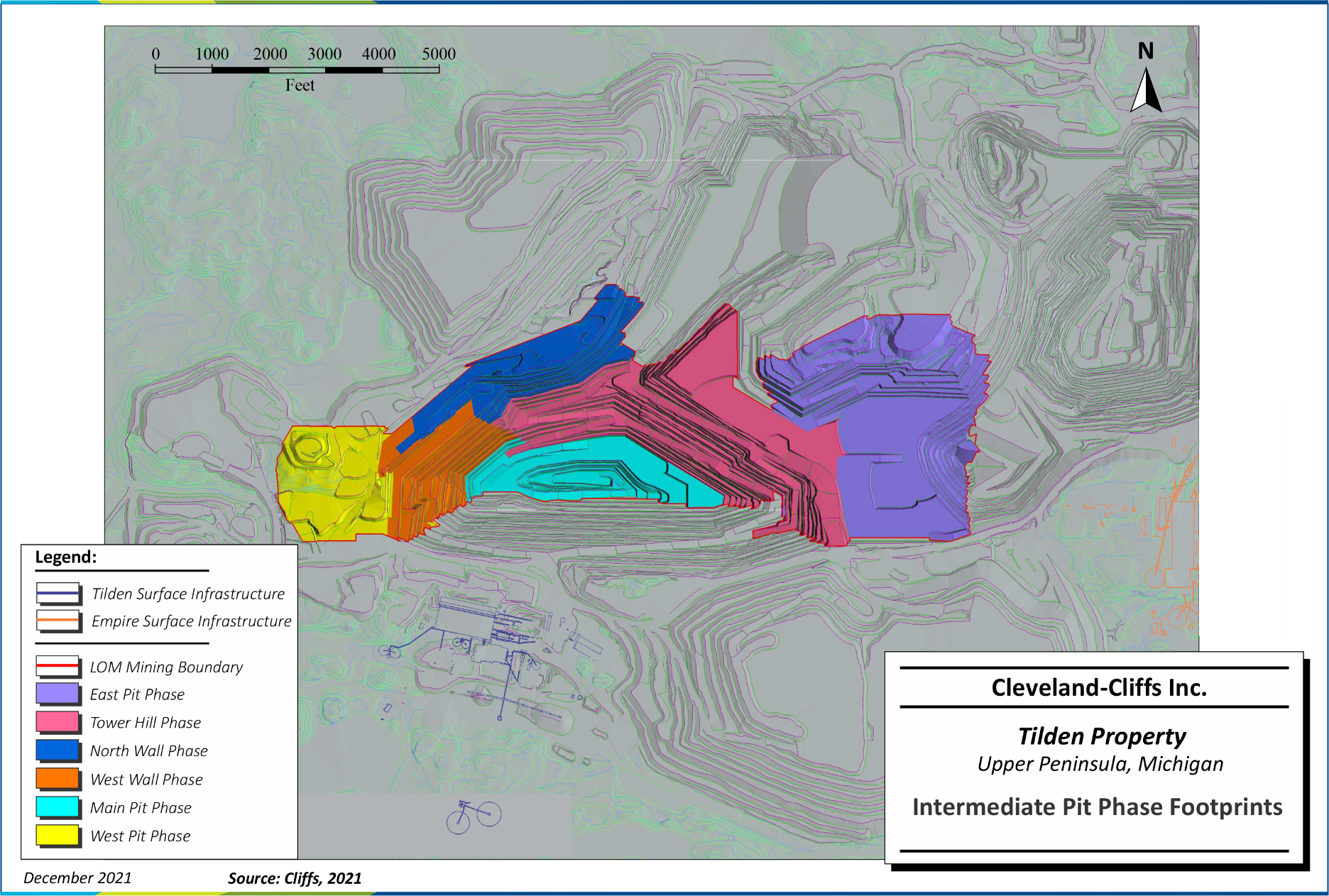

Figure 13-7: Intermediate Pit Phase Footprints | 121 |

Figure 13-8: Past and Forecast LOM Production | 124 |

Figure 13-9: Tilden Mine Stockpile Designs at Full Capacity | 126 |

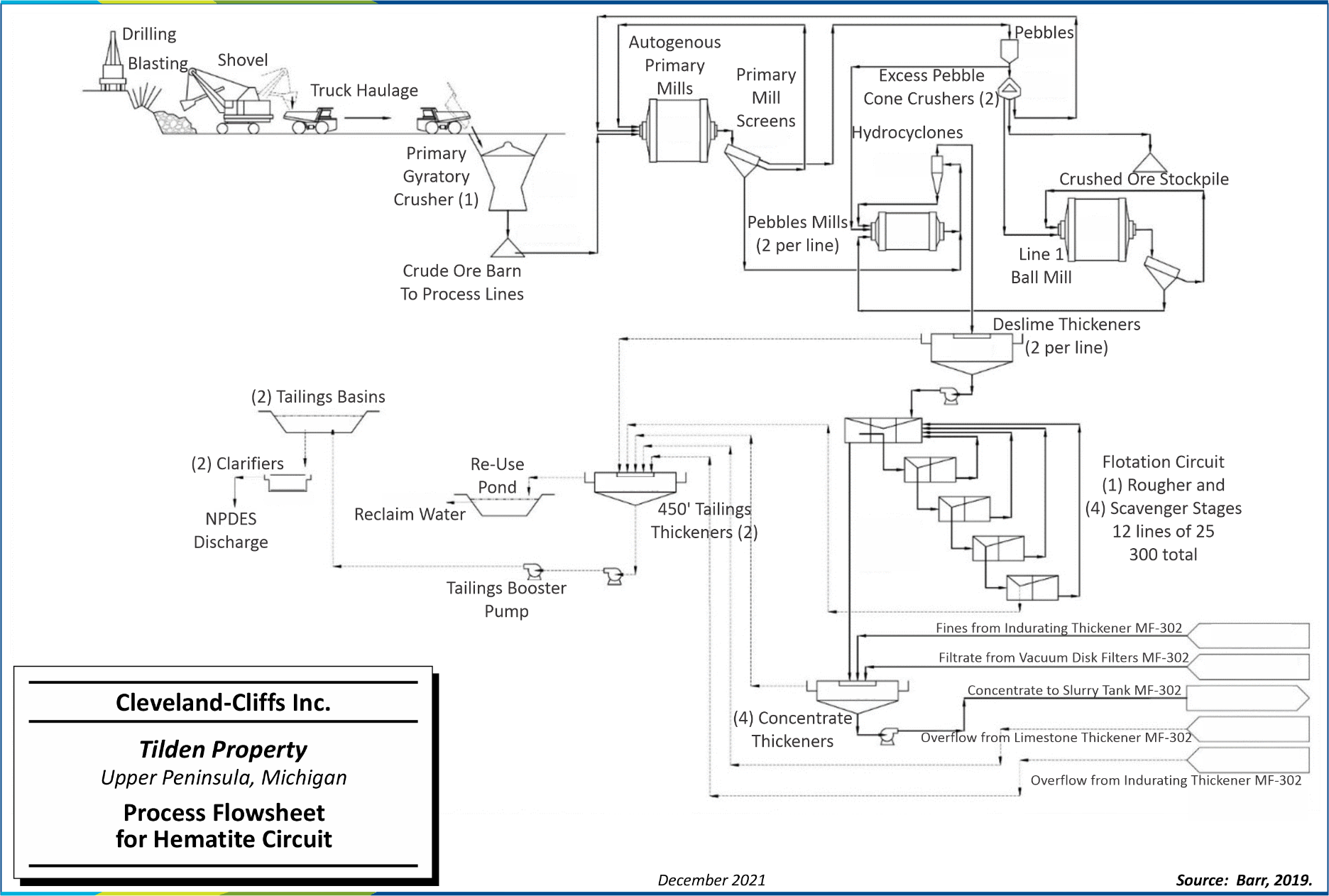

Figure 14-1: Hematite Circuit Process Flowsheet | 131 |

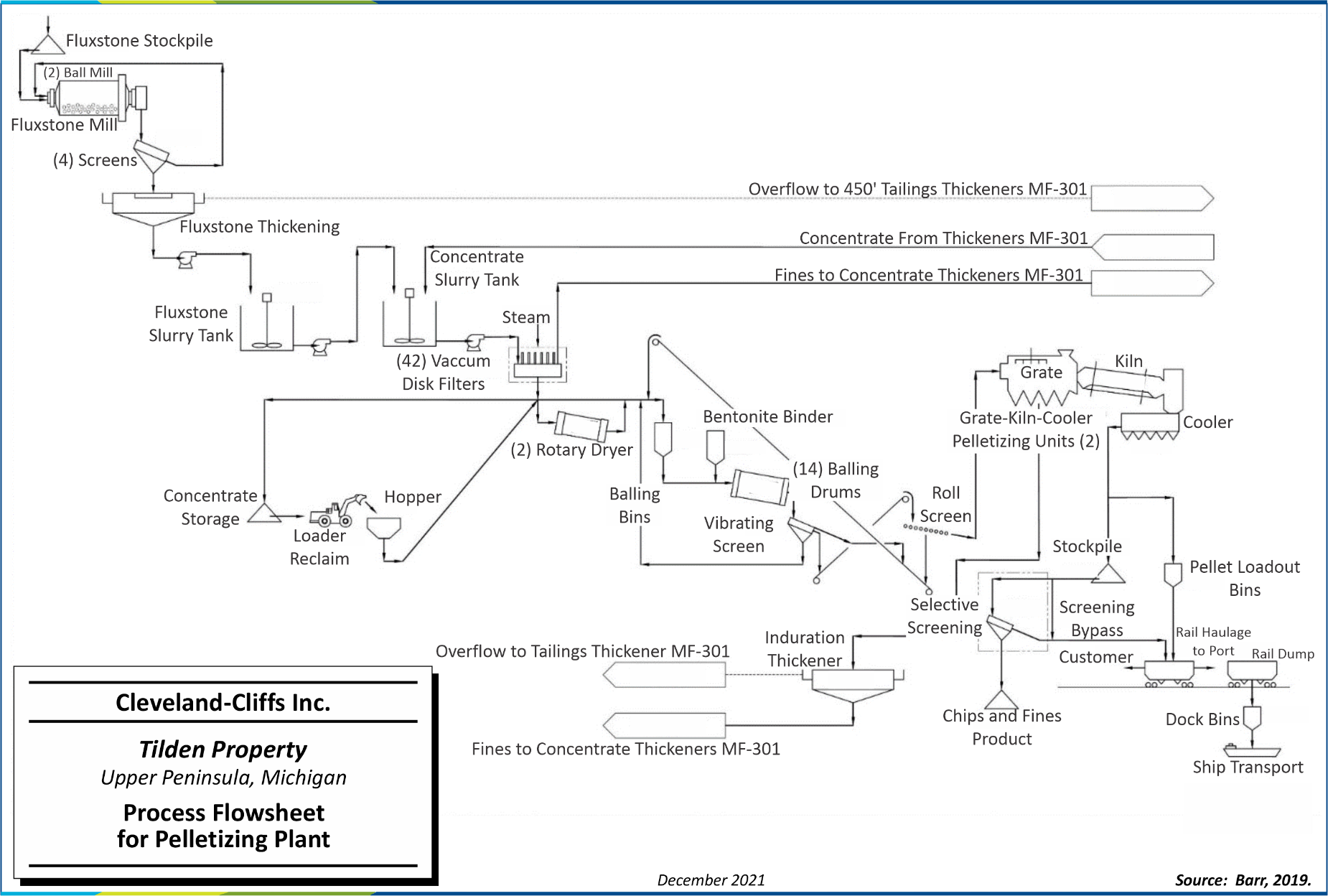

Figure 14-2: Process Flowsheet for Pelletizing Plant | 133 |

| |

| |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001Technical Report Summary - February 7, 2022 vii

1.0EXECUTIVE SUMMARY

1.1Summary

SLR International Corporation (SLR) was retained by Cleveland-Cliffs Inc. (Cliffs) to prepare an independent Technical Report Summary (TRS) for the Tilden Property (Tilden or the Property), located in Northern Michigan, USA. The owner of the Property, Tilden Mining Company L.C. (Tilden L.C.), is a wholly owned subsidiary of Cliffs.

The purpose of this TRS is to disclose year-end (YE) 2021 Mineral Resource and Mineral Reserve estimates for Tilden.

Cliffs is listed on the New York Stock Exchange (NYSE) and currently reports Mineral Reserves of pelletized ore in SEC filings. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. SLR visited the Property on October 24, 2019 and January 20 to 24, 2020.

The Property includes the Tilden Mine (the Mine) and processing facility (the Plant) located approximately five miles south of the city of Ishpeming, Michigan. The Property is also immediately west of Cliffs’ Empire Property, which was indefinitely idled in 2016. The Mine is a large, operating, open-pit iron mine and is unique among Cliffs’ US-owned operations because the primary ore mineral at Tilden is hematite, with other minerals being martite (oxidized pseudomorph of magnetite), goethite, and siderite (iron carbonate mineral), as opposed to strictly magnetite. The Property is also unique in the world in that the hematite-dominant ore is mined at a low grade, concentrated using a selective-flocculation desliming and flotation process, and pelletized.

The Property commenced operations in 1974 under a partnership of Algoma Steel, Stelco, J&L Steel, Wheeling-Pittsburgh Steel, Sharon Steel, and The Cleveland-Cliffs Iron Company (CCIC). The property has since been at least partially in the possession of a subsidiary of Cliffs. In 2001, Cliffs acquired Algoma Steel's 45% interest in Tilden L.C. In 2017, Cliffs became the sole owner of Tilden L.C.

The open-pit operation has a mining rate of approximately 21 million long tons (MLT) of ore per year and produces 7.7 MLT of iron ore pellets per year, which are mostly shipped by freighter via the Great Lakes to Cliffs’ steel mill facilities in the Midwestern USA, with some quantities shipped by rail to external customers.

1.1.1Conclusions

Tilden has successfully produced iron ore pellets for over 47 years. The update to the Mineral Resource and Mineral Reserve does not materially change any of the assumptions from previous operations. An economic analysis was performed using the estimates presented in this TRS and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves for a 25-year mine life.

SLR offers the following conclusions by area.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 1

1.1.1.1Geology and Mineral Resources

•Indicated Mineral Resources at Tilden, exclusive of Mineral Reserves, are estimated to total 135.4 MLT at a grade of 34.7% crude Fe. Inferred Mineral Resources are estimated to total 350.4 MLT at a grade of 34.7% crude Fe.

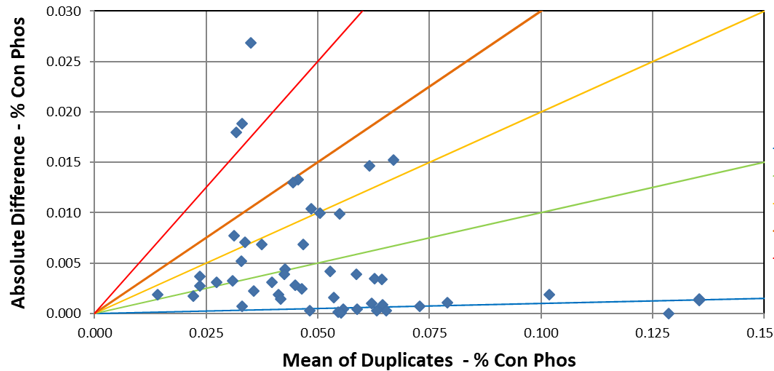

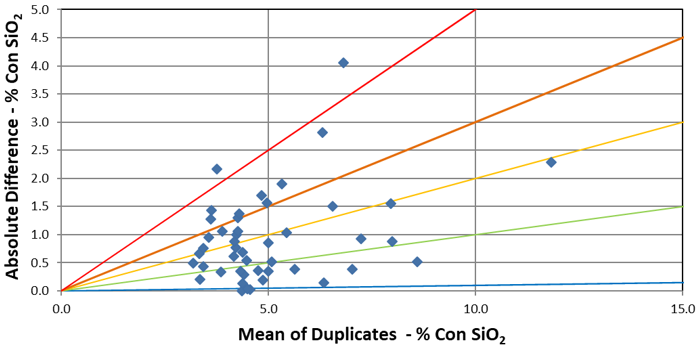

•The 2019 quality assurance and quality control (QA/QC) program as designed and implemented by Cliffs has been helpful to understand the precision and accuracy of sample analysis at the Tilden laboratory, which is used to support the assay results within the database and confirm that the database is suitable for use in estimating Indicated and Inferred Mineral Resources.

•The Tilden database is adequate for the purposes of estimating Indicated and Inferred Mineral Resources. The lack of regular QA/QC sample submissions alongside samples used to support Mineral Resources is outside of industry-standard practice, and there are several database integrity issues that require attention.

•There is a moderate to good correlation of all variables between drill and blast hole twinned samples. Correlation of iron content values decreases for samples with high silica in concentrate values. There is a potential high bias of phosphorus in concentrate values in favor of blast holes. The known bias of weight recovery (wtrec) in favor of blast hole data is not observable in the paired dataset.

•The estimated block grades reflect the local blast hole or drill hole composite value, and the trends of the different variables are as intended.

1.1.1.2Mining and Mineral Reserves

•The Property has been in production since 1974, and specifically under 100% Cliffs operating management since 2017. Cliffs conducts its own Mineral Reserve estimations.

•Total Proven and Probable Mineral Reserves are estimated at 520.0 MLT of crude ore at a grade of 34.7% crude Fe.

•Mineral Reserve estimation practices follow industry standards.

•The Mineral Reserve estimate indicates a sustainable project over a 25-year life of mine (LOM).

•The geotechnical design parameters used for pit design are reasonable and support previous operations. Slope depressurization may be required as part of the development of the final pit walls.

•The LOM production schedule is reasonable and incorporates large mining areas and open benches.

•An appropriate mining equipment fleet, maintenance facilities, and manpower are in place, with additions and replacements estimated, to meet the LOM production schedule requirements.

•Sufficient storage capacity for waste stockpiles and tailings has been identified to support the production of the Mineral Reserve.

1.1.1.3Mineral Processing

•The Tilden deposit is complex and requires metallurgical testing to classify materials as ore and waste. A standard flotation testing procedure has been developed for material classification, resource modeling, and concentrator feed blending.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 2

•The capacity of the Tilden concentrator and pellet plant is 7.7 MLT per year (MLT/y) of fluxed pellets (hemflux) from hematite-dominant crude ore sources.

•The ore is amenable to autogenous grinding (AG), and the concentrator consists of eleven lines of primary autogenous mills for coarse grinding and pebble mills for fine grinding, eliminating the requirement for steel grinding media.

•Pellets are indurated using a gas- and coal-fired grate drying and preheating furnace, followed by gas- and coal-fired rotary kilns for fusing and hardening, and rotary coolers for cooling. Heat must be supplied by fuel for low-magnetite concentrates, without the benefit of the exothermic heat of reaction from magnetite oxidation to hematite during heating.

•Crude iron ore head grades feeding the Plant during 2014 to 2020 ranged from 34.4% Fe to 35.5% Fe. Iron recovery to flotation concentrates ranged from 69.6% to 74.8%, with concentrate grades averaging 62.2% to 63.7% during this period. Approximately 20.5 MLT of crude ore is processed through the concentrator annually to produce 8.9 MLT of fluxed concentrate and 7.7 MLT of fluxed pellets (hemflux).

1.1.1.4Infrastructure

•The Property is in a historically important, iron-producing region of Northern Michigan. All the infrastructure necessary to mine and process commercial quantities of iron ore and produce and ship pellets is in place, including the Mine, concentrator, and support facilities, line power supplies, natural gas sourced from an interstate pipeline system, local supply of coal, and diesel fuel supply from Green Bay, Wisconsin.

•The Gribben Tailings Basin (GTB) is located approximately five miles southeast of the Tilden concentrator plant and nine miles from Lake Superior. The GTB is comprised of two, ring dike-type impoundments: the Gribben North Tailings Basin (GNTB), which encompasses approximately 1,350 acres, and the Gribben South Tailings Basin (GSTB), which encompasses approximately 1,100 acres.

1.1.1.5Environment

•Tilden indicated that it maintains the requisite state and federal permits and is in compliance with all permits. Various permitting applications have been submitted to authorities and are pending authorization. Environmental liabilities and permitting are further discussed in Section 17.0.

1.1.2Recommendations

1.1.2.1Geology and Mineral Resources

1.Complete a reconciliation study to support the inclusion of Measured Mineral Resources at Tilden.

2.Complete additional drilling to improve the understanding of the deposit at its periphery and at depth, with a focus on low drill density areas within the 2019 LOM plan, as well as in areas with increased variability, such as the high-silica zones in the east of the Main Pit. Integrate the downhole information from the Empire and Tilden mines into a single, valid database.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 3

3.Develop a standard operating procedure for detailed logging of drill core that captures iron speciation, alteration, mineralogy, structure, and lithology. Retain initial geological observations in drill core separately from subsequent re-interpretations based on metallurgical results or results of neighboring drill holes.

4.Undertake a study where samples are consistently taken at shorter intervals, broken by geology, to examine how the variance of the assays is affected and how the material-type designation, based on a calculation of those variables, compares against the material-type designation of longer samples. Sample intrusive material (dilution) too small to be segregated when modeling or mining as part of iron formation unit samples.

5.Continue work to define fault orientations and related alteration in the east of the Main Pit to confirm the syn-bedding and cross-cutting directions of the modeled, high-silica alteration units and investigate alternative tools to capture drill hole information, including a magnetometer and hyperspectral and x-ray fluorescence handheld devices to allow empirical measurements of magnetism (where relevant), alteration, such as clay, and iron speciation.

6.Develop and implement a robust QA/QC program at Tilden for both exploration drill hole and blast hole samples and incorporate analytical attribute data, such as grind time, starch type, and dates into the assay database, to be able to analyze results in context of changing test protocols for performance and bias.

7.Address capacity issues at the Tilden laboratory to allow the sample analysis to be completed in a timely manner and to facilitate the inclusion of QA/QC samples.

1.1.2.2Mining and Mineral Reserves

1.Assess groundwater conditions in the immediate vicinity of the final pit through a more focused groundwater model. The results of this assessment should be input into an update of the pit slope stability analysis on sections cut through the current final pit design.

1.1.2.3Mineral Processing

1.Continue specialized metallurgical testing to support resource modeling and mine planning and blending for the concentrator.

2.Plant operational performance including concentrate and pellet production and pellet quality continues to be consistent year over year. It is important to maintain diligence in process-oriented metallurgical testing and in plant maintenance.

1.1.2.4Infrastructure

1.Prioritize the completion of an Operations, Maintenance, and Surveillance (OMS) Manual for the tailings storage facility (TSF) with the Engineer of Record (EOR) in accordance with Mining Association of Canada (MAC) guidelines and other industry-recognized standard guidance for tailings facilities.

2.Document, prioritize, track, and close out in a timely manner the remediation, or resolution, of items of concern noted in TSF audits or inspection reports.

3.Assess the impacts of depositing tailings in the Empire facility, and prepare the necessary design and permitting documents.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 4

1.2Economic Analysis

1.2.1Economic Criteria

An un-escalated technical-economic model was prepared on an after-tax, discounted cash flow (DCF) basis, the results of which are presented in this subsection. Key criteria used in the analysis are discussed in detail throughout this TRS. General assumptions used are summarized in Table 1-1, with all pellets reported per wet long ton (WLT) pellet.

Table 1-1: Technical-Economic Assumptions

Cleveland-Cliffs Inc. – Tilden Property

| | | | | |

| Description | Value |

| Start Date | December 31, 2021 |

| Mine Life | 25 years |

| Three-Year Trailing Average Revenue | $98/WLT Pellet |

| Operating Costs | $66.00/WLT Pellet |

| Sustaining Capital Costs (after five years) | $4/WLT Pellet |

| Discount Rate | 10% |

| Discounting Basis | End of Period |

| Inflation | 0.0% |

| Federal Tax Rate | 20% |

| State Tax Rate | None – Sales made out of state |

Table 1-2 presents a summary of the estimated mine production over the 25-year LOM.

Table 1-2: LOM Production Summary

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | |

| Description | Units | Value |

| Run of Mine (ROM) Ore | MLT | 520.0 |

| Total Material | MLT | 1,116.9 |

| Fe Grade | % | 34.7 |

| Average Annualized Mining Rate | MLT/y | 44 |

| Maximum Annualized Mining Rate | MLT/y | 62 |

Table 1-3 presents a summary of the estimated plant production over the 25-year LOM.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 5

Table 1-3: LOM Plant Production Summary

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | |

| Description | Units | Value |

| ROM Material Milled | MLT | 520.0 |

| Average Annualized Processing Rate | MLT/y | 20.8 |

| Process Recovery | % | 37.0 |

| Total Hemflux Pellet | MLT | 192.4 |

| Annual Hemflux Pellet Production | MLT/y | 7.7 |

1.2.2Cash Flow Analysis

The indicative economic analysis results, presented in Table 1-4, indicate an after-tax Net Present Value (NPV), using a 10% discount rate, of $1,325 million at an average blended wet pellet price of $98/WLT. SLR notes that Internal Rate of Return (IRR) is not applicable, as the Property has been in operation for a number of years. Capital identified in the economics is for sustaining operations and plant rebuilds as necessary.

The economic analysis was performed using the estimates presented in this TRS and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves.

Table 1-4: LOM Indicative Economic Results

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | |

| Description | US$ Millions | US$/WLT Pellet |

| Three-Year Trailing Revenue ($/WLT Pellet) | | 98 |

| Pellet Production (MWLT) | 192.4 | |

| Gross Revenue | 18,854 | |

| Mining | (2,944) | 15.30 |

| Processing | (8,233) | 42.79 |

| Site Administration | (547) | 2.84 |

| General / Other Costs | (975) | 5.07 |

| Total Operating Costs | 12,698 | 66.00 |

| Operating Income (excl. D&A) | 6,156 | 32.00 |

| Federal Income Tax | (1,231) | (6.40) |

| Depreciation Tax Savings | 209 | 1.09 |

| Accretion Tax Savings | 13 | 0.07 |

| Net Income after Taxes | 5,146 | 26.75 |

| Capital | (894) | (4.65) |

| Closure Costs | (57) | (0.30) |

| Cash Flow | 4,196 | 21.81 |

| NPV 10% | 1,322 | |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 6

1.2.3Sensitivity Analysis

The Tilden operation is nominally most sensitive to market prices (revenues) followed by operating cost. For each dollar movement in sales price or operating cost, respectively, the after-tax NPV changes by approximately $56 million.

1.3Technical Summary

1.3.1Property Description

The Property is located in Marquette County in Michigan’s Upper Peninsula, USA, on the Marquette Iron Range, approximately five miles south of the city of Ishpeming, Michigan at latitude 46° 29' N and longitude 87° 40' W. The Property is also immediately adjacent to Cliffs’ indefinitely idled Empire Mine and processing facility. The Mine and Plant have the capacity to produce approximately 7.7 MLT of iron ore pellets annually.

Land ownership and mineral leases are held by Tilden L.C. Cliffs, through its subsidiary CCIC, owns 100% of the surface and mining rights. In addition, Cliffs owns 100% of Tilden L.C. Tilden L.C. owns 21,100 acres of surface rights and 2,470 acres of mineral leases in Marquette County.

1.3.2Accessibility, Climate, Local Resources, Infrastructure, and Physiography

The Property can be accessed from the west through the Tilden entrance gate near the community of National Mine, located two miles south of Ishpeming on County Road 476. Alternatively, the Property can be accessed from the east through the adjacent Empire Mine. The Empire entrance gate is located on M-35, nine miles south of US Highway 41 between Marquette and Negaunee.

Michigan’s Upper Peninsula has a humid continental climate, typified by large seasonal temperature differences. Summers are generally warm and humid; winters are cold and long. Precipitation in the area averages approximately 31 in. of rain and 102 in. of snow in the winter. Snowfall in the region is greatly influenced by the “lake effect” due to proximity to the Great Lakes. Many towns in the Upper Peninsula have recorded annual snowfalls in excess of 350 in., and storms can quickly reach whiteout conditions and last for days.

The operation employs a total of 967 salaried and hourly employees (including LS&I railroad staff) as of Q4 2021. The majority of the employees live within a 50 mi radius of the Property. Marquette County has an estimated population of 66,000 people.

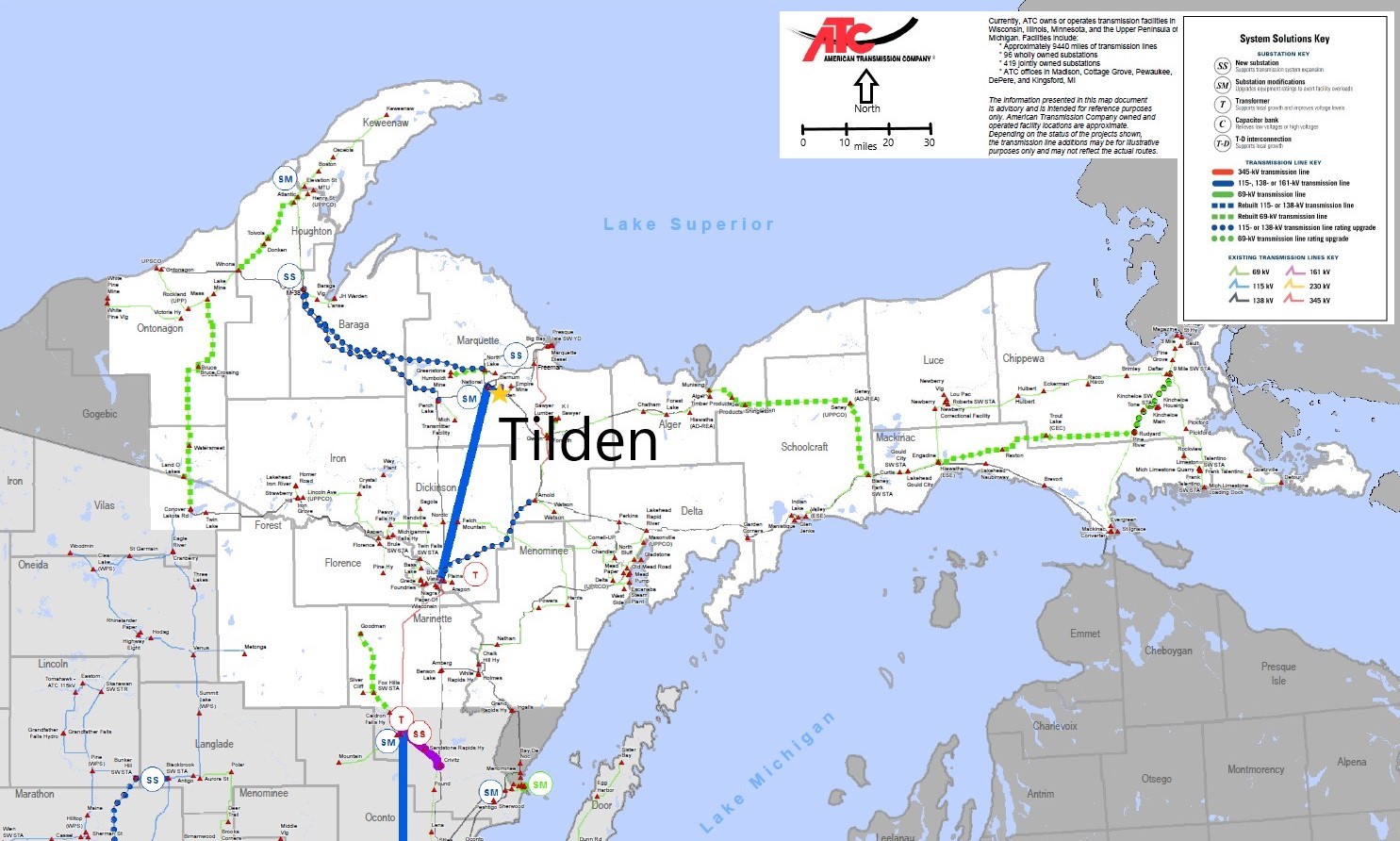

The Property is located in a historically important, iron-producing region in Northern Michigan. All infrastructure necessary to mine and process significant commercial quantities of iron ore exist at the current time. Infrastructure items include administration buildings and offices, maintenance shops, high-voltage electrical supplies, natural gas pipelines that connect into the North American distribution system, concentrating plant, pelletizing plant, water sources, paved roads and highways, railroads for transporting raw materials and final product, port facilities that connect into the Great Lakes and towns where employees live.

The Property is within the limits of a topographic region known as the Superior Uplands, a part of the Canadian Shield. The Property features elevations ranging from approximately 1300 to 1800 ft above sea level (fasl). Topography is hilly and is dominated by glacially influenced landforms. The Property is located in the Western Upper Peninsula Ecoregion (Section IX) and characterized by a landscape

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 7

featuring moraines, drumlins, lake plains, outwash channels, outwash plains, and glacially eroded bedrock ridges (Albert, 1995). Vegetation in the vicinity of Tilden is described as northern hardwood forest dominated by sugar maple, eastern hemlock, basswood, yellow birch, and sparse white pine.

1.3.3History

Iron deposits in Northern Michigan were originally described in the early 1840s by Douglass Houghton, Michigan’s first State Geologist. Exploration and mining of high-grade iron oxides began in the mid to late 1840s, including Cliffs’ predecessors Cleveland Iron Company and Iron Cliffs Company, which merged in 1891 to form the CCIC. Mining was mainly focused on underground, high-grade iron deposits through the end of the Second World War, when they were almost depleted.

Extensive development of beneficiation-grade, open pit mining began, and the first commercial agglomeration (pellet) plant in the Lake Superior region started operations in 1952. Agglomeration was a relatively new process that took the concentrate from lower-grade deposits and produced pelletized product containing approximately 65% Fe.

After years of favorable experimental testing for processing of fine-grained hematite ores, the Property commenced operations in 1974 under a partnership of Algoma Steel, Stelco, and CCIC. The Property has since been at least partially in the possession of a subsidiary of Cliffs. In 2001, Cliffs acquired Algoma Steel's 45% interest in Tilden L.C. In 2017, Cliffs became the sole owner of the Tilden L.C. entity.

1.3.4Geological Setting, Mineralization, and Deposit

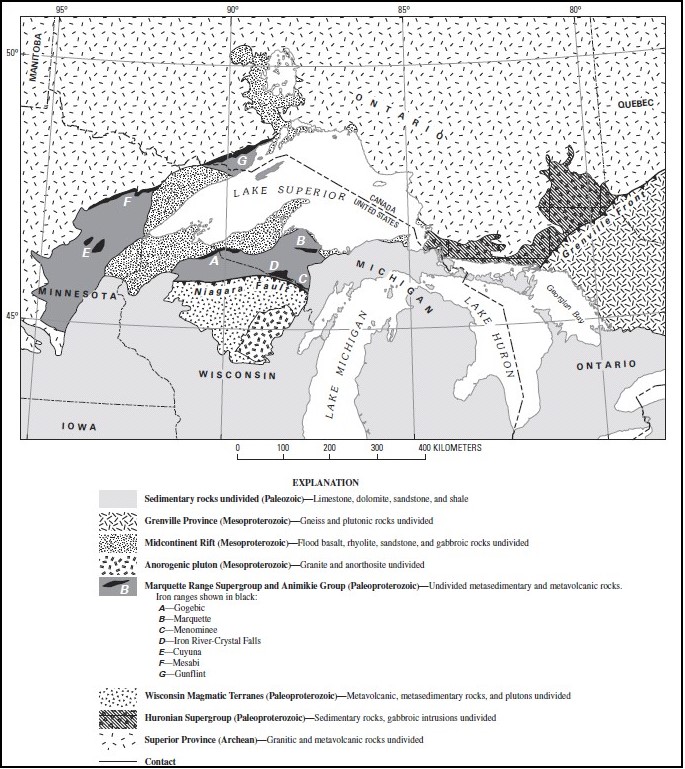

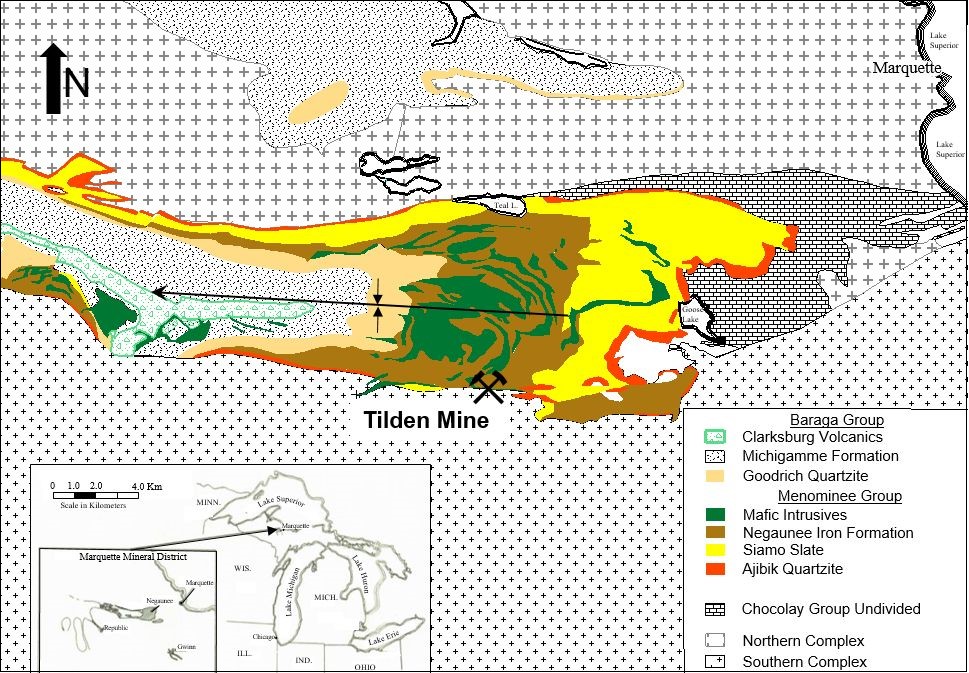

The Tilden deposit is a classic example of a banded iron formation (BIF) deposit of the Superior type and is located near the base of the Negaunee Iron Formation (Negaunee IF) of the Menominee Group, within the Marquette Range Super Group. The Negaunee IF and equivalents host most of the iron deposits in Michigan. It is Proterozoic in age and sits on the southern margin of the Marquette trough.

The deposit is modeled to extend from surface to up to 2,300 ft vertical depth below and is comprised of alternating layers of iron oxides and iron-poor chert in a northwest-plunging anticline; the axial surface dips steeply north, and the hinge line plunges 30° west-northwest down the center of the Main Pit. It is fault-bounded to the south by Archean gneiss terrane; the fault contact dips steeply north and aligns with the south wall of the Main Pit at Tilden. To the east of the Tilden deposit lies the Empire deposit (a stratigraphically deeper extension of the Tilden deposit) and its historical pit. Tilden is impacted by a higher frequency and volume of intrusions and sills northward, but is open to the west, at depth, and in some areas to the north.

The iron formation facies at Tilden were locally modified by clay-silica alteration associated with faulting and intrusions, as well as by varying degrees of oxidation throughout. Some BIF units in the south were disrupted by turbidite flows, typified by lensoidal inclusions of clastic material.

The Tilden Mine is unique among Cliffs-owned operations because the primary ore mineral at Tilden is hematite, with other minerals being martite (oxidized pseudomorph of magnetite), goethite, and siderite (iron carbonate mineral), as opposed to strictly magnetite. Tilden is also unique in the world in that the hematite-dominant ore is mined at a low grade, concentrated using a selective-flocculation desliming and flotation process, and pelletized. Although some now-expended areas at Tilden did mine and magnetically recover magnetite-dominant ore prior to 2009, remaining Mineral Resources at Tilden

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 8

are hematite-dominant. The adjacent (now indefinitely idled) Empire deposit hosted primarily magnetite ore, and unoxidized magnetite is variably present at Tilden.

1.3.5Exploration

Cliffs and Tilden Mine do not maintain detailed records or results of non-drilling prospecting methods used during initial exploration activities, such as geophysical surveys, mapping, trenching, and test pits, conducted prior to Cliffs’ development of the operation. No exploration work or investigations other than drilling and limited pit mapping have been conducted by Cliffs at Tilden.

The Tilden drill hole database consists of 382,605 ft of drill hole information in 578 drill holes, completed from the 1950s to 2020. Annual exploration drilling programs at Tilden have completed zero to 42 drill holes. Of the last 10 years, nine have included drill hole programs and have averaged 10 drill holes per year. Diamond, hammer, and churn drilling have all been employed at Tilden, with diamond drilling having been exclusively used since 2008.

1.3.6Mineral Resource Estimates

A geological model was constructed by SLR considering regional mapping, drill hole logging, and blast hole analytical results, in addition to grade control modeling and flotation ore coding. Data verification included standard database verification, a review of QA/QC protocols and results, and a comparison of blast hole and exploration drill hole results.

The Tilden Mineral Resource estimate was completed by SLR using a conventional block modeling approach, defining estimation domains from wireframes built in Seequent’s Leapfrog Geo (Leapfrog Geo) software and using a regular block model built and interpolated in Seequent’s Leapfrog Edge (Leapfrog Edge) software. The general workflow included the creation of a geological model from mapping, drill and blast hole logging, and sampling, which were used to define discrete domains of non-iron formation and iron formation sub-units. Iron formation drill hole samples were composited, and the estimation of six variables (crude iron and magnetic iron, wtrec, and iron, phosphorus, and silica in concentrate) was completed using ordinary kriging (OK) over five passes in iron formation units, the first of which incorporated blast hole samples. Distance restriction of outlier grades was applied to selected domains and variables. Blocks were classified as Indicated or Inferred using distance-based and qualitative criterion. Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves dated May 10, 2014 (CIM (2014) definitions) were used for Mineral Resource classification. Models were depleted to December 31, 2021. Estimates were validated using standard industry techniques and were peer reviewed prior to finalization.

A detailed breakdown of the Mineral Resources exclusive of Mineral Reserves is presented in Table 1-5. Mineral Resources were defined and constrained within an open-pit shell, prepared by Cliffs and based on a US$90/LT pellet price, and meet the following cut-off grade criteria, based on existing pellet specifications and price contracts:

•≥ 25% wtrec

•≥ 25% crude iron content (crudefe)

•≤ 0.07% phosphorus in concentrate (conphos)

•≤ 6% to 8.5% silica in concentrate (consio2) (domain dependent)

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 9

The pellet cost basis for the Lerchs-Grossmann (LG) optimization is based on a dry 61.5% Fe fluxed pellet.

Table 1-5: Summary of Tilden Mineral Resources - December 31, 2021

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | | | | | | | |

| Category | Long Tons

(MLT) | Crude Fe

(%) | Process Recovery

(%) | Wet Pellets

(MLT) |

| Measured | - | - | - | - |

| Indicated | 135.4 | 35.5 | 35.9 | 48.6 |

| Total Measured + Indicated | 135.4 | 35.5 | 35.9 | 48.6 |

| Inferred | 350.4 | 34.7 | 36.4 | 127.4 |

Notes:

1.Tonnage is reported in long tons equivalent to 2,240 lb.

2.Tonnage is reported exclusive of Mineral Reserves and has been rounded to the nearest 100,000.

3.Mineral Resources are estimated at cut-off grades of 25% crudefe, 25% wtrec, 0.07% conphos, and 6% consio2 to 8.5% consio2, domain dependent.

4.Mineral Resources are estimated using a pellet value of US$90/LT.

5.Pellets are reported as fluxed and wet, containing 61.5% Fe; shipped pellets contain 1.5% moisture.

6.Tonnage estimate based on estimated depletion from a surveyed topography on December 31, 2021.

7.Resources are crude ore tons as delivered to the primary crusher; pellets are as loaded onto rail cars.

8.Classification of Mineral Resources is in accordance with the S-K 1300 classification system.

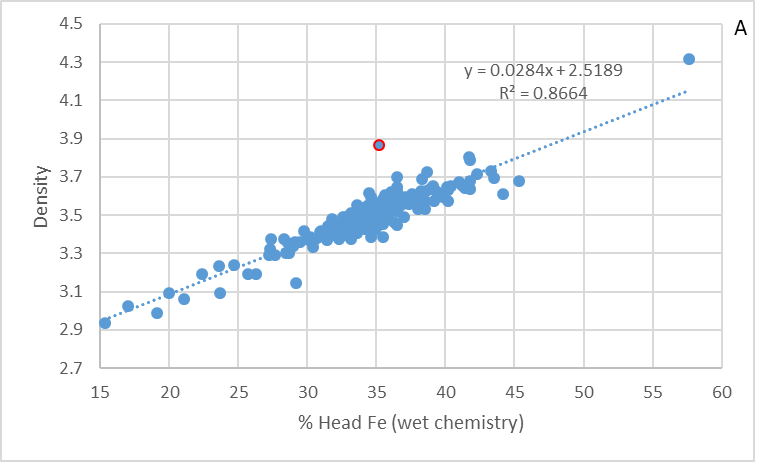

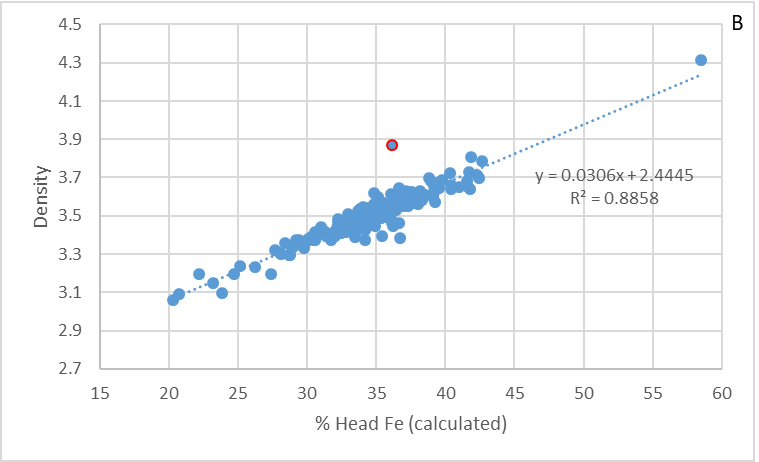

9.Bulk density is assigned based on a regression equation related to crude Fe.

10.Mineral Resources are 100% attributable to Cliffs.

11.Mineral Resources are constrained within an optimized pit shell.

12.Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

13.Numbers may not add due to rounding.

The Tilden operation is currently active and in full production. The SLR QP is of the opinion that with consideration of the recommendations summarized in this section, any issues relating to all relevant technical and economic factors likely to influence the prospect of economic extraction can be resolved with further work.

1.3.7Mineral Reserve Estimate

Mineral Reserves in this TRS are derived from the current Mineral Resources. The Mineral Reserves are reported as crude ore and are based on open pit mining. Crude ore is the unconcentrated ore as it leaves the Mine at its natural in situ moisture content. The Proven and Probable Mineral Reserves for Tilden are estimated as of December 31, 2021 and summarized in Table 1-6.

Table 1-6: Summary of Tilden Mineral Reserves - December 31, 2021

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | | | | | | | |

| Category | Crude Ore Mineral Reserves

(MLT) | Crude Ore Fe

(%) | Process Recovery (%) | Wet Pellets

(MLT) |

| Proven | 3.6 | 35.3 | 36.1 | 1.3 |

| Probable | 516.4 | 34.7 | 37.0 | 191.1 |

| Proven & Probable | 520.0 | 34.7 | 37.0 | 192.4 |

Notes:

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 10

1.Tonnage is reported in long tons equivalent to 2,240 lb and has been rounded to the nearest 100,000.

2.Mineral Reserves are reported at a $90/LT wet hemflux pellet price freight-on-board (FOB) Lake Superior, based on the three-year trailing average of the realized product revenue rate.

3.Mineral Reserves are estimated at a crude ore cut-off grade of 25.0% Fe along with additional metallurgical constraints.

4.Mineral Reserves include mining dilution built into the Mineral Resource model and mining extraction losses by geometallurgical domain, which range from 4% to 30%.

5.The Mineral Reserve mining stripping ratio (waste units to crude ore units) is at 1.2.

6.Proven Mineral Reserves are crude ore that has been mined and stockpiled for processing during the LOM.

7.Process recovery is reported as the percent mass recovery to produce a wet hemflux pellet containing 61.5% Fe; shipped hemflux pellets average approximately 1.5% moisture.

8.Tonnage estimate is based on the end of year, December 31, 2021 topographic survey.

9.Mineral Reserve tons are as delivered to the primary crusher; wet hemflux pellets are as loaded onto lake freighters at Marquette, Michigan.

10.Classification of Mineral Reserves is in accordance with the S-K 1300 classification system.

11.Mineral Reserves are 100% attributable to Cliffs.

12.Numbers may not add due to rounding.

The pellet price used to perform the evaluation of the Mineral Reserves in the current mining model is US$90/LT wet hemflux pellet. This price is consistent with the Mineral Reserve price used at Cliffs’ Northshore and UTAC operations and is supported by the current three-year trailing average of the realized product revenue rate of US$98/LT wet hemflux pellet. Proven Mineral Reserves consist exclusively of crude ore that has been mined and stockpiled for future processing in the LOM plan. The costs used in this study represent all mining, processing, transportation, and administrative costs including the loading of pellets into lake freighters at Marquette, Michigan.

SLR is not aware of any risk factors associated with, or changes to, any aspects of the modifying factors such as mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the Mineral Reserve estimate.

1.3.8Mining Methods

The Tilden deposit is mined using conventional surface mining methods. The surface operations include:

•Overburden (glacial till) removal

•Drilling and blasting (excluding overburden)

•Loading and haulage

•Crushing and rail loading

The Mineral Reserve is based on the ongoing annual crude ore production of 20 MLT to 22 MLT producing approximately 7.7 MLT of wet hemflux pellets for domestic consumption.

Mining and processing operations are scheduled 24 hours per day, and the mine production is scheduled to directly feed the processing operations.

The current LOM plan has mining scheduled for 25 years and mines the known Mineral Reserve. The average stripping ratio is approximately 1.2 waste units to 1 crude ore unit (1.2 stripping ratio).

The final Tilden pit is a single pit approximately 2.5 mi along strike, up to 0.9 mi wide, and up to 1,980 ft deep.

The Mine’s operation has a strict crude ore blending requirement to ensure the Plant receives a consistent crude ore feed. The most important characteristics of the crude ore are the crude ore iron grade and the predicted concentrate mass recovery and concentrate iron, silica, and phosphorus content. Operationally, blending is done on a shift-by-shift basis. Generally, three to four crude ore

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 11

loading points are mined at one time with dispatch operators issuing real-time adjustments to meet specified crude ore blends for the Plant.

Crude ore is hauled to the crushing facility and either direct tipped to the primary crusher or stockpiled. Haul trucks are alternated to blend delivery from the multiple crude ore loading points. The crude ore stockpiles are used as an additional source for blending and production efficiency. Crushed crude ore is conveyed to a covered storage building for stockpiling prior to being fed to the concentrator. Waste rock and overburden are hauled to one of the many waste stockpiles peripheral to the pit or to the in-pit backfill.

The major pieces of pit equipment include electric drills, electric rope shovels, haul trucks, front-end loaders (FELs), bulldozers, and graders. Extensive maintenance facilities are available at the mine site to service the mine equipment.

1.3.9Processing and Recovery Methods

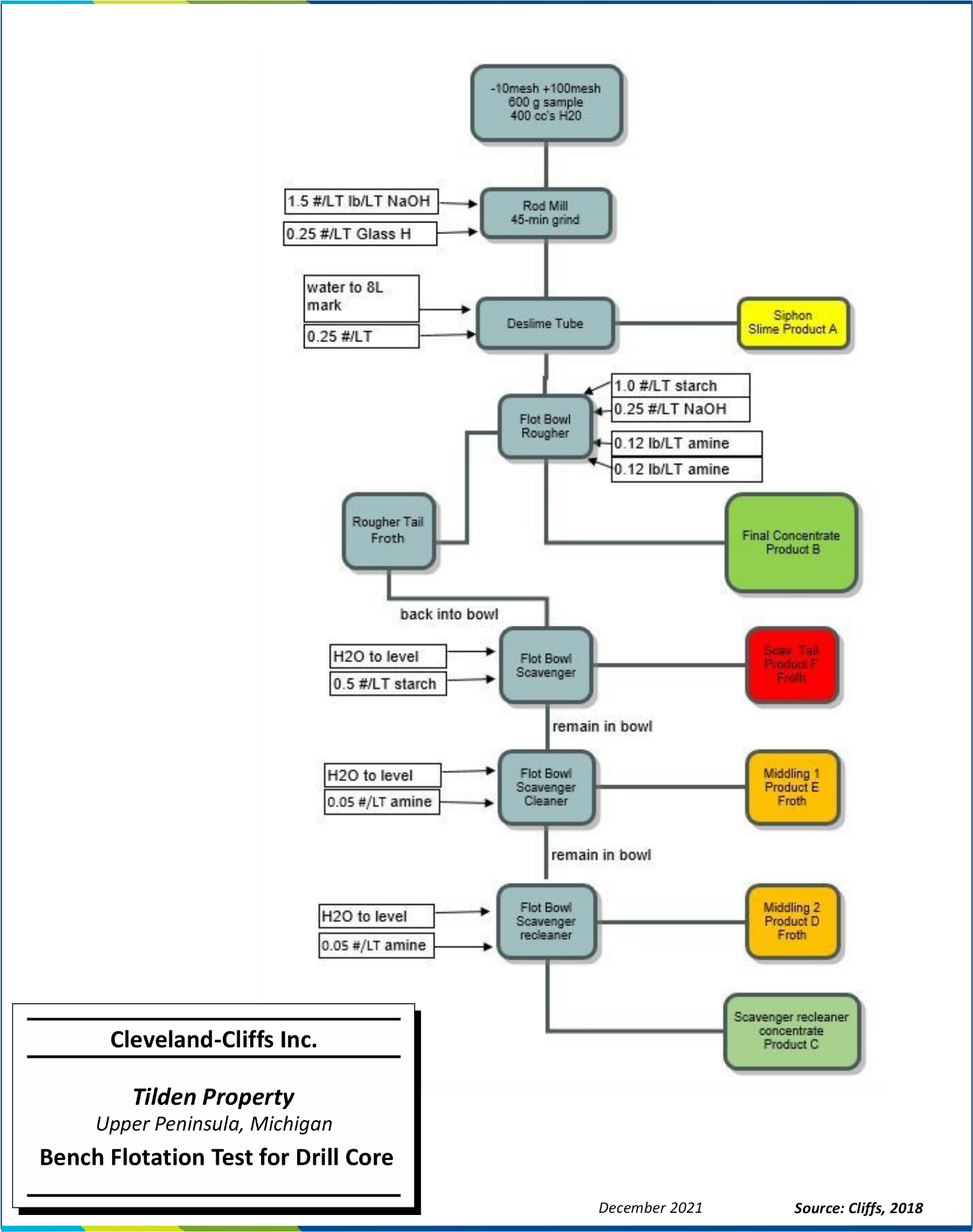

The mix of magnetite and primarily hematite ores at Tilden is unique to US iron ore mines. Typical flowsheets developed for beneficiation-grade magnetite ores of the Lake Superior region were not applicable, as most of the iron oxide occurs as non-magnetic hematite, which requires fine grinding for liberation. Metallurgical research conducted in the 1960s focused on creating a process that included selective flocculation and desliming followed by cationic silica (SiO2) flotation.

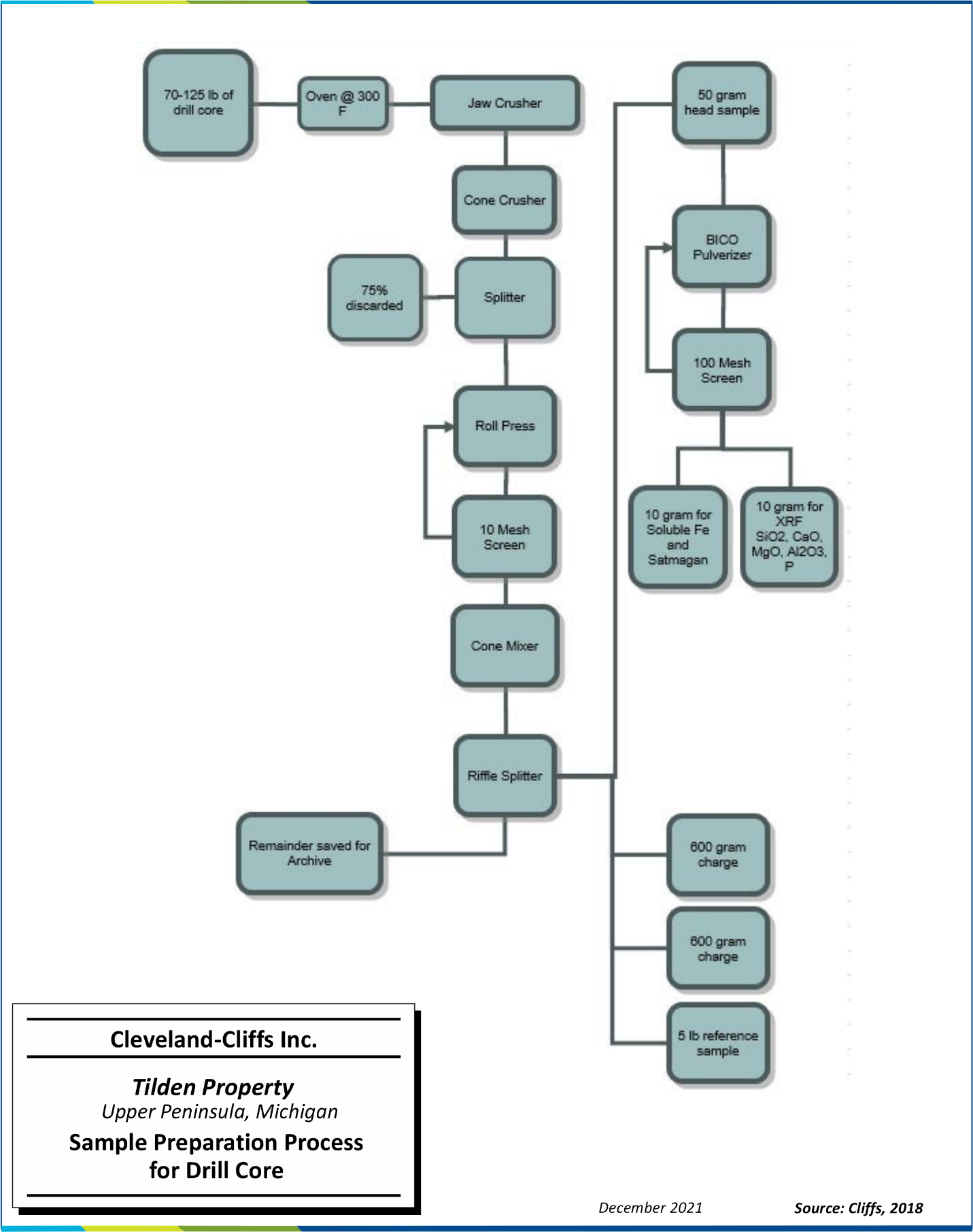

A standardized bench-scale flotation test was designed to simulate the Tilden hematite grinding and concentrating circuit. Results from the standardized bench flotation test are used to characterize rock samples as either crude iron ore or waste rock. The data are used to build a resource model and mine plan to supply a consistent blend of ore to the concentrator. Deleterious materials impacting economic extraction are observed in the flotation bench test, which may include clay minerals, quartz inclusions within iron oxide bands, fine goethite, and carbonates.

The capacity of the Tilden concentrator and pellet plant is 7.7 MLT/y of fluxed pellets from both hematite and magnetite crude ore sources. The Plant includes primary crushing, autogenous primary and secondary grinding, selective flocculation and desliming, flotation, filtration, drying, balling (agglomeration), and induration. The concentrator is designed to campaign either hematite ores or magnetite ores but not in combination.

The processing of magnetite-dominant ores at the Tilden concentrator ceased in 2009. Magnetite ore from the Tilden was delivered and processed at the Empire Mine from 2010 through 2016 when the Empire was indefinitely idled. Remaining Mineral Resources and Mineral Reserves at Tilden are processed in hematite-based flotation circuits.

Mined ore is directly dumped from haul trucks into a gyratory crusher to produce a nominal nine-inch crushed product, which is conveyed to the ore storage building ahead of the grinding circuit. Primary grinding is accomplished with eleven primary AG mills, each driven by two, 2,860 hp synchronous motors. Each primary AG mill discharges to a triple-deck screen, producing coarse pebble for pebble mill grinding media, an intermediate product that is recycled to the AG mill, and a 100% passing 2 mm product that feeds the pebble mills. The pebble mills are operated in closed circuit with cyclones to produce a final grind of 80% to 85% passing 25 microns. Caustic soda and slaked lime are added to the water circuit to control pH prior to desliming and flotation.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 12

Starch and a dispersant are added to the slurry to selectively flocculate and depress the iron oxides while dispersing the fine silica gangue in advance of the deslime thickeners. The deslime thickener overflow, containing the waste products, is fed to the tailings thickeners, and the deslime thickener underflow is conditioned with additional starch and advanced to the flotation circuit.

The reverse flotation circuit is divided into twelve lines, which float silica from the iron minerals with an amine collector. The rougher flotation concentrate represents final upgraded iron concentrate and is advanced to the concentrate thickener. The rougher tail is scavenged in four flotation stages to remove entrained iron values. The scavenger flotation concentrates are recycled to the rougher feed, and scavenger tails are pumped to the tailings thickeners.

The iron concentrate is thickened to approximately 65% to 70% solids in the concentrate thickeners, neutralized to a pH of 7.0 using carbon dioxide, and then filtered in a series of vacuum disc filters to approximately 11.5% weight by weight (w/w) moisture content. Filtered concentrates are either sent directly to the pelletizing plant, a thermal drying circuit, or to a concentrate storage stockpile.

Fluxstone consisting of dolomite and calcite is delivered to site via truck and stored in stockpiles. The material is fed from a stockpile via apron feeders and processed in two, 15.5 ft-diameter x 30 ft-long ball mills. The fluxstone slurry is added to the iron concentrate prior to filtering to ensure homogenous mixing.

The unit processes of the pelletizing plant include concentrate drying, agglomeration or balling, sizing, and induration in a grate kiln and cooler to produce final pellets, and pellet storage and loadout.

Concentrate is conveyed from filtration or the concentrate stockpile to the balling section of the pelletizing plant. A portion of the concentrate is dried in a rotary dryer and then recombined with the concentrate feed to achieve 9.5% w/w moisture for balling. Green balls are produced in fourteen rotating balling drums operating in parallel. Bentonite clay binder is added to the balling drum feed, and green balls are discharged onto a vibrating seed screen with a two-feet-long grizzly extension for oversize removal. The screen undersize is returned to the balling drum, and the grizzly oversize is returned to the concentrate bin or diverted to outdoor storage. The seed screen product is conveyed by a reciprocating conveyor, which distributes the green balls over a grate feed belt.

The green balls enter a moving grate, which passes through 3.5 bays of updraft drying, 7.5 bays of downdraft drying, and eight bays of downdraft pre-heating and are then discharged into one of two rotary kilns. Heat for the kilns is produced with a combination of pulverized coal and/or natural gas. Product from the kiln is discharged into two rotary coolers, sufficiently cooling the pellets to be transported by conveyor.

Cooled pellets are conveyed directly to either a railroad load-out bin or to an outdoor stockpile with nominal capacity of 2 MLT. Pellets are loaded into rail cars and transported to the dock facility in Marquette, Michigan or shipped directly to customers by rail. Pellet stockpiles are screened to reduce fines using loaders feeding a portable screening plant. Pellet chips and fines from this process are sold as a secondary product.

1.3.10Infrastructure

The Property is in a historically important, iron-producing region in the Upper Peninsula of Northern Michigan. All the infrastructure necessary to mine and process commercial quantities of iron ore is in place.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 13

Infrastructure items include:

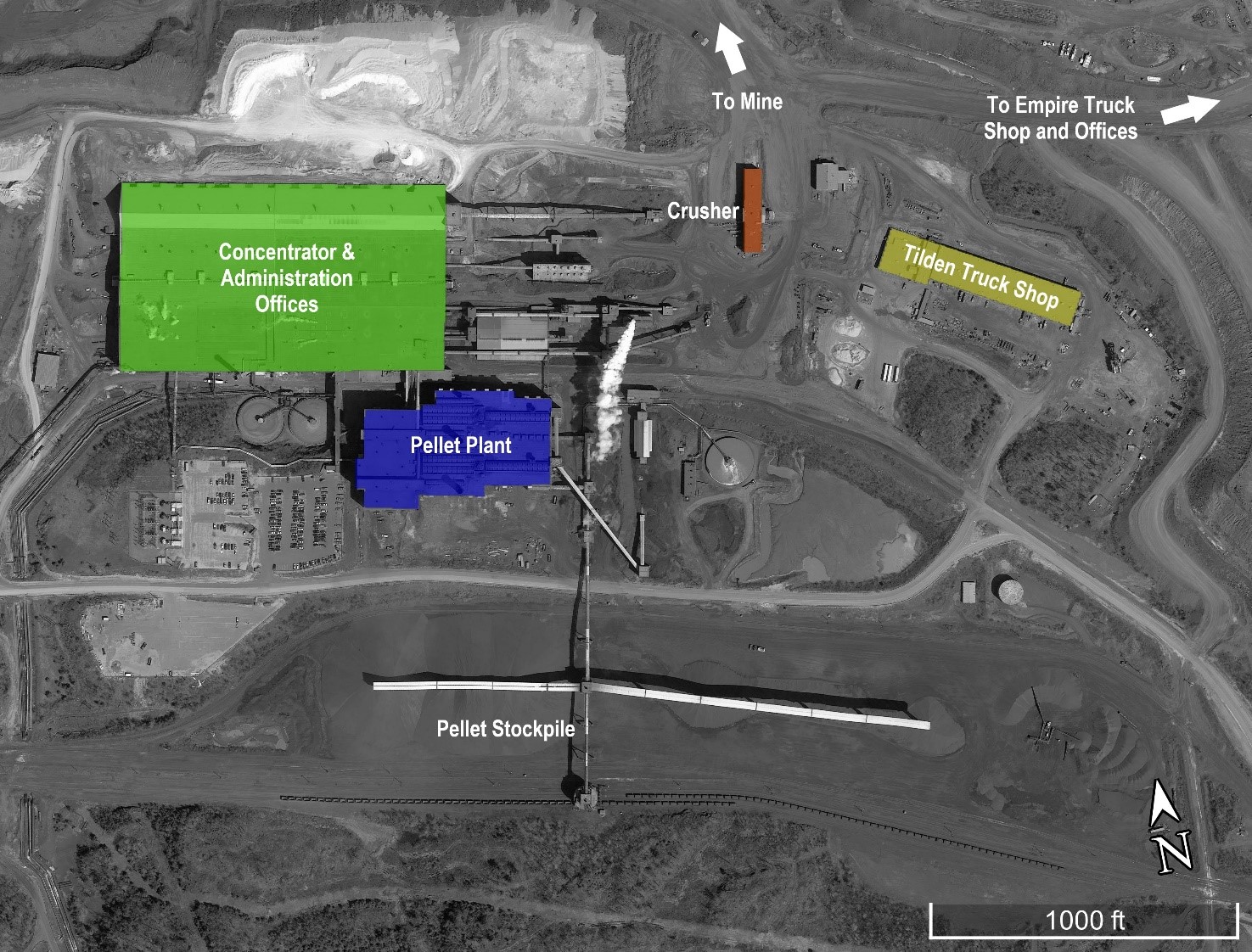

•The Mine, concentrator, and concentrate pelletizing facilities near Marquette, Michigan.

•The main processing facility is contained in a conventional, multi-level, insulated steel building. Mining offices and mobile equipment maintenance shops are separated from the main facility and are located on the Empire Mine property.

•Power is supplied by Upper Michigan Energy Resources (UMERC) that supplies power through the existing power grid, which is interconnected to neighboring states and is received at its substation on transmission lines owned by American Transmission Company.

•Backup diesel-powered generators are installed at several locations to operate critical equipment should main power be lost.

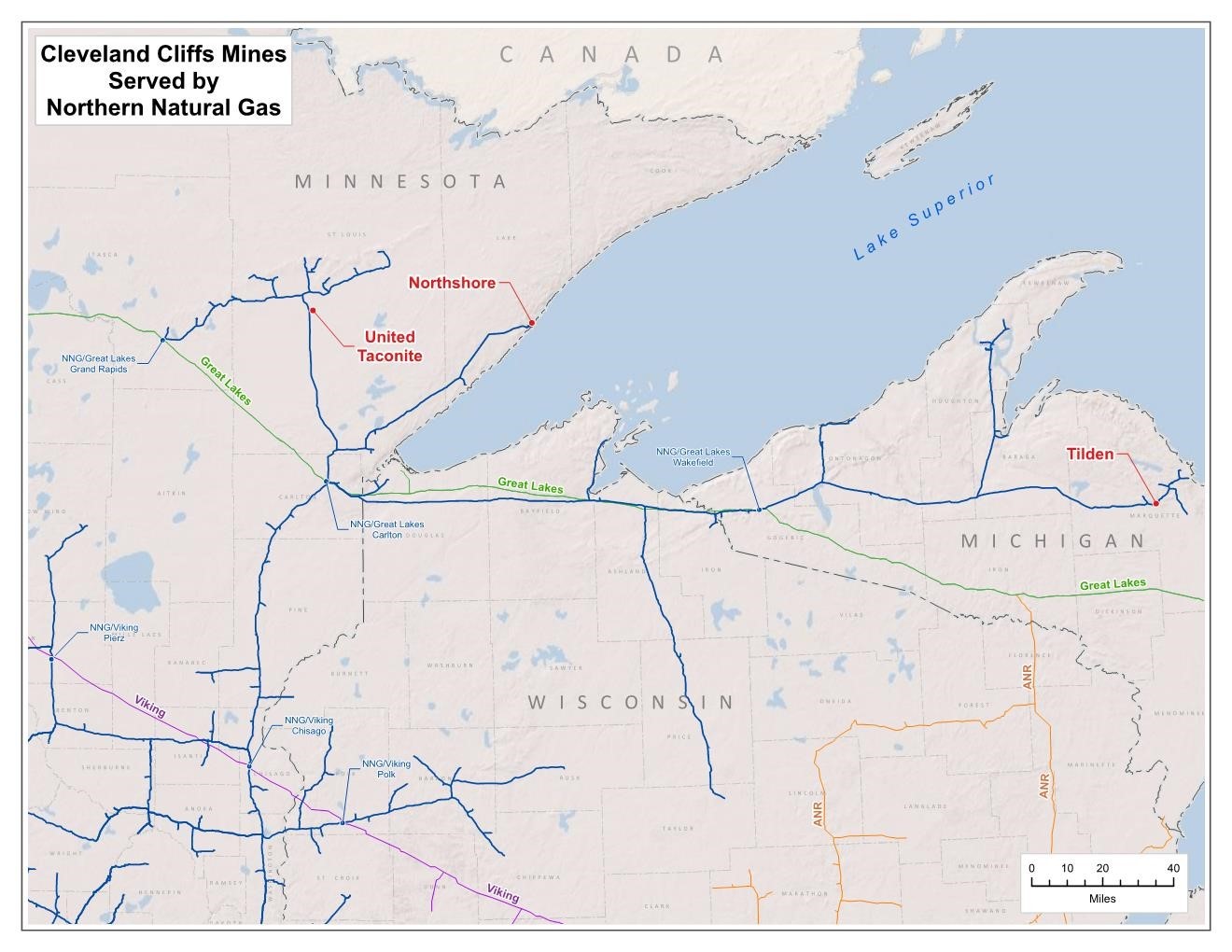

•Natural gas is primarily used for firing the rotary kilns at the pelletizing plant and water boilers in the concentrator. Natural gas is purchased from Encore Energy and supplied to the site via a gas pipeline owned and operated by Northern Natural Gas (NNG), which has an extensive interstate pipeline system.

•The Tilden pellet plant kilns are a dual fuel system with the ability to operate on pulverized coal, natural gas, or a combination of both.

•U.S. Oil supplies the Tilden Mine from its terminal in Green Bay, Wisconsin. The Mine has one 20,000 gal, above-ground diesel fuel tank and one 10,000 gal, underground gasoline storage tank.

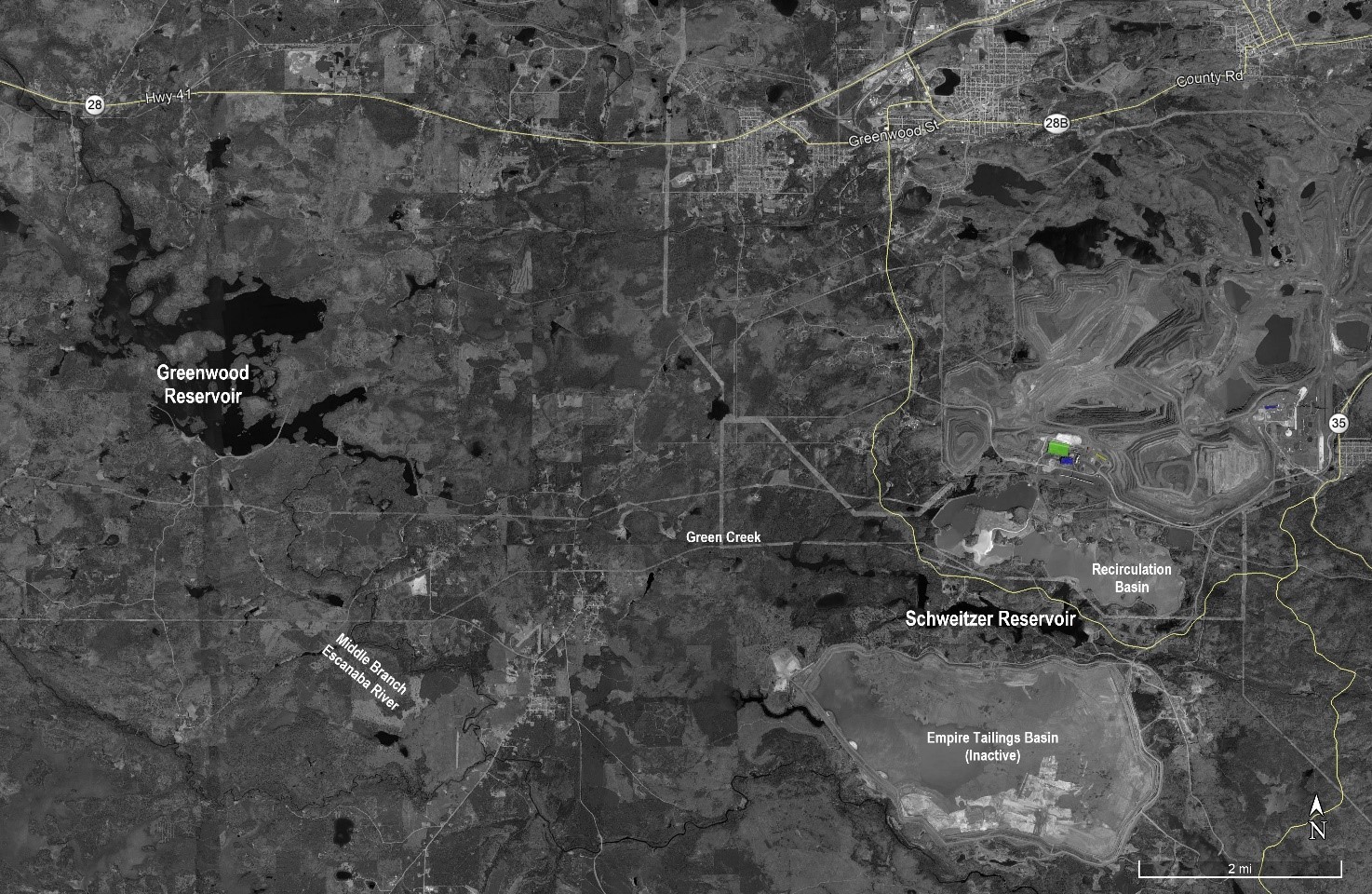

•Fresh make-up water for the process is supplied from the Greenwood Reservoir, which is located approximately seven miles southwest of Ishpeming and is on the Middle Branch Escanaba River.

•Process water is primarily supplied by tailings reclaim.

•Potable water is supplied by two deep well pumps located on site.

•Paved roads and highways.

•Pellets produced at the site are shipped in rail cars by the Lake Superior & Ishpeming Railroad (LS&I), a wholly owned subsidiary of Cliffs, 22 mi to the LS&I dock in Marquette, Michigan.

•Tailings are stored in the GTB located approximately five miles southeast of the Tilden concentrator plant and nine miles from Lake Superior. The GTB is comprised of two ring dike-type impoundments: the GNTB, which encompasses approximately 1,350 acres, and the GSTB, which encompasses approximately 1,100 acres.

•Dock facilities in Marquette include 50,000 LT of pellet storage and ship loaders for loading 60,000 LT-capacity lakers that transport pellets to steel mills on the Great Lakes.

•Pellets can also be shipped using the Canadian National (CN) railroad. The CN owns and operates its own rail fleet. Currently, one customer receives direct rail deliveries by CN to Sault Ste. Marie, Ontario, Canada, a distance of 120 mi from the Property.

•Accommodations for employees.

•Local and State infrastructure also includes hospitals, schools, airports, equipment suppliers, fuel suppliers, commercial laboratories, and communication systems.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 14

1.3.11Market Studies

Cliffs is the largest producer of iron ore pellets in North America. It is also the largest flat-rolled steel producer in North America. In 2020, Cliffs acquired two major steelmakers, ArcelorMittal USA (AMUSA), and AK Steel (AK), vertically integrating its legacy iron ore business with steel production and emphasis on the automotive end market.

Cliffs owns or co-owns five active iron ore mines in Minnesota and Michigan. Through the two acquisitions and transformation into a vertically integrated business, the iron ore mines are primarily now a critical source of feedstock for Cliffs’ downstream primary steelmaking operations. Based on its ownership in these mines, Cliffs’ share of annual rated iron ore production capacity is approximately 28.0 million LT, enough to supply its steelmaking operations and not have to rely on outside supply.

The importance of the steel industry in North America and specifically the USA is apparent by the actions of the US federal government in implementing and keeping import restrictions in place. It is important for middle-class job generation and the efficiency of the national supply chain. It is also an industry that supports the country’s national security by providing products used for US military forces and national infrastructure. Cliffs expects the US government to continue recognizing the importance of this industry and does not see major declines in the production of steel in North America.

Tilden L.C. ships flux pellets annually to Cliffs’ steelmaking facilities in the Midwestern USA, with some quantities shipped by rail to external customers.

For cash flow projections, Cliffs uses a blended pellet revenue rate of $98/WLT Free on Board (FOB) Mine based on a three-year trailing average for 2017 to 2019. Based on macroeconomic trends, SLR is of the opinion that Cliffs’ pellet prices will remain at least at the current three-year trailing average of $98/WLT or above for the next five years.

1.3.12Environmental Studies, Permitting and Plans, Negotiations, or Agreements with Local Individuals or Groups

Tilden L.C. indicated that it presently has the requisite operating permits for the Mine and Plant and estimates that the mine life will be 25 years. Environmental monitoring during operations includes water and air quality monitoring. Closure plans and other post-mining plans are required to be prepared within two years of anticipated closure. Cliffs indicated that it conducts an in-depth review every three years to ensure that the Asset Retirement Obligation (ARO) legal liabilities are accurately estimated based on current laws, regulations, facility conditions, and cost to perform services. These cost estimates are conducted in accordance with the Financial Accounting Standards Board (FASB) Accounting Standards Codification (ASC) 410. SLR is not aware of any formal commitments to local procurement and hiring; however, Cliffs indicated that it has a long-standing relationship with local vendors.

1.3.13Capital and Operating Cost Estimates

Productive and sustaining capital expenditure estimates for the remaining life of the operation are presented in Table 1-7. The LOM capital cost forecast is shown for the next five-year period from 2022 to 2026, which totals $314.2 million and an additional $579.9 million from 2027 to the last year of mining in 2046. Total capital expenditures are estimated at $894.2 million.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 15

Table 1-7: LOM Capital Costs

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | | | | | | | | | | | | | | | | | | | |

| Type | Values | Total | 2022 | 2023 | 2024 | 2025 | 2026 | 2027-2046 |

| Total | $ millions | 894.2 | 63.5 | 82.9 | 45.7 | 43.8 | 78.3 | 579.9 |

Operating costs are based on a full run rate of flux pellets consistent with what is expected for the life of the mine. A LOM average operating cost of $66.00/WLT pellet is estimated over the remaining 25 years of the mine life and is presented by area in Table 1-8.

Table 1-8: LOM Operating Costs

Cleveland-Cliffs Inc. – Tilden Property

| | | | | |

| Description | LOM

($/WLT Pellet) |

| Mining | 15.30 |

| Processing | 42.79 |

| Site Administration | 2.84 |

| General/Other | 5.07 |

| Operating Cash Cost | 66.00 |

Cliffs’ capital and operating costs estimates are derived from annual budgets and historical actuals over the long life of the current operation. According to the American Association of Cost Engineers (AACE) International, these estimates would be classified as Class 1 with an accuracy range of -3% to -10% to +3% to +15%.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 16

2.0INTRODUCTION

SLR International Corporation (SLR) was retained by Cleveland-Cliffs Inc. (Cliffs) to prepare an independent Technical Report Summary (TRS) for the Tilden Property (Tilden or the Property), located in Northern Michigan, USA. The owner of the Property, Tilden Mining Company L.C. (Tilden L.C.), is a wholly owned subsidiary of Cliffs.

The purpose of this TRS is to disclose year end (YE) 2021 Mineral Resource and Mineral Reserve estimates for Tilden.

Cliffs is listed on the New York Stock Exchange (NYSE) and currently reports Mineral Reserves of pelletized ore in SEC filings. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary.

The Property includes the Tilden Mine (the Mine) and processing facility (the Plant) located approximately five miles south of the city of Ishpeming, Michigan. The Property is also immediately west of Cliffs’ Empire Property, which was indefinitely idled in 2016. The Mine is a large, operating, open-pit iron mine and is unique among Cliffs’ US-owned operations because the primary ore mineral at Tilden is hematite, with other minerals being martite (oxidized pseudomorph of magnetite), goethite, and siderite (iron carbonate mineral), as opposed to strictly magnetite. The Property is also unique in the world in that the hematite-dominant ore is mined at a low grade, concentrated using a selective-flocculation desliming and flotation process, and pelletized.

The Property commenced operations in 1974 under a partnership of Algoma Steel, Stelco, J&L Steel, Wheeling-Pittsburgh Steel, Sharon Steel, and The Cleveland-Cliffs Iron Company (CCIC). The property has since been at least partially in the possession of a subsidiary of Cliffs. In 2001, Cliffs acquired Algoma Steel's 45% interest in Tilden L.C. In 2017, Cliffs became the sole owner of Tilden L.C.

The open-pit operation has a mining rate of approximately 21 million long tons (MLT) of ore per year and produces 7.7 MLT of iron ore pellets per year, which are mostly shipped by freighter via the Great Lakes to Cliffs’ steel mill facilities in the Midwestern USA, with some quantities shipped by rail to external customers.

2.1Site Visits

SLR Qualified Persons (QPs) visited the Property on October 24, 2019 and January 20 to 24, 2020. During the 2019 site visit, the SLR team all toured the tailings basin, plant laboratory, concentrator and pelletizing facilities plus rail pellet loadout site, and the mine offices and operational areas.

During the 2020 site visit, the SLR geologist visited the mine offices and worked with the mine geologists to update the geological and Mineral Resource block model.

2.2Sources of Information

Technical documents and reports on the Property were obtained from Cliffs’ personnel. During the preparation of this TRS, discussions were held with personnel from Cliffs:

•Kurt Gitzlaff, Director - Mine Engineering, Cliffs Technical Group (CTG)

•Michael Orobona, Principal Geologist, CTG

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 17

•Michael Koop, Lead Mine Engineer, CTG

•Scott Gischia, Director - Environmental Compliance

•Dean Korri, Director - Basin & Civil Engineering

•Sandy Karnowski, District Manager - Public Affairs

•John Elton, Senior Director - Corporate Accounting & Assistant Controller

•Tushar Mondhe, Senior Manager – Operations and Capital Finance

•Al Strandlie, Mine Geologist

•Tyson Murphy, Section Manager - Mine Engineering

•Todd Davis, Area Manager – Plant

•Kris Scherer, Tailings Engineer

•Brent Ketzenberger, Environmental Manager

This TRS was prepared by SLR QPs. The documentation reviewed, and other sources of information, are listed at the end of this TRS in Section 24.0, References.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 18

2.3List of Abbreviations

The U.S. System for weights and units has been used throughout this report. Tons are reported in long tons (LT) of 2,240 lb unless otherwise noted. All currency in this report is US dollars (US$ or $) unless otherwise noted. Abbreviations and acronyms used in this TRS are listed below.

| | | | | | | | | | | |

| Unit Abbreviation | Definition | Unit Abbreviation | Definition |

| a | annum | LT/h | long tons per hour |

| A | ampere | µL | microliter |

| acfm | actual cubic feet per minute | M | mega (million); molar |

| bbl | barrels | Ma | one million years |

| Btu | British thermal units | MBtu | thousand British thermal units |

| d | day | MCF | million cubic feet |

°F | degree Fahrenheit | MCF/h | million cubic feet per hour |

| fasl | feet above sea level | mi | mile |

| ft | foot | min | minute |

ft2 | square foot | MLT/y | million long tons per year |

ft3 | cubic foot | MPa | megapascal |

| ft/s | foot per second | mph | miles per hour |

| g | gram | MVA | megavolt-amperes |

| G | giga (billion) | MW | megawatt |

| Ga | one billion years | MWh | megawatt-hour |

| gal | gallon | MWLT | million wet long tons |

| gal/d | gallon per day | oz | Troy ounce (31.1035g) |

| g/L | gram per liter | oz/ton | ounce per short ton |

| g/y | gallon per year | ppb | part per billion |

| gpm | gallons per minute | ppm | part per million |

| hp | horsepower | psia | pound per square inch absolute |

| h | hour | psig | pound per square inch gauge |

| Hz | hertz | rpm | revolutions per minute |

| in. | inch | RL | relative elevation |

in2 | square inch | s | second |

| J | joule | ton | short ton |

| kLT | thousand long tons | stpa | short ton per year |

| k | kilo (thousand) | stpd | short ton per day |

kg/m3 | Kilogram per cubic meter | t | metric tonne |

| kVA | kilovolt-amperes | US$ | United States dollar |

| kW | kilowatt | V | volt |

| kWh | kilowatt-hour | W | watt |

| kWLT | thousand wet long tons | wt% | weight percent |

| L | liter | WLT | wet long ton |

| lb | pound | w/w | weight by weight |

| LT | long or gross ton equivalent to 2,240 pounds | y | year |

| LT/d | long tons per day | yd3 | cubic yard |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 19

| | | | | |

| Acronym | Definition |

| AACE | American Association of Cost Engineers |

| AK | AK Steel |

| AMUSA | ArcelorMittal USA |

| ANSI | American National Standards Institute |

| ARO | asset retirement obligation |

| ASC | Accounting Standards Codification |

| ASQ | American Society for Quality |

| ASTM | American Society for Testing and Materials |

| BF | blast furnace |

| BFA | bench face angle |

| BH | bench height |

| BIF | banded iron formation |

| BLS | United States Bureau of Labor Statistics |

| CCD | counter-current decantation |

| CCIC | Cleveland-Cliffs Iron Company |

| CCP | Conceptual Closure Plan |

| CERCLA | Comprehensive Environmental Response, Compensation, and Liability Act |

| CFR | Cost and Freight |

| CN | Canadian National Railroad |

| COA | certificates of analysis |

| CRIRSCO | Committee for Mineral Reserves International Reporting Standards |

| D&A | depreciation and amortization |

| DDH | diamond drill hole |

| DMO | Department Maintenance Office |

| DOSS | Dioctyl Sulfosuccinate |

| DRI | direct reduced iron |

| DSO | direct-shipping iron ore |

| EAF | electric arc furnace |

| EAP | Emergency Action Plan |

| EGLE | Michigan Department of Environment, Great Lakes and Energy |

| EIS | Environmental Impact Statement |

| EMP | Environmental Management Plan |

| EMS | environmental management system |

| EPA | United States Environmental Protection Agency |

| ESOP | Environmental Standard Operating Procedures |

| EOR | Engineer of Record |

| FASB | Financial Accounting Standards Board |

| FDCP | Fugitive Dust Control Plan |

| FOB | Free on Board |

| GHG | greenhouse gas |

| GIM | Geoscientific Information Management |

| GNTB | Gribben North Tailings Basin |

| GPS | global positioning system |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 20

| | | | | |

| Acronym | Definition |

| GSI | Geological Strength Index |

| GSSI | General Security Services Corporation |

| GSTB | Gribben South Tailings Basin |

| GTB | Gribben Tailings Basin |

| HBI | hot briquetted iron |

| HRC | hot-rolled coil |

ID2 | Inverse distance squared |

ID3 | Inverse distance cubed |

| IF | iron formation |

| IRA | Inter-ramp angle |

| IRR | internal rate of return |

| ISO | International Standards Organization |

| KEV | key economic variables |

| LG | Lerchs-Grossmann |

| LiDAR | light imaging, detection, and ranging |

| LMF | Laurentian Mixed Forest |

| LOM | life of mine |

| LS&I | Lake Superior & Ishpeming Railroad |

| MAC | Mining Association of Canada |

| MLT | million long tons |

| MR | moving range |

| MRCC | Midwestern Regional Climate Center |

| NAAQS | National Ambient Air Quality Standards |

| NAD | North American Datum |

| NESHAP | National Emission Standards for Hazardous Air Pollutants |

| NGO | non-governmental organization |

| NN | nearest neighbor |

| NNG | Northern Natural Gas |

| NOAA | National Oceanic and Atmospheric Administration |

| NOLA | Nuclear On-Line Analyzer |

| NPDES | National Pollution Discharge Elimination System |

| NPV | net present value |

| OMS | Operations, Maintenance, and Surveillance |

| OSA | overall slope angle |

| QA/QC | quality assurance/quality control |

| QP | Qualified Person |

| RC | rotary circulation drilling |

| RCRA | Resource Conservation and Recovery Act |

| ROM | run of mine |

| RQD | rock quality designation |

| RTR | risk and technology review |

| SDS | State Disposal System Permit |

| SEC | United States Securities and Exchange Commission |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 21

| | | | | |

| Acronym | Definition |

| SG | specific gravity |

| SMU | selective mining unit |

| SQL | Structured Query Language |

| SPC | Statistical Process Control |

| SPT | standard penetration testing |

| TMDL | total maximum daily load |

| TRS | Technical Report Summary |

| TSF | tailings storage facility |

| TSP | total suspended particulates |

| UCS | uniaxial compressive strength |

| UMERC | Upper Michigan Energy Resources |

| USGAAP | United States General Accepted Accounting Principles |

| USGS | United States Geological Survey |

| USNRC | United States Nuclear Regulatory Commission |

| WTF | water treatment facility |

| XRF | x-ray fluorescence |

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 22

3.0PROPERTY DESCRIPTION

3.1Property Location

The Property is located in Marquette County, in Michigan’s Upper Peninsula, USA, on the Marquette Iron Range, approximately five miles south of the city of Ishpeming at latitude 46° 27' N and longitude 87° 39' W. The Property is also immediately adjacent to Cliffs’ indefinitely idled Empire Mine and processing facility. Figure 3-1 shows the location of the Property.

3.2Land Tenure

3.2.1Mineral Titles

Land ownership and mineral leases are held by Tilden L.C., which is a wholly owned subsidiary of Cliffs. Initial acquisitions from outside parties were accomplished by CCIC over 150 years ago and moved to the various partnerships before Tilden L.C. was established.

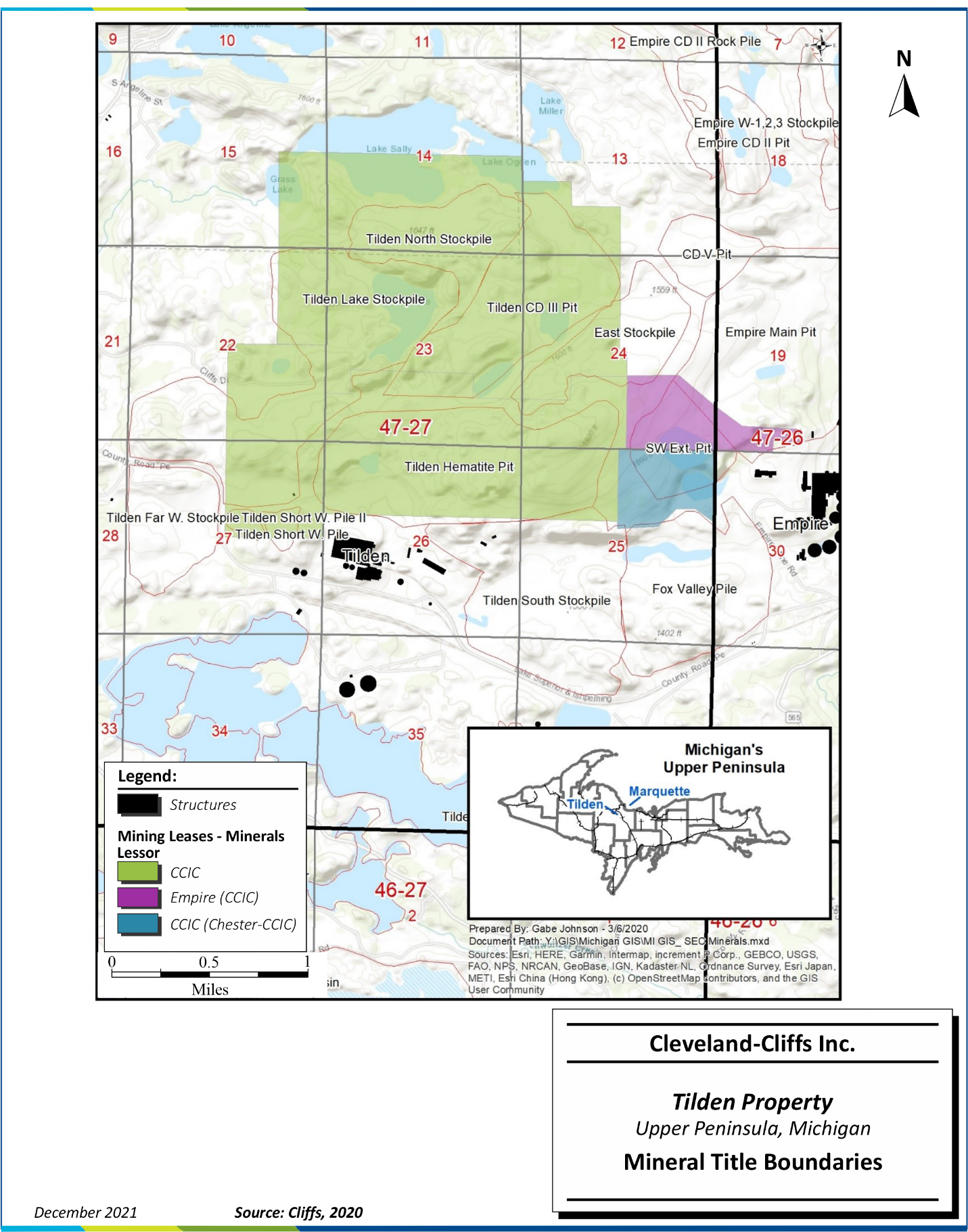

The Property consists of approximately 2,470 acres of mineral leases from three parties. Tilden leases approximately 2,210 acres directly from its affiliate, CCIC. Tilden subleases approximately 140 acres from Empire Iron Mining Partnership, another affiliate which leases the Property from CCIC. Tilden subleases the remaining, approximately 120 acres from CCIC, which leases the Property from the Chester Company (2/3 undivided interest) and CCIC (1/3 undivided interest), as illustrated in Figure 3-2. Mineral leases include surface mining rights. Land tenure is summarized in Table 3-1.

Both Tilden subleases expire in 2061; the CCIC lease is through the life of mine (LOM). In order to maintain the mineral leases until their expiration, Tilden L.C. must continue to make minimum prepaid royalty payments each quarter and pay property taxes. When mining occurs, a royalty is due per long ton of crude ore mined or long ton of pellets produced from the crude ore mined, and payable to the respective lessors quarterly. Royalty rates per long ton fluctuate based on industry and economic indexes. Minimum prepaid royalty payments may be credited against royalties due when mining occurs. Specific terms and provisions of the mineral leases are confidential.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 23

Figure 3-1: Location Map

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 24

Figure 3-2: Mineral Title Boundaries

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 25

Table 3-1: Land Tenure

Cleveland-Cliffs Inc. – Tilden Property

| | | | | |

| Lease Name | Expiration Date |

| Empire Mining Sublease | 6/1/2061 |

| CCIC Mining Sublease | 6/1/2061 |

| CCIC Supplemental Lease | 12/31/2070 |

3.2.2Surface Rights

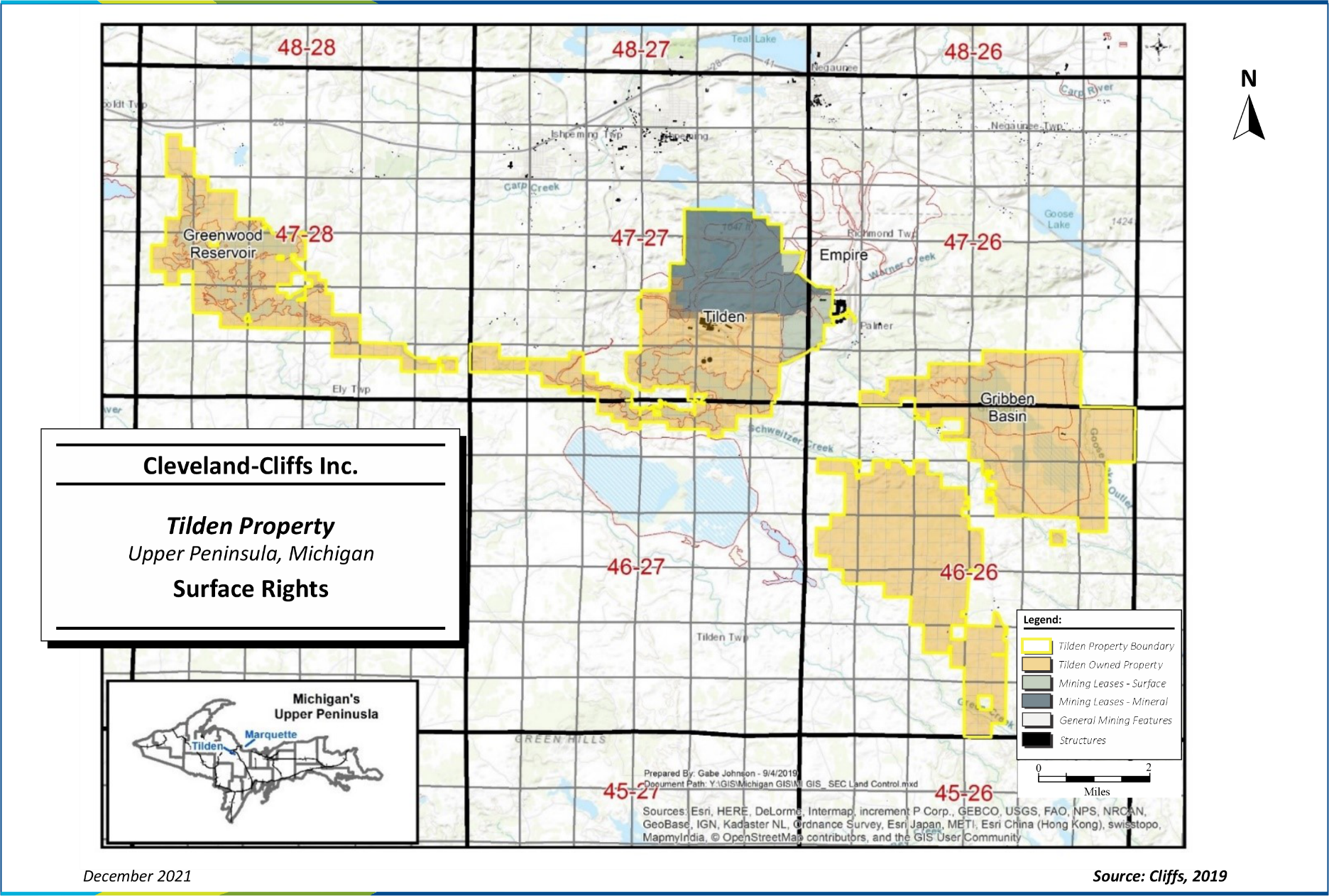

Surface rights consist of approximately 21,100 acres of owned property in and around the Mine, Plant, Greenwood Reservoir, and the Gribben Basin, as illustrated in Figure 3-3. To maintain ownership, property taxes must be paid to the local government units in Marquette County.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 26

Figure 3-3: Surface Rights

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 27

3.3Encumbrances

Tilden grants leases, licenses, and easements for various purposes including miscellaneous community land uses, utility infrastructure, and other third-party uses that encumber the Property but do not materially inhibit operations. Certain assets of Tilden L.C. serve as collateral as part of Cliffs’ asset-based lending (ABL) facility. Cliffs has outstanding standby letters of credit, which were issued to back certain obligations of Tilden L.C., including certain permits and tailings basin projects. Additionally, Tilden has and may continue to enter into lease agreements for necessary equipment used in the operations of the mine.

3.4Royalties

Reference section 3.2 for royalty information. No overriding royalty agreements are in place.

3.5Other Significant Factors and Risks

No additional significant factors or risks are known.

SLR is not aware of any environmental liabilities on the Property. Cleveland-Cliffs Inc. has all required permits to conduct the proposed work on the Property. SLR is not aware of any other significant factors and risks that may affect access, title, or the right or ability to perform the proposed work program on the Property.

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 28

4.0ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

4.1Accessibility

The Property is located close to the cities of Marquette, Negaunee, and Ishpeming, Michigan. The Mine can be accessed by the Tilden entrance gate near the community of National Mine, located two miles south of Ishpeming on County Road 476. Alternatively, the Property can be accessed from the east through the adjacent Empire Mine. The Empire entrance gate is located on M-35, nine miles south of US Highway 41 between Marquette and Negaunee. Sawyer International Airport, the closest public airport, is located 17 mi south of Marquette and serves the region with several flights daily to major hubs in Minneapolis, Chicago, and Detroit.

4.2Climate

Michigan’s Upper Peninsula has a humid continental climate, typified by large seasonal temperature differences. Summers are generally warm and humid; winters are cold and long. Precipitation in the area averages approximately 31 in. of rain and 102 in. of snow in the winter (Western Regional Climate Center, 2015). The average maximum and minimum temperatures are shown in Table 4-1, along with the average precipitation and snowfall. Snowfall in the region is greatly influenced by the “lake effect” due to proximity to the Great Lakes. Many towns in the Upper Peninsula have recorded annual snowfalls in excess of 350 in., and storms can quickly reach whiteout conditions and last for days (Albert, 1995).

The Property is a year-round operation and is not generally curtailed due to seasonal temperature changes or weather conditions.

Table 4-1: Ishpeming, MI Temperature and Precipitation

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Station 204127 | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | Annual |

Average Max. Temperature (oF) | 23.2 | 29.6 | 38.5 | 52.9 | 66.0 | 73.8 | 79.6 | 76.1 | 65.8 | 53.9 | 38.0 | 26.6 | 52.2 |

Average Min. Temperature (oF) | 5.2 | 10.5 | 17.7 | 29.2 | 40.0 | 48.0 | 54.4 | 52.8 | 44.8 | 35.3 | 23.2 | 11.4 | 31.1 |

| Average Total Precipitation (in.) | 1.5 | 1.3 | 2.0 | 2.7 | 2.7 | 3.0 | 3.4 | 3.5 | 3.7 | 3.7 | 2.3 | 1.9 | 31.4 |

| Average Total Snow Fall (in.) | 20.0 | 17.6 | 16.6 | 8.2 | 1.2 | 0.1 | 0.0 | 0.0 | 0.2 | 3.8 | 15.4 | 19.1 | 102.1 |

| Average Snow Depth (in.) | 15.0 | 21.0 | 16.0 | 3.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 2.0 | 8.0 | 5.0 |

4.3Local Resources

Local and State infrastructure includes hospitals, schools, airports, equipment suppliers, fuel suppliers, and communication systems. The Property is located approximately five miles south of the city of Ishpeming, Michigan, nine miles southwest of Negaunee, Michigan, and 20 mi west-southwest of

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 29

Marquette, Michigan. Medical facilities with trauma centers are located in the cities of Marquette and Green Bay. Table 4-2 is a list of the major population centers and the distance by road to the Property.

Table 4-2: Nearby Population Centers

Cleveland-Cliffs Inc. – Tilden Property

| | | | | | | | | | | |

| City/Town | Medical Center | Population 2010 Census | Mileage to Mine |

| Palmer, MI | n/a | 449 | 3.5 |

| Ishpeming, MI | ER | 6,470 | 5.0 |

| Negaunee, MI | n/a | 4,568 | 9.0 |

| Marquette, MI | Level II | 21,355 | 20.0 |

| Green Bay, WI | Level II and III | 104,057 | 167 |

Source: U.S. Census Bureau, Google Maps

The Tilden operation employs a total of 967 salaried and hourly employees, including Lake Superior & Ishpeming Railroad (LS&I) railroad staff, as of Q4 2021. The majority of the employees live within a 50 mi radius of the Property.

4.4Infrastructure

The Property is located in a historically important, iron-producing region in Northern Michigan. All infrastructure necessary to mine and process significant commercial quantities of iron ore exist at the current time. Infrastructure items include administration buildings and offices, maintenance shops, high-voltage electrical supplies, natural gas pipelines that connect into the North American distribution system, concentrator, pelletizing plant, water sources, paved roads and highways, railroads for transporting raw materials and final product, port facilities that connect into the Great Lakes, and towns where employees live. Additional details regarding Tilden infrastructure are provided in Section 15.0 of this TRS.

4.5Physiography

The Property is within the limits of a topographic region known as the Superior Uplands, a part of the Canadian Shield. This region is more rugged than the eastern portion of the Upper Peninsula, as it is dominated by Precambrian volcanic rocks and Archean basement rocks that were eroded down over many glaciation events. The Tilden Mine property features elevations ranging from approximately 1,300 fasl to 1,800 fasl. Topography is hilly and is dominated by glacially influenced landforms. Tilden is located in the Western Upper Peninsula Ecoregion (Section IX) and characterized by a landscape featuring moraines, drumlins, lake plains, outwash channels, outwash plains, and glacially eroded bedrock ridges (Albert, 1995).

Vegetation in the vicinity of Tilden is described as northern hardwood forest dominated by sugar maple, eastern hemlock, basswood, yellow birch, and sparse white pine. The Western Upper Peninsula Ecoregion also contains numerous bogs, tamarack-black spruce swamps, and hardwood-conifer swamps. The bogs and wetlands include elm, green and black ash, and red and sugar maple. Upland wetlands (remnants of glacial lakebeds) support ash, red maple, pin oak, and swamp white oak, whereas acidic,

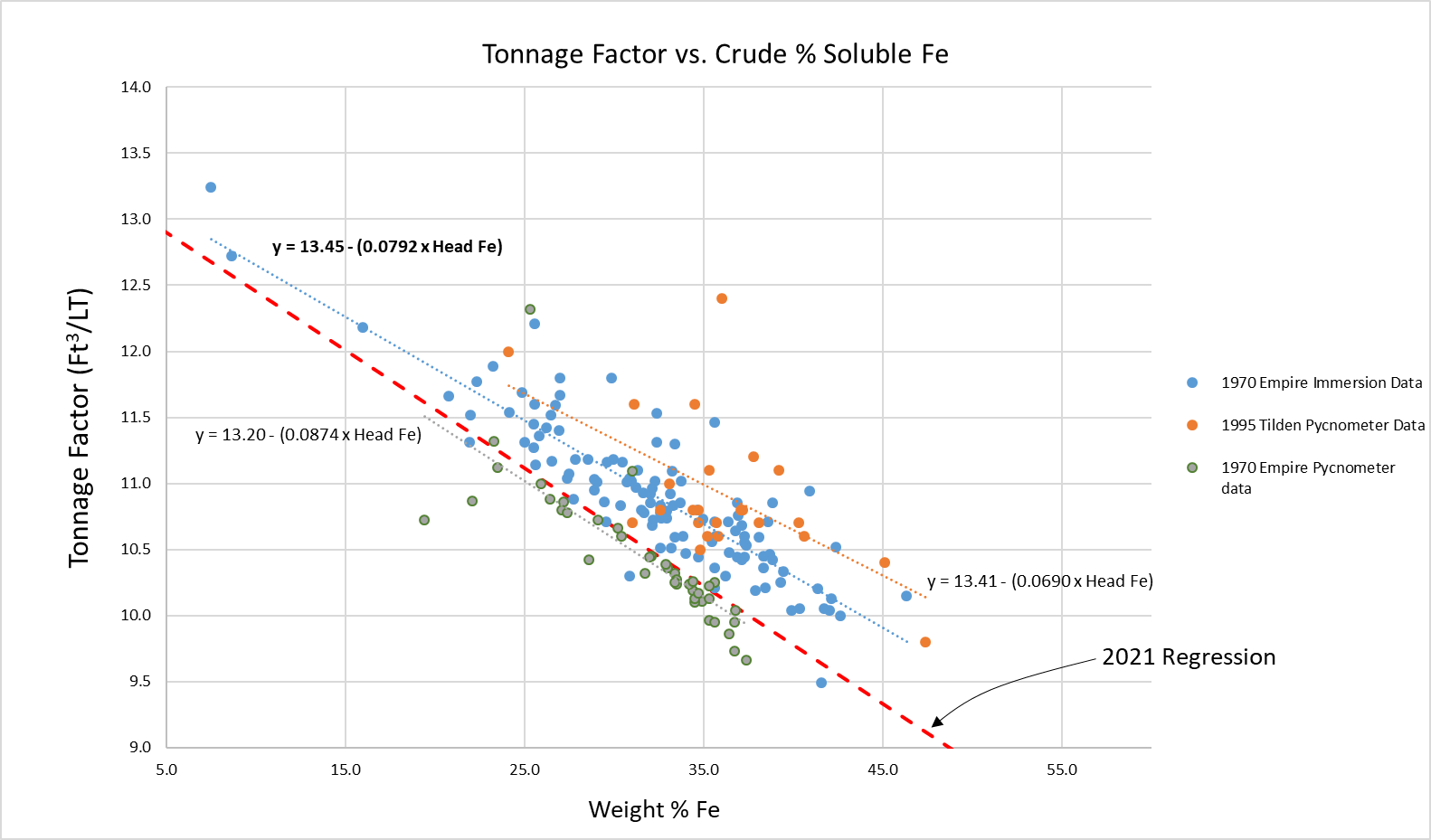

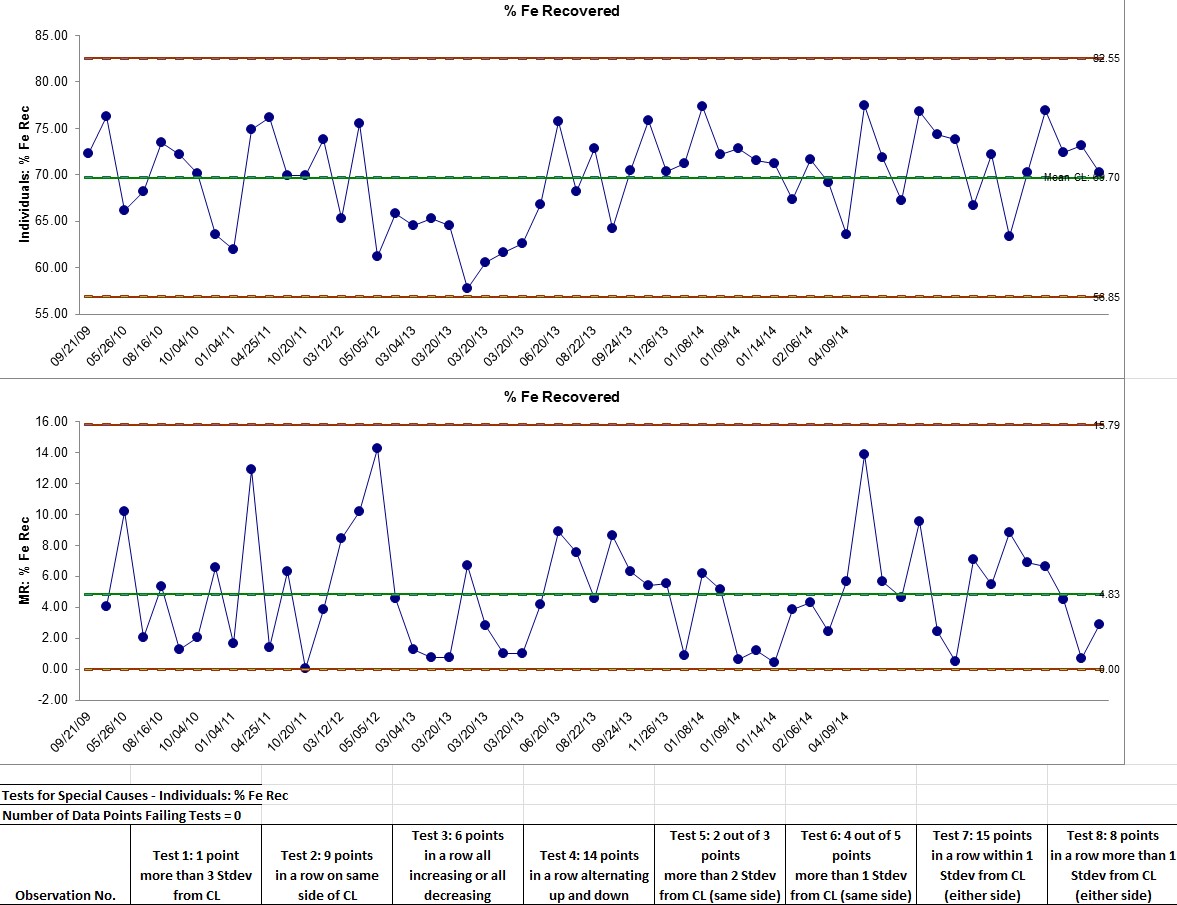

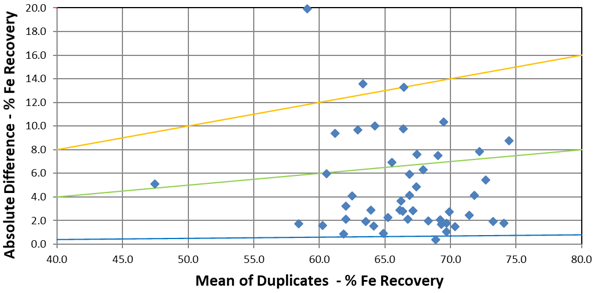

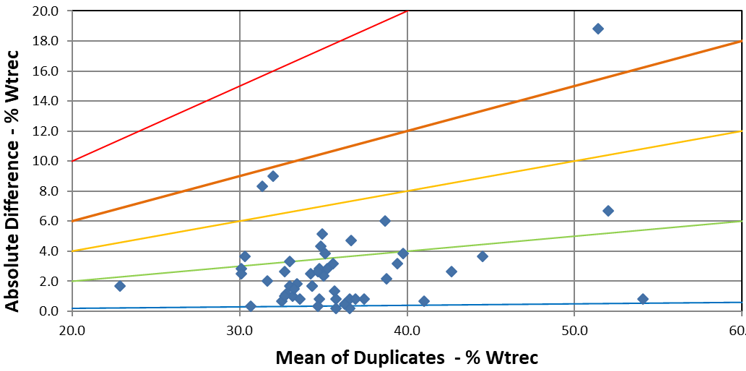

Cleveland-Cliffs Inc. | Tilden Property, SLR Project No: 138.02467.00001