00007640652022FYfalsehttp://fasb.org/us-gaap/2022#PropertyPlantAndEquipmentNethttp://fasb.org/us-gaap/2022#PropertyPlantAndEquipmentNetImplemented236648508516031295P1Yhttp://fasb.org/us-gaap/2022#OtherLiabilitieshttp://fasb.org/us-gaap/2022#OtherLiabilitieshttp://fasb.org/us-gaap/2022#OtherLiabilitiesCurrenthttp://fasb.org/us-gaap/2022#OtherLiabilitiesCurrenthttp://fasb.org/us-gaap/2022#OtherLiabilitiesNoncurrenthttp://fasb.org/us-gaap/2022#OtherLiabilitiesNoncurrent00007640652022-01-012022-12-3100007640652022-06-30iso4217:USD00007640652023-02-13xbrli:shares00007640652022-12-3100007640652021-12-31iso4217:USDxbrli:shares00007640652021-01-012021-12-3100007640652020-01-012020-12-310000764065clf:FerrousProcessingAndTradingMember2022-01-012022-12-310000764065clf:FerrousProcessingAndTradingMember2021-01-012021-12-310000764065clf:FerrousProcessingAndTradingMember2020-01-012020-12-310000764065clf:ArcelorMittalUSAMember2022-01-012022-12-310000764065clf:ArcelorMittalUSAMember2021-01-012021-12-310000764065clf:ArcelorMittalUSAMember2020-01-012020-12-310000764065clf:AKSteelMember2022-01-012022-12-310000764065clf:AKSteelMember2021-01-012021-12-310000764065clf:AKSteelMember2020-01-012020-12-3100007640652020-12-3100007640652019-12-310000764065us-gaap:CommonStockMember2019-12-310000764065us-gaap:AdditionalPaidInCapitalMember2019-12-310000764065us-gaap:RetainedEarningsMember2019-12-310000764065us-gaap:TreasuryStockMember2019-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2019-12-310000764065us-gaap:NoncontrollingInterestMember2019-12-310000764065us-gaap:RetainedEarningsMember2020-01-012020-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2020-01-012020-12-310000764065us-gaap:NoncontrollingInterestMember2020-01-012020-12-310000764065us-gaap:CommonStockMember2020-01-012020-12-310000764065us-gaap:AdditionalPaidInCapitalMember2020-01-012020-12-310000764065us-gaap:TreasuryStockMember2020-01-012020-12-310000764065us-gaap:CommonStockMemberclf:AKSteelMember2020-01-012020-12-310000764065us-gaap:AdditionalPaidInCapitalMemberclf:AKSteelMember2020-01-012020-12-310000764065us-gaap:NoncontrollingInterestMemberclf:AKSteelMember2020-01-012020-12-310000764065us-gaap:CommonStockMemberclf:ArcelorMittalUSAMember2020-01-012020-12-310000764065us-gaap:AdditionalPaidInCapitalMemberclf:ArcelorMittalUSAMember2020-01-012020-12-310000764065us-gaap:NoncontrollingInterestMemberclf:ArcelorMittalUSAMember2020-01-012020-12-310000764065us-gaap:CommonStockMember2020-12-310000764065us-gaap:AdditionalPaidInCapitalMember2020-12-310000764065us-gaap:RetainedEarningsMember2020-12-310000764065us-gaap:TreasuryStockMember2020-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2020-12-310000764065us-gaap:NoncontrollingInterestMember2020-12-310000764065us-gaap:RetainedEarningsMember2021-01-012021-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2021-01-012021-12-310000764065us-gaap:NoncontrollingInterestMember2021-01-012021-12-310000764065us-gaap:CommonStockMember2021-01-012021-12-310000764065us-gaap:AdditionalPaidInCapitalMember2021-01-012021-12-310000764065us-gaap:TreasuryStockMember2021-01-012021-12-310000764065us-gaap:NoncontrollingInterestMemberclf:ArcelorMittalUSAMember2021-01-012021-12-310000764065us-gaap:CommonStockMember2021-12-310000764065us-gaap:AdditionalPaidInCapitalMember2021-12-310000764065us-gaap:RetainedEarningsMember2021-12-310000764065us-gaap:TreasuryStockMember2021-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2021-12-310000764065us-gaap:NoncontrollingInterestMember2021-12-310000764065us-gaap:RetainedEarningsMember2022-01-012022-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2022-01-012022-12-310000764065us-gaap:NoncontrollingInterestMember2022-01-012022-12-310000764065us-gaap:CommonStockMember2022-01-012022-12-310000764065us-gaap:AdditionalPaidInCapitalMember2022-01-012022-12-310000764065us-gaap:TreasuryStockMember2022-01-012022-12-310000764065us-gaap:CommonStockMember2022-12-310000764065us-gaap:AdditionalPaidInCapitalMember2022-12-310000764065us-gaap:RetainedEarningsMember2022-12-310000764065us-gaap:TreasuryStockMember2022-12-310000764065us-gaap:AccumulatedOtherComprehensiveIncomeMember2022-12-310000764065us-gaap:NoncontrollingInterestMember2022-12-31clf:employee0000764065us-gaap:WorkforceSubjectToCollectiveBargainingArrangementsMember2022-12-31clf:segment0000764065us-gaap:OtherNoncurrentAssetsMember2022-12-310000764065us-gaap:OtherNoncurrentAssetsMember2021-12-310000764065srt:MinimumMemberus-gaap:LandImprovementsMember2022-01-012022-12-310000764065srt:MaximumMemberus-gaap:LandImprovementsMember2022-01-012022-12-310000764065srt:MinimumMemberus-gaap:BuildingMember2022-01-012022-12-310000764065srt:MaximumMemberus-gaap:BuildingMember2022-01-012022-12-310000764065srt:MinimumMemberus-gaap:EquipmentMember2022-01-012022-12-310000764065srt:MaximumMemberus-gaap:EquipmentMember2022-01-012022-12-310000764065us-gaap:CommonStockMemberclf:ArcelorMittalUSAMember2022-01-012022-12-310000764065us-gaap:CommonStockMemberclf:ArcelorMittalUSAMember2021-01-012021-12-310000764065us-gaap:CommonStockMemberclf:ArcelorMittalUSAMember2020-01-012020-12-310000764065us-gaap:SeriesBPreferredStockMemberclf:ArcelorMittalUSAMember2022-01-012022-12-310000764065us-gaap:SeriesBPreferredStockMemberclf:ArcelorMittalUSAMember2021-01-012021-12-310000764065us-gaap:SeriesBPreferredStockMemberclf:ArcelorMittalUSAMember2020-01-012020-12-310000764065us-gaap:CommonStockMemberclf:AKSteelMember2022-01-012022-12-310000764065us-gaap:CommonStockMemberclf:AKSteelMember2021-01-012021-12-310000764065us-gaap:CommonStockMemberclf:AKSteelMember2020-01-012020-12-310000764065us-gaap:StockCompensationPlanMemberclf:AKSteelMember2022-01-012022-12-310000764065us-gaap:StockCompensationPlanMemberclf:AKSteelMember2021-01-012021-12-310000764065us-gaap:StockCompensationPlanMemberclf:AKSteelMember2020-01-012020-12-310000764065clf:FerrousProcessingAndTradingMember2021-11-182021-12-310000764065clf:FerrousProcessingAndTradingMember2021-11-182021-11-180000764065clf:FerrousProcessingAndTradingMember2021-11-180000764065clf:FerrousProcessingAndTradingMember2021-11-192022-12-310000764065clf:FerrousProcessingAndTradingMember2022-12-310000764065us-gaap:CustomerRelationshipsMemberclf:FerrousProcessingAndTradingMember2021-11-182021-11-180000764065clf:SupplierRelationshipsMemberclf:FerrousProcessingAndTradingMember2021-11-182021-11-180000764065us-gaap:TrademarksAndTradeNamesMemberclf:FerrousProcessingAndTradingMember2021-11-182021-11-180000764065us-gaap:CommonStockMemberclf:ArcelorMittalUSAMember2020-12-092020-12-090000764065us-gaap:SeriesBPreferredStockMember2020-12-092020-12-090000764065clf:ArcelorMittalUSAMember2020-12-092020-12-0900007640652020-12-092020-12-090000764065us-gaap:CommonStockMemberclf:ArcelorMittalUSAMember2020-12-090000764065us-gaap:SeriesBPreferredStockMemberclf:ArcelorMittalUSAMember2020-12-092020-12-090000764065us-gaap:SeriesBPreferredStockMemberclf:ArcelorMittalUSAMember2020-12-090000764065clf:ArcelorMittalUSAMember2020-12-090000764065clf:ArcelorMittalUSAMember2020-12-092021-12-310000764065clf:ArcelorMittalUSAMember2021-12-310000764065clf:AKSteelMember2020-03-132020-03-13xbrli:pure0000764065us-gaap:CommonStockMemberclf:AKSteelMember2020-03-130000764065us-gaap:CommonStockMemberclf:AKSteelMember2020-03-132020-03-130000764065clf:AKSteelMember2020-03-130000764065us-gaap:RevolvingCreditFacilityMemberclf:AKSteelMember2020-03-132020-03-130000764065clf:A75002023AKSeniorNotesMemberclf:AKSteelMember2020-03-132020-03-130000764065clf:AKSteelMember2020-03-142021-03-310000764065clf:AKSteelMember2021-03-3100007640652020-03-142021-03-310000764065us-gaap:CustomerRelationshipsMemberclf:AKSteelMember2020-03-132020-03-130000764065us-gaap:TechnologyBasedIntangibleAssetsMemberclf:AKSteelMember2020-03-132020-03-130000764065us-gaap:TrademarksAndTradeNamesMemberclf:AKSteelMember2020-03-132020-03-130000764065clf:ArcelorMittalUSAAndAKSteelMember2020-01-012020-12-310000764065clf:ArcelorMittalUSAAndAKSteelMemberus-gaap:IntersegmentEliminationMember2020-01-012020-12-310000764065clf:ArcelorMittalUSAAndAKSteelMemberus-gaap:FairValueAdjustmentToInventoryMember2020-01-012020-12-310000764065clf:ArcelorMittalUSAAndAKSteelMemberus-gaap:AcquisitionRelatedCostsMember2020-01-012020-12-310000764065clf:RestructuringCostsMemberclf:ArcelorMittalUSAMember2020-01-012020-12-310000764065us-gaap:FranchiseMemberclf:ArcelorMittalUSAAndAKSteelMember2020-01-012020-12-310000764065clf:SteelmakingMemberclf:AutomotiveMember2022-01-012022-12-310000764065clf:SteelmakingMemberclf:AutomotiveMember2021-01-012021-12-310000764065clf:SteelmakingMemberclf:AutomotiveMember2020-01-012020-12-310000764065clf:SteelmakingMemberclf:InfrastructureAndManufacturingMember2022-01-012022-12-310000764065clf:SteelmakingMemberclf:InfrastructureAndManufacturingMember2021-01-012021-12-310000764065clf:SteelmakingMemberclf:InfrastructureAndManufacturingMember2020-01-012020-12-310000764065clf:DistributorsAndConvertersMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:DistributorsAndConvertersMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:DistributorsAndConvertersMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:SteelProducersMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:SteelProducersMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:SteelProducersMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:SteelmakingMember2022-01-012022-12-310000764065clf:SteelmakingMember2021-01-012021-12-310000764065clf:SteelmakingMember2020-01-012020-12-310000764065clf:OtherBusinessesMemberclf:AutomotiveMember2022-01-012022-12-310000764065clf:OtherBusinessesMemberclf:AutomotiveMember2021-01-012021-12-310000764065clf:OtherBusinessesMemberclf:AutomotiveMember2020-01-012020-12-310000764065clf:OtherBusinessesMemberclf:InfrastructureAndManufacturingMember2022-01-012022-12-310000764065clf:OtherBusinessesMemberclf:InfrastructureAndManufacturingMember2021-01-012021-12-310000764065clf:OtherBusinessesMemberclf:InfrastructureAndManufacturingMember2020-01-012020-12-310000764065clf:DistributorsAndConvertersMemberclf:OtherBusinessesMember2022-01-012022-12-310000764065clf:DistributorsAndConvertersMemberclf:OtherBusinessesMember2021-01-012021-12-310000764065clf:DistributorsAndConvertersMemberclf:OtherBusinessesMember2020-01-012020-12-310000764065clf:OtherBusinessesMember2022-01-012022-12-310000764065clf:OtherBusinessesMember2021-01-012021-12-310000764065clf:OtherBusinessesMember2020-01-012020-12-310000764065clf:HotRolledSteelMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:HotRolledSteelMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:HotRolledSteelMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:ColdRolledSteelMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:ColdRolledSteelMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:ColdRolledSteelMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:CoatedSteelMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:CoatedSteelMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:CoatedSteelMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:SteelmakingMemberclf:StainlessAndElectricalSteelMember2022-01-012022-12-310000764065clf:SteelmakingMemberclf:StainlessAndElectricalSteelMember2021-01-012021-12-310000764065clf:SteelmakingMemberclf:StainlessAndElectricalSteelMember2020-01-012020-12-310000764065clf:PlateMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:PlateMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:PlateMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:OtherSteelProductsMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:OtherSteelProductsMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:OtherSteelProductsMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:OtherMemberclf:SteelmakingMember2022-01-012022-12-310000764065clf:OtherMemberclf:SteelmakingMember2021-01-012021-12-310000764065clf:OtherMemberclf:SteelmakingMember2020-01-012020-12-310000764065clf:OtherBusinessesMemberclf:OtherMember2022-01-012022-12-310000764065clf:OtherBusinessesMemberclf:OtherMember2021-01-012021-12-310000764065clf:OtherBusinessesMemberclf:OtherMember2020-01-012020-12-310000764065clf:CorporateandOtherSegmentsMember2022-01-012022-12-310000764065clf:CorporateandOtherSegmentsMember2021-01-012021-12-310000764065clf:CorporateandOtherSegmentsMember2020-01-012020-12-310000764065clf:EBITDACalculationMember2022-01-012022-12-310000764065clf:EBITDACalculationMember2021-01-012021-12-310000764065clf:EBITDACalculationMember2020-01-012020-12-310000764065clf:AdjustedEBITDACalculationMember2022-01-012022-12-310000764065clf:AdjustedEBITDACalculationMember2021-01-012021-12-310000764065clf:AdjustedEBITDACalculationMember2020-01-012020-12-310000764065clf:SteelmakingMemberus-gaap:OperatingSegmentsMember2022-12-310000764065clf:SteelmakingMemberus-gaap:OperatingSegmentsMember2021-12-310000764065clf:OtherBusinessesMemberus-gaap:OperatingSegmentsMember2022-12-310000764065clf:OtherBusinessesMemberus-gaap:OperatingSegmentsMember2021-12-310000764065us-gaap:OperatingSegmentsMember2022-12-310000764065us-gaap:OperatingSegmentsMember2021-12-310000764065clf:CorporateandOtherSegmentsMember2022-12-310000764065clf:CorporateandOtherSegmentsMember2021-12-310000764065country:US2022-01-012022-12-310000764065country:US2021-01-012021-12-310000764065country:US2020-01-012020-12-310000764065country:CA2022-01-012022-12-310000764065country:CA2021-01-012021-12-310000764065country:CA2020-01-012020-12-310000764065clf:OtherCountriesMember2022-01-012022-12-310000764065clf:OtherCountriesMember2021-01-012021-12-310000764065clf:OtherCountriesMember2020-01-012020-12-310000764065country:US2022-12-310000764065country:US2021-12-310000764065country:US2020-12-310000764065country:CA2022-12-310000764065country:CA2021-12-310000764065country:CA2020-12-310000764065clf:OtherCountriesMember2022-12-310000764065clf:OtherCountriesMember2021-12-310000764065clf:OtherCountriesMember2020-12-310000764065clf:LandlandimprovementsandmineralrightsMember2022-12-310000764065clf:LandlandimprovementsandmineralrightsMember2021-12-310000764065us-gaap:BuildingMember2022-12-310000764065us-gaap:BuildingMember2021-12-310000764065us-gaap:MachineryAndEquipmentMember2022-12-310000764065us-gaap:MachineryAndEquipmentMember2021-12-310000764065us-gaap:OtherCapitalizedPropertyPlantAndEquipmentMember2022-12-310000764065us-gaap:OtherCapitalizedPropertyPlantAndEquipmentMember2021-12-310000764065us-gaap:ConstructionInProgressMember2022-12-310000764065us-gaap:ConstructionInProgressMember2021-12-310000764065clf:MiddletownMember2022-01-012022-12-310000764065clf:IndianaHarborMember2022-01-012022-12-310000764065clf:SteelmakingMember2022-12-310000764065clf:SteelmakingMember2021-12-310000764065clf:OtherBusinessesMember2022-12-310000764065clf:OtherBusinessesMember2021-12-310000764065us-gaap:CustomerRelationshipsMember2022-12-310000764065us-gaap:CustomerRelationshipsMember2021-12-310000764065us-gaap:TechnologyBasedIntangibleAssetsMember2022-12-310000764065us-gaap:TechnologyBasedIntangibleAssetsMember2021-12-310000764065us-gaap:TradeNamesMember2022-12-310000764065us-gaap:TradeNamesMember2021-12-310000764065clf:MiningPermitsMember2022-12-310000764065clf:MiningPermitsMember2021-12-310000764065clf:SupplierRelationshipsMember2022-12-310000764065clf:SupplierRelationshipsMember2021-12-310000764065clf:ClevelandCliffsInc.Memberclf:A98752025SeniorSecuredNotesMember2022-12-310000764065clf:ClevelandCliffsInc.Memberclf:A98752025SeniorSecuredNotesMember2021-12-310000764065clf:A67502026SeniorSecuredNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A67502026SeniorSecuredNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:A15002025ConvertibleSeniorNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A15002025ConvertibleSeniorNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:A70002027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A70002027SeniorNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:AKSteelMemberclf:A70002027AKSeniorNotesMember2022-12-310000764065clf:AKSteelMemberclf:A70002027AKSeniorNotesMember2021-12-310000764065clf:A5.8752027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A5.8752027SeniorNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:A46252029SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A46252029SeniorNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:A48752031SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A48752031SeniorNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:A62502040SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-12-310000764065clf:A62502040SeniorNotesMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:IndustrialRevenueBondsMemberclf:AKSteelMember2022-12-310000764065clf:IndustrialRevenueBondsMemberclf:AKSteelMember2021-12-310000764065us-gaap:RevolvingCreditFacilityMemberclf:ClevelandCliffsInc.Member2022-12-310000764065us-gaap:RevolvingCreditFacilityMemberclf:ClevelandCliffsInc.Member2021-12-310000764065clf:A67502026SeniorSecuredNotesMemberus-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodTwoMemberclf:A67502026SeniorSecuredNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065clf:A67502026SeniorSecuredNotesMemberus-gaap:DebtInstrumentRedemptionPeriodThreeMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065clf:A67502026SeniorSecuredNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:A70002027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodTwoMemberclf:A70002027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodThreeMemberclf:A70002027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:A5.8752027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodTwoMemberclf:A5.8752027SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065clf:A5.8752027SeniorNotesMemberus-gaap:DebtInstrumentRedemptionPeriodThreeMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065clf:DebtInstrumentRedemptionPeriodOneUponEquityIssuanceMemberclf:A46252029SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:A46252029SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodTwoMemberclf:A46252029SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065clf:DebtInstrumentRedemptionPeriodOneUponEquityIssuanceMemberclf:A48752031SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:A48752031SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodTwoMemberclf:A48752031SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodThreeMemberclf:A48752031SeniorNotesMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065clf:A62502040SeniorNotesMemberus-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:UnsecuredDebtMemberclf:ClevelandCliffsInc.Member2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodOneMemberclf:AKSteelMemberclf:A70002027AKSeniorNotesMember2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodTwoMemberclf:AKSteelMemberclf:A70002027AKSeniorNotesMember2022-01-012022-12-310000764065us-gaap:DebtInstrumentRedemptionPeriodThreeMemberclf:AKSteelMemberclf:A70002027AKSeniorNotesMember2022-01-012022-12-310000764065us-gaap:RevolvingCreditFacilityMember2022-12-310000764065us-gaap:LetterOfCreditMemberus-gaap:LineOfCreditMember2022-12-310000764065us-gaap:RevolvingCreditFacilityMemberus-gaap:LineOfCreditMember2022-12-310000764065us-gaap:LetterOfCreditMember2022-12-310000764065clf:A15002025ConvertibleSeniorNotesMember2022-01-012022-12-310000764065clf:A98752025SeniorSecuredNotesMember2022-01-012022-12-310000764065clf:IndustrialRevenueBondsMember2022-01-012022-12-310000764065clf:A67502026SeniorSecuredNotesMember2022-01-012022-12-310000764065clf:A46252029SeniorNotesMember2022-01-012022-12-310000764065clf:A48752024SeniorSecuredNotesMember2022-01-012022-12-310000764065clf:A62502040SeniorNotesMember2022-01-012022-12-3100007640652022-09-300000764065srt:ScenarioForecastMember2023-01-0100007640652022-10-12clf:location00007640652022-10-3100007640652022-11-010000764065us-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:PensionPlansDefinedBenefitMember2020-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2020-12-310000764065us-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065us-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:PensionPlansDefinedBenefitMember2020-01-012020-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2020-01-012020-12-310000764065clf:ChangeinAssumptionsforDefinedBenefitPlansDiscountRatesMemberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangeinAssumptionsforDefinedBenefitPlansDiscountRatesMemberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangeinAssumptionsforDefinedBenefitPlansDiscountRatesMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangeinAssumptionsforDefinedBenefitPlansDiscountRatesMember2021-01-012021-12-310000764065clf:ChangeinAssumptionsforDefinedBenefitPlansDemographicMemberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangeinAssumptionsforDefinedBenefitPlansDemographicMemberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangeinAssumptionsforDefinedBenefitPlansDemographicMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangeinAssumptionsforDefinedBenefitPlansDemographicMember2021-01-012021-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansMortalityMemberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansMortalityMemberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansMortalityMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansMortalityMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-01-012021-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansPerCapitaClaimsMemberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansPerCapitaClaimsMemberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangesinAssumptionsforDefinedBenefitPlansPerCapitaClaimsMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangesinAssumptionsforDefinedBenefitPlansPerCapitaClaimsMember2021-01-012021-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansOtherActuarialGainLossMemberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansOtherActuarialGainLossMemberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansOtherActuarialGainLossMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansOtherActuarialGainLossMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-01-012021-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansActuarialGainLossMemberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065clf:ChangesinAssumptionsforDefinedBenefitPlansActuarialGainLossMemberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangesinAssumptionsforDefinedBenefitPlansActuarialGainLossMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:ChangesinAssumptionsforDefinedBenefitPlansActuarialGainLossMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:VebaTrustMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:DirectPaymentsMember2021-01-012021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:VebaTrustMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:DirectPaymentsMember2022-01-012022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:VebaTrustMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberclf:DirectPaymentsMember2022-12-310000764065us-gaap:FixedIncomeInvestmentsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:ExternallyManagedAssetsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:EquitySecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:EquitySecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:EquitySecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:EquitySecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:FixedIncomeInvestmentsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FixedIncomeInvestmentsMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FixedIncomeInvestmentsMember2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:StructuredFinanceMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:StructuredFinanceMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:StructuredFinanceMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:StructuredFinanceMember2021-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMember2021-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:NonUSAndOtherBondsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:HedgeFundsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:HedgeFundsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PrivateEquityFundsMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PrivateEquityFundsMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:StructuredCreditMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065clf:StructuredCreditMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065clf:StructuredCreditMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:StructuredCreditMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberclf:StructuredCreditMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberclf:StructuredCreditMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:StructuredCreditMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:StructuredCreditMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065clf:StructuredCreditMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065clf:StructuredCreditMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:RealEstateMember2022-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:RealEstateMember2021-12-310000764065us-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:CashMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:CashMemberus-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:CashMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:PensionPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel2Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:PensionPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Memberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Memberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:DefinedBenefitPlanEquitySecuritiesUsMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:DefinedBenefitPlanEquitySecuritiesNonUsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:USGovernmentAgenciesDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:DomesticCorporateDebtSecuritiesMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065us-gaap:HedgeFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065us-gaap:PrivateEquityFundsMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:FairValueInputsLevel3Memberclf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberclf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065clf:StructuredCreditMemberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:RealEstateMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Memberus-gaap:RealEstateMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Memberus-gaap:RealEstateMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Memberus-gaap:RealEstateMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:RealEstateMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:RealEstateMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:CashMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:CashMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMemberus-gaap:CashMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMember2021-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2022-12-310000764065us-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:FairValueMeasuredAtNetAssetValuePerShareMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2020-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:TrustForBenefitOfEmployeesMember2021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:TrustForBenefitOfEmployeesMember2020-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2022-01-012022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:PensionPlansDefinedBenefitMember2021-01-012021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:TrustForBenefitOfEmployeesMember2022-01-012022-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:TrustForBenefitOfEmployeesMember2021-01-012021-12-310000764065us-gaap:FairValueInputsLevel3Memberus-gaap:OtherPostretirementBenefitPlansDefinedBenefitMemberus-gaap:TrustForBenefitOfEmployeesMember2022-12-310000764065clf:SteelworkersPensionTrustMember2022-01-012022-12-310000764065clf:SteelworkersPensionTrustMember2021-01-012021-12-310000764065clf:SteelworkersPensionTrustMember2020-01-012020-12-310000764065clf:IAMNationalPensionFundsNationalPensionPlanMember2022-01-012022-12-310000764065clf:IAMNationalPensionFundsNationalPensionPlanMember2021-01-012021-12-310000764065clf:IAMNationalPensionFundsNationalPensionPlanMember2020-01-012020-12-310000764065clf:AmericanMaritimeOfficersPlanMember2022-01-012022-12-310000764065clf:AmericanMaritimeOfficersPlanMember2021-01-012021-12-310000764065clf:AmericanMaritimeOfficersPlanMember2020-01-012020-12-310000764065clf:SteelworkersPensionTrustMember2021-12-310000764065clf:A2021EquityPlanMember2022-01-012022-12-310000764065clf:AR2015EquityPlanMember2022-12-310000764065clf:A2021EquityPlanMember2022-12-310000764065us-gaap:CostOfSalesMember2022-01-012022-12-310000764065us-gaap:CostOfSalesMember2021-01-012021-12-310000764065us-gaap:CostOfSalesMember2020-01-012020-12-310000764065us-gaap:SellingGeneralAndAdministrativeExpensesMember2022-01-012022-12-310000764065us-gaap:SellingGeneralAndAdministrativeExpensesMember2021-01-012021-12-310000764065us-gaap:SellingGeneralAndAdministrativeExpensesMember2020-01-012020-12-310000764065us-gaap:AcquisitionRelatedCostsMember2022-01-012022-12-310000764065us-gaap:AcquisitionRelatedCostsMember2021-01-012021-12-310000764065us-gaap:AcquisitionRelatedCostsMember2020-01-012020-12-310000764065us-gaap:StockCompensationPlanMember2022-01-012022-12-310000764065us-gaap:StockCompensationPlanMember2021-01-012021-12-310000764065us-gaap:StockCompensationPlanMember2020-01-012020-12-310000764065us-gaap:PerformanceSharesMember2021-12-310000764065us-gaap:PerformanceSharesMember2020-12-310000764065us-gaap:PerformanceSharesMember2019-12-310000764065us-gaap:PerformanceSharesMember2022-01-012022-12-310000764065us-gaap:PerformanceSharesMember2021-01-012021-12-310000764065us-gaap:PerformanceSharesMember2020-01-012020-12-310000764065clf:AKSteelMemberus-gaap:PerformanceSharesMember2022-01-012022-12-310000764065clf:AKSteelMemberus-gaap:PerformanceSharesMember2021-01-012021-12-310000764065clf:AKSteelMemberus-gaap:PerformanceSharesMember2020-01-012020-12-310000764065us-gaap:PerformanceSharesMember2022-12-310000764065clf:AKSteelMemberclf:LongTermPerformancePlanMember2020-03-132020-03-130000764065clf:AKSteelMemberus-gaap:PerformanceSharesMember2020-03-132020-03-130000764065srt:MinimumMemberus-gaap:PerformanceSharesMember2022-01-012022-12-310000764065srt:MaximumMemberus-gaap:PerformanceSharesMember2022-01-012022-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2021-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2020-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2019-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2022-01-012022-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2021-01-012021-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2020-01-012020-12-310000764065us-gaap:RestrictedStockUnitsRSUMemberclf:AKSteelMember2022-01-012022-12-310000764065us-gaap:RestrictedStockUnitsRSUMemberclf:AKSteelMember2021-01-012021-12-310000764065us-gaap:RestrictedStockUnitsRSUMemberclf:AKSteelMember2020-01-012020-12-310000764065us-gaap:RestrictedStockUnitsRSUMember2022-12-310000764065us-gaap:EmployeeStockOptionMembersrt:MinimumMember2022-01-012022-12-310000764065us-gaap:EmployeeStockOptionMembersrt:MaximumMember2022-01-012022-12-310000764065srt:DirectorMemberus-gaap:ShareBasedPaymentArrangementNonemployeeMemberus-gaap:RestrictedStockUnitsRSUMemberclf:DirectorsPlanMember2022-12-310000764065srt:DirectorMemberus-gaap:ShareBasedPaymentArrangementNonemployeeMemberus-gaap:RestrictedStockUnitsRSUMemberclf:DirectorsPlanMember2021-12-310000764065srt:DirectorMemberus-gaap:ShareBasedPaymentArrangementNonemployeeMemberus-gaap:RestrictedStockUnitsRSUMemberclf:DirectorsPlanMember2020-12-310000764065clf:IncludedinincometaxexpensebenefitMember2022-01-012022-12-310000764065clf:IncludedinincometaxexpensebenefitMember2021-01-012021-12-310000764065clf:IncludedinincometaxexpensebenefitMember2020-01-012020-12-310000764065clf:IncreaseDecreaseFromAcquisitionsMember2022-01-012022-12-310000764065clf:IncreaseDecreaseFromAcquisitionsMember2021-01-012021-12-310000764065clf:IncreaseDecreaseFromAcquisitionsMember2020-01-012020-12-310000764065us-gaap:ForeignCountryMember2022-12-310000764065us-gaap:ForeignCountryMember2021-12-310000764065us-gaap:StateAndLocalJurisdictionMember2022-12-310000764065us-gaap:StateAndLocalJurisdictionMember2021-12-310000764065us-gaap:OtherCurrentLiabilitiesMember2022-12-310000764065us-gaap:OtherCurrentLiabilitiesMember2021-12-310000764065us-gaap:OtherNoncurrentLiabilitiesMember2022-12-310000764065us-gaap:OtherNoncurrentLiabilitiesMember2021-12-310000764065us-gaap:OtherLiabilitiesMember2022-12-310000764065us-gaap:SeniorNotesMemberus-gaap:CarryingReportedAmountFairValueDisclosureMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:SeniorNotesMemberus-gaap:EstimateOfFairValueFairValueDisclosureMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:SeniorNotesMemberus-gaap:CarryingReportedAmountFairValueDisclosureMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:SeniorNotesMemberus-gaap:EstimateOfFairValueFairValueDisclosureMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065clf:IndustrialRevenueBondsMemberus-gaap:CarryingReportedAmountFairValueDisclosureMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065us-gaap:EstimateOfFairValueFairValueDisclosureMemberclf:IndustrialRevenueBondsMemberus-gaap:FairValueInputsLevel1Member2022-12-310000764065clf:IndustrialRevenueBondsMemberus-gaap:CarryingReportedAmountFairValueDisclosureMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:EstimateOfFairValueFairValueDisclosureMemberclf:IndustrialRevenueBondsMemberus-gaap:FairValueInputsLevel1Member2021-12-310000764065us-gaap:RevolvingCreditFacilityMemberus-gaap:LineOfCreditMemberus-gaap:FairValueInputsLevel2Memberus-gaap:CarryingReportedAmountFairValueDisclosureMember2022-12-310000764065us-gaap:EstimateOfFairValueFairValueDisclosureMemberus-gaap:RevolvingCreditFacilityMemberus-gaap:LineOfCreditMemberus-gaap:FairValueInputsLevel2Member2022-12-310000764065us-gaap:RevolvingCreditFacilityMemberus-gaap:LineOfCreditMemberus-gaap:FairValueInputsLevel2Memberus-gaap:CarryingReportedAmountFairValueDisclosureMember2021-12-310000764065us-gaap:EstimateOfFairValueFairValueDisclosureMemberus-gaap:RevolvingCreditFacilityMemberus-gaap:LineOfCreditMemberus-gaap:FairValueInputsLevel2Member2021-12-310000764065us-gaap:CarryingReportedAmountFairValueDisclosureMember2022-12-310000764065us-gaap:EstimateOfFairValueFairValueDisclosureMember2022-12-310000764065us-gaap:CarryingReportedAmountFairValueDisclosureMember2021-12-310000764065us-gaap:EstimateOfFairValueFairValueDisclosureMember2021-12-310000764065srt:NaturalGasPerThousandCubicFeetMemberus-gaap:CommodityContractMember2022-12-31clf:MMBtu0000764065srt:NaturalGasPerThousandCubicFeetMemberus-gaap:CommodityContractMember2021-12-310000764065us-gaap:CommodityContractMemberclf:ZincMember2022-12-31clf:metricTons0000764065us-gaap:CommodityContractMemberclf:ZincMember2021-12-310000764065us-gaap:CommodityContractMemberus-gaap:ElectricityMember2022-12-31utr:MWh0000764065us-gaap:CommodityContractMemberus-gaap:ElectricityMember2021-12-310000764065us-gaap:CommodityContractMemberclf:TinMember2022-12-310000764065us-gaap:CommodityContractMemberclf:TinMember2021-12-310000764065us-gaap:OtherCurrentAssetsMember2022-12-310000764065us-gaap:OtherCurrentAssetsMember2021-12-3100007640652022-02-100000764065clf:A15002025ConvertibleSeniorNotesMember2021-12-012021-12-010000764065us-gaap:CommonStockMember2021-12-012021-12-0100007640652021-02-110000764065clf:ArcelorMittalMember2021-02-110000764065clf:A98752025SeniorSecuredNotesMember2021-03-112021-03-110000764065us-gaap:SeriesBPreferredStockMember2021-07-012021-09-3000007640652021-03-3100007640652021-04-290000764065us-gaap:SeriesAPreferredStockMember2022-12-310000764065us-gaap:SeriesBPreferredStockMember2022-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2021-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2020-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2019-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2022-01-012022-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2021-01-012021-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2020-01-012020-12-310000764065us-gaap:AccumulatedForeignCurrencyAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2022-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2021-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2020-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2019-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2022-01-012022-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2021-01-012021-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2020-01-012020-12-310000764065us-gaap:AccumulatedGainLossCashFlowHedgeIncludingNoncontrollingInterestMember2022-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2021-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2020-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2019-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2022-01-012022-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2021-01-012021-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2020-01-012020-12-310000764065us-gaap:AccumulatedDefinedBenefitPlansAdjustmentIncludingPortionAttributableToNoncontrollingInterestMember2022-12-310000764065clf:SunCokeMiddletownMemberus-gaap:VariableInterestEntityPrimaryBeneficiaryMember2022-01-012022-12-310000764065clf:SunCokeMiddletownMemberus-gaap:VariableInterestEntityPrimaryBeneficiaryMember2021-01-012021-12-310000764065clf:SunCokeMiddletownMemberus-gaap:VariableInterestEntityPrimaryBeneficiaryMember2022-12-310000764065clf:SunCokeMiddletownMemberus-gaap:VariableInterestEntityPrimaryBeneficiaryMember2021-12-31

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| | | | | | | | | | | |

| ☒ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 | |

For the fiscal year ended December 31, 2022

OR

| | | | | | | | | | | |

| ☐ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 | |

For the transition period from to

Commission File Number: 1-8944

CLEVELAND-CLIFFS INC.

(Exact name of registrant as specified in its charter)

| | | | | | | | | | | | | | | | | | | | |

| Ohio | | 34-1464672 | |

| (State or Other Jurisdiction of

Incorporation or Organization) | | (I.R.S. Employer

Identification No.) | |

| | | | | | |

| 200 Public Square, | Cleveland, | Ohio | | 44114-2315 | |

| (Address of Principal Executive Offices) | | (Zip Code) | |

Registrant’s telephone number, including area code: (216) 694-5700

Securities registered pursuant to Section 12(b) of the Act:

| | | | | | | | | | | | | | |

| Title of each class | | Trading Symbol(s) | | Name of each exchange on which registered |

| Common Shares, par value $0.125 per share | | CLF | | New York Stock Exchange |

Securities registered pursuant to section 12(g) of the Act: NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☒ NO ☐

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit such files). Yes ☒ No ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company, or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company,” and "emerging growth company" in Rule 12b-2 of the Exchange Act.

| | | | | | | | | | | |

| Large accelerated filer | ☒ | Accelerated filer | ☐ |

| Non-accelerated filer | ☐ | Smaller reporting company | ☐ |

| | Emerging growth company | ☐ |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

Indicate by check mark whether the registrant has filed a report on and attestation to its management’s assessment of the effectiveness of its internal control over financial reporting under Section 404(b) of the Sarbanes-Oxley Act (15 U.S.C. 7262(b)) by the registered public accounting firm that prepared or issued its audit report. ☒

If securities are registered pursuant to Section 12(b) of the Act, indicate by check mark whether the financial statements of the registrant included in the filing reflect the correction of an error to previously issued financial statements. ☐

Indicate by check mark whether any of those error corrections are restatements that required a recovery analysis of incentive-based compensation received by any of the registrant's executive officers during the relevant recovery period pursuant to §240.10D-1(b). ☐

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ☐ No ☒

As of June 30, 2022, the aggregate market value of the voting and non-voting common shares held by non-affiliates of the registrant, based on the closing price of $15.37 per share as reported on the New York Stock Exchange — Composite Index, was $7,844,058,129 (excluded from this figure are the voting shares beneficially owned by the registrant’s officers and directors).

The number of shares outstanding of the registrant’s common shares, par value $0.125 per share, was 514,787,304 as of February 13, 2023.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s proxy statement for its 2023 annual meeting of shareholders are incorporated by reference into Part III.

TABLE OF CONTENTS

| | | | | | | | | | | | | | | | | |

| | | | | |

| | | Page Number |

| | | | | |

| DEFINITIONS | | | |

| | | |

| PART I | | | |

| ITEM 1. | BUSINESS | | | |

| | Information About Our Executive Officers | | | |

| ITEM 1A. | RISK FACTORS | | | |

| ITEM 1B. | UNRESOLVED STAFF COMMENTS | | | |

| ITEM 2. | PROPERTIES | | | |

| ITEM 3. | LEGAL PROCEEDINGS | | | |

| ITEM 4. | MINE SAFETY DISCLOSURES | | | |

| | | | | |

| PART II | | | |

| ITEM 5. | MARKET FOR REGISTRANT'S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES OF EQUITY SECURITIES | | | |

| ITEM 6. | [Reserved] | | | |

| ITEM 7. | MANAGEMENT'S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS | | | |

| ITEM 7A. | QUANTITATIVE AND QUALITATIVE DISCLOSURES ABOUT MARKET RISK | | | |

| ITEM 8. | FINANCIAL STATEMENTS AND SUPPLEMENTARY DATA | | | |

| ITEM 9. | CHANGES IN AND DISAGREEMENTS WITH ACCOUNTANTS ON ACCOUNTING AND FINANCIAL DISCLOSURE | | | |

| ITEM 9A. | CONTROLS AND PROCEDURES | | | |

| ITEM 9B. | OTHER INFORMATION | | | |

| ITEM 9C. | DISCLOSURE REGARDING FOREIGN JURISDICTIONS THAT PREVENT INSPECTIONS | | | |

| | | |

PART III | | | |

| ITEM 10. | DIRECTORS, EXECUTIVE OFFICERS AND CORPORATE GOVERNANCE | | | |

| ITEM 11. | EXECUTIVE COMPENSATION | | | |

| ITEM 12. | SECURITY OWNERSHIP OF CERTAIN BENEFICIAL OWNERS AND MANAGEMENT AND RELATED STOCKHOLDER MATTERS | | | |

| ITEM 13. | CERTAIN RELATIONSHIPS AND RELATED TRANSACTIONS, AND DIRECTOR INDEPENDENCE | | | |

| ITEM 14. | PRINCIPAL ACCOUNTANT FEES AND SERVICES | | | |

| | | | | |

| PART IV | | | |

| ITEM 15. | EXHIBITS AND FINANCIAL STATEMENT SCHEDULES | | | |

| ITEM 16. | FORM 10-K SUMMARY | | | |

| | | |

| SIGNATURES | | | |

DEFINITIONS

The following abbreviations or acronyms are used in the text. References in this report to the “Company,” “we,” “us,” “our,” "Cleveland-Cliffs" and “Cliffs” are to Cleveland-Cliffs Inc. and subsidiaries, collectively. References to “$” is to United States currency.

| | | | | | | | |

| Abbreviation or acronym | | Term |

| 4.625% 2029 Senior Notes | | 4.625% Senior Guaranteed Notes due 2029 issued by Cleveland-Cliffs Inc. on February 17, 2021 in an aggregate principal amount of $500 million |

| 4.875% 2031 Senior Notes | | 4.875% Senior Guaranteed Notes due 2031 issued by Cleveland-Cliffs Inc. on February 17, 2021 in an aggregate principal amount of $500 million |

| 2012 Amended Equity Plan | | Cliffs Natural Resources Inc. 2012 Incentive Equity Plan, as amended or amended and restated from time to time |

| 2020 Acquisitions | | The AK Steel Merger and AM USA Transaction, collectively |

| 2021 Equity Plan | | Cleveland-Cliffs Inc. 2021 Equity and Incentive Compensation Plan |

| A&R 2015 Equity Plan | | Cliffs Natural Resources Inc. Amended and Restated 2015 Equity and Incentive Compensation Plan |

| ABL Facility | | Asset-Based Revolving Credit Agreement, dated as of March 13, 2020, among Cleveland-Cliffs Inc., the lenders party thereto from time to time and Bank of America, N.A., as administrative agent, as amended as of March 27, 2020, December 9, 2020 and December 17, 2021, and as may be further amended from time to time |

| Adjusted EBITDA | | EBITDA, excluding certain items such as EBITDA of noncontrolling interests, extinguishment of debt, acquisition-related expenses and adjustments, asset impairment and other, net |

| AG | | Autogenous grinding |

| AHSS | | Advanced high-strength steel |

| AK Steel | | AK Steel Holding Corporation (n/k/a Cleveland-Cliffs Steel Holding Corporation) and its consolidated subsidiaries, including AK Steel Corporation (n/k/a Cleveland-Cliffs Steel Corporation), its direct, wholly owned subsidiary, collectively, unless stated otherwise or the context indicates otherwise |

| AK Steel Merger | | The merger of Merger Sub with and into AK Steel, with AK Steel surviving the merger as a wholly owned subsidiary of Cleveland-Cliffs Inc., subject to the terms and conditions set forth in the Merger Agreement, consummated on March 13, 2020 |

| AM USA Transaction | | The acquisition of ArcelorMittal USA, consummated on December 9, 2020 |

| AM USA Transaction Agreement | | Transaction Agreement, dated as of September 28, 2020, by and between Cleveland-Cliffs Inc. and ArcelorMittal |

| AOCI | | Accumulated other comprehensive income (loss) |

| ArcelorMittal | | ArcelorMittal S.A., a company organized under the laws of Luxembourg and the former ultimate parent company of ArcelorMittal USA |

| ArcelorMittal USA | | Substantially all of the operations of the former ArcelorMittal USA LLC, its subsidiaries and certain affiliates, and Kote and Tek, collectively |

| ASC | | Accounting Standards Codification |

| ASU | | Accounting Standards Update |

| Board | | The Board of Directors of Cleveland-Cliffs Inc. |

| BOF | | Basic oxygen furnace |

| CAFE | | Corporate Average Fuel Economy |

| CARES Act | | Coronavirus Aid, Relief, and Economic Security Act |

| CERCLA | | Comprehensive Environmental Response, Compensation and Liability Act of 1980 |

| CHIPS Act | | Creating Helpful Incentives to Produce Semiconductors and Science Act of 2022 |

| Clean Water Act | | Federal Water Pollution Control Act |

| CN | | Canadian National Railway Company |

| Compensation Committee | | Compensation and Organization Committee of the Board |

| COVID-19 | | A novel strain of coronavirus that the World Health Organization declared a global pandemic in March 2020 |

| Directors’ Plan | | Cleveland-Cliffs Inc. 2021 Nonemployee Directors’ Compensation Plan |

| Dodd-Frank Act | | Dodd-Frank Wall Street Reform and Consumer Protection Act |

| DOE | | U.S. Department of Energy |

| DR-grade | | Direct reduction-grade |

| EAF | | Electric arc furnace |

| EBITDA | | Earnings before interest, taxes, depreciation and amortization |

| EDC | | Export Development Canada |

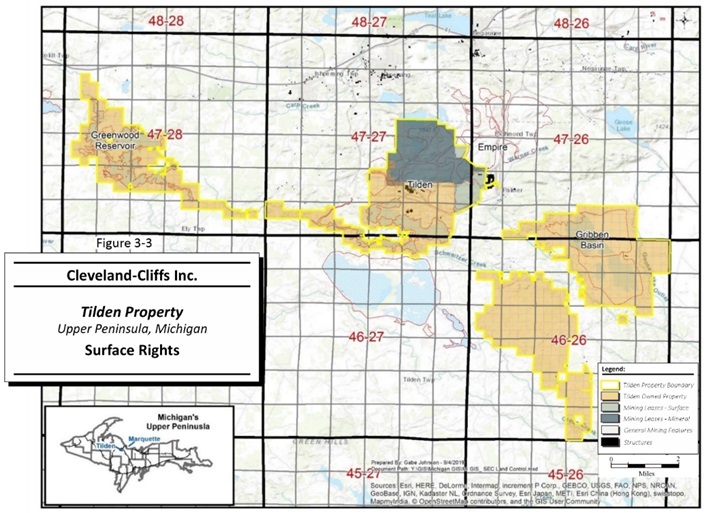

| Empire | | Iron ore mining property owned by Empire Iron Mining Partnership, an indirect, wholly owned subsidiary of Cliffs |

| | | | | | | | |

| Abbreviation or acronym | | Term |

| EPA | | U.S. Environmental Protection Agency |

| EPS | | Earnings per share |

| ERISA | | Employee Retirement Income Security Act of 1974, as amended |

| EV | | Electric vehicle |

| Exchange Act | | Securities Exchange Act of 1934, as amended |

| FASB | | Financial Accounting Standards Board |

| Fe | | Iron |

| FeT | | Total iron |

| FIP | | Federal implementation plan |

| FPT | | Ferrous Processing and Trading Company, including certain related entities |

| FPT Acquisition | | The purchase of FPT, subject to the terms and conditions set forth in the FPT Acquisition Agreement |

| FPT Acquisition Agreement | | Securities Purchase Agreement, dated as of October 8, 2021, by and between Cleveland-Cliffs Inc. and Anthony Soave Revocable Trust u/a/d January 14, 1987, as amended and restated |

| GAAP | | Accounting principles generally accepted in the United States |

| GHG | | Greenhouse gas |

| GOES | | Grain oriented electrical steel |

| HAP | | Hazardous air pollutant |

| HBI | | Hot briquetted iron |

| Hibbing | | Iron ore mining property owned by Hibbing Taconite Company, an unincorporated joint venture between subsidiaries of Cliffs and U.S. Steel |

| HRC | | Hot-rolled coil steel |

| HVAC | | Heating, ventilation and air conditioning equipment |

| IAM | | International Association of Machinists and Aerospace Workers |

| Inflation Reduction Act | | Inflation Reduction Act of 2022 |

| Infrastructure and Jobs Act | | Infrastructure Investment and Jobs Act of 2021 |