UNITED STATES SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2007

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number: 1-8944

Cleveland-Cliffs Inc

(Exact name of registrant as specified in its charter)

| Ohio | 34-1464672 | |

| (State or other jurisdiction of incorporation) |

(I.R.S. Employer Identification No.) | |

| 1100 Superior Avenue, Cleveland, Ohio |

44114-2544 | |

| (Address of principal executive offices) | (Zip Code) | |

Registrant’s telephone number, including area code: (216) 694-5700

Securities Registered Pursuant to Section 12(b) of the Act:

| Title of Each Class |

Name of Each Exchange on Which Registered | |

| Common Shares, par value $0.25 per share |

New York Stock Exchange and Chicago Stock Exchange | |

Securities Registered Pursuant to Section 12(g) of the Act:

NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes x No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of the Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer.

| Large accelerated filer x | Accelerated filer ¨ | Non-accelerated filer ¨ | Smaller reporting company ¨. |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12 b-2 of the Exchange Act). Yes ¨ No x

As of June 30, 2007, the aggregate market value of the voting and non-voting stock held by non-affiliates of the registrant, based on the closing price of $77.67 per share as reported on the New York Stock Exchange —Composite Index was $3,168,982,680 (excluded from this figure is the voting stock beneficially owned by the registrant’s officers and directors).

The number of shares outstanding of the registrant’s Common Shares, par value $0.25 per share, was 45,167,824 as of February 25, 2008.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s proxy statement for its annual meeting of shareholders scheduled to be held on May 13, 2008 are incorporated by reference into Part III.

| Page No. | ||||

| 2 | ||||

| Part I |

||||

| Item 1. |

4 | |||

| Item 1A. |

17 | |||

| Item 1B. |

24 | |||

| Item 2. |

24 | |||

| Item 3. |

32 | |||

| Item 4. |

34 | |||

| Part II |

||||

| Item 5. |

36 | |||

| Item 6. |

38 | |||

| Item 7. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

40 | ||

| Item 7A. |

62 | |||

| Item 8. |

63 | |||

| Item 9. |

Changes in and Disagreements With Accountants on Accounting and Financial Disclosure |

120 | ||

| Item 9A. |

120 | |||

| Part III |

||||

| Item 10. |

123 | |||

| Item 11. |

123 | |||

| Item 12. |

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

123 | ||

| Item 13. |

Certain Relationships and Related Transactions, and Director Independence |

124 | ||

| Item 14. |

124 | |||

| Part IV |

||||

| Item 15. |

125 | |||

| 126 | ||||

The following abbreviations or acronyms are used in the text. References in this report to the “Company”, “we”, “us”, “our” and “Cliffs” are to Cleveland-Cliffs Inc and subsidiaries, collectively. References to “A$” refer to Australian currency, “C$” to Canadian currency and “$” to United States currency.

| Abbreviation or acronym |

Term | |

| AEPA |

Australian Environmental Protection Authority | |

| Algoma |

Algoma Steel Inc. | |

| Amapa Project |

MMX Amapá Mineração Limitada | |

| ASC |

American Steamship Company | |

| AOC |

Administrative Order by Consent | |

| APBO |

Accumulated other postretirement benefit obligation | |

| ARB |

Accounting Research Bulletin | |

| ARS |

Auction rate securities | |

| BHP |

BHP Billiton | |

| CAC |

Cliffs Australia Coal Pty Ltd. | |

| CAL |

Cliffs and Associates Limited | |

| CAWO |

Cliffs Australian Washplant Operations Pty Ltd | |

| Centennial Amapa |

Centennial Asset Participações Amapá S.A. | |

| CERCLA |

Comprehensive Environmental Response, Compensation and Liability Act | |

| Cockatoo Island |

Cockatoo Island Joint Venture | |

| Directors’ Plan |

1996 Nonemployee Directors’ Compensation Plan, as amended and restated 1/1/2005 | |

| Dofasco |

ArcelorMittal Dofasco Inc. | |

| EAF |

Electric arc furnace | |

| East Greenfield |

East Greenfield Investors, LLC | |

| EITF |

Emerging Issues Task Force | |

| Empire |

Empire Iron Mining Partnership | |

| EPA |

United States Environmental Protection Agency | |

| EPS |

Earnings per share | |

| FASB |

Financial Accounting Standards Board | |

| Ferrominera |

C.V.G. Ferrominera Orinoco C.A. of Venezuela | |

| FIN |

FASB Interpretation Number | |

| F.O.B. |

Free on board | |

| FSP |

FASB Staff Position | |

| GAAP |

Accounting principles generally accepted in the United States | |

| GAM |

Group Annuity Mortality | |

| HAP |

Hazardous air pollutants | |

| HBI |

Hot Briquette Iron | |

| Hibbing |

Hibbing Taconite Company | |

| ICE |

Incentive Equity Plan | |

| IRS |

Internal Revenue Service | |

| ISO |

International Standards Organization | |

| Ispat |

Ispat Inland Steel Company | |

| JORC |

Joint Ore Reserves Code | |

| Kobe Steel |

Kobe Steel, LTD. | |

| kWh |

Kilowatt hours | |

| Laiwu |

Laiwu Steel Group, Ltd. | |

| LIBOR |

London Interbank Offered Rate | |

| LIFO |

Last-in, first-out | |

| LTI |

Lost Time Injuries | |

| LTIFR |

Lost Time Injury Frequency Rate |

2

| Abbreviation or acronym |

Term | |

| LTVSMC |

LTV Steel Mining Company | |

| MACT |

Maximum Achievable Control Technology | |

| MDEQ |

Michigan Department of Environmental Quality | |

| MMBTU |

Million British Thermal Units | |

| MMX |

MMX Minerção e Metalicos S.A. | |

| MPCA |

Minnesota Pollution Control Agency | |

| MPSC |

Michigan Public Service Commission | |

| MSHA |

Mine Safety and Health Administration | |

| NBCWA |

National Bituminous Coal Wage Agreement | |

| NDEP |

Nevada Department of Environmental Protection | |

| NLRB |

National Labor Relations Board | |

| Northshore |

Northshore Mining Company | |

| NRD |

Natural Resource Damages | |

| Oak Grove |

Oak Grove Resources, LLC | |

| OPEB |

Other postretirement benefits | |

| PBO |

Projected Benefit Obligation | |

| PCB |

Polychlorinated Biphenyl | |

| Pinnacle |

Pinnacle Mining Company, LLC | |

| PinnOak |

Cliffs North American Coal LLC (f/k/a PinnOak Resources, LLC) | |

| PolyMet |

PolyMet Mining Inc. | |

| Portman |

Portman Limited | |

| PPI |

Producers Price Indices | |

| PRP |

Potentially responsible party | |

| QCoal |

QCoal Pty Ltd | |

| Renewafuel |

Renewafuel, LLC | |

| RONA |

Return on net assets | |

| RTWG |

Rio Tinto Working Group | |

| SAB |

Staff Accounting Bulletin | |

| SAR |

Stock Appreciation Rights | |

| SEC |

United States Securities and Exchange Commission | |

| Severstal |

Severstal North America, Inc. | |

| SFAS |

Statement of Financial Accounting Standards | |

| SMM |

Sonoma Mine Management | |

| Sonoma |

Sonoma Coal Project | |

| Sonoma Sales |

Sonoma Sales Pty Ltd | |

| Stelco |

Stelco Inc. | |

| Tilden |

Tilden Mining Company L.C. | |

| Tonne |

Metric ton | |

| TSR |

Total Shareholder Return | |

| UMWA |

United Mineworkers of America | |

| United Taconite |

United Taconite LLC | |

| U.S. Steel |

United States Steel Corporation | |

| USW |

United Steelworkers | |

| Vale |

Companhia Vale do Rio Doce | |

| VEBA |

Voluntary Employee Benefit Association trusts | |

| VIE |

Variable interest entity | |

| VNQDC Plan |

Voluntary Non-Qualified Deferred Compensation Plan | |

| Wabush |

Wabush Mines Joint Venture | |

| WCI |

WCI Steel Inc. | |

| Weirton |

Weirton Steel Corporation | |

| WEPCO |

Wisconsin Electric Power Company |

3

PART I

Introduction

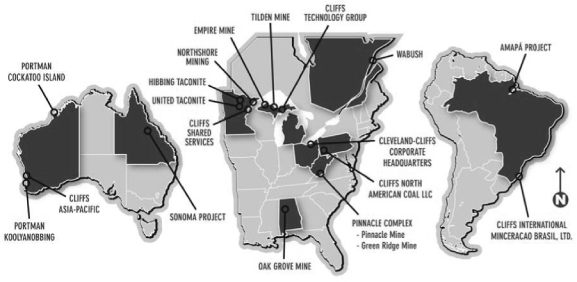

Founded in 1847, Cleveland-Cliffs is an international mining company, the largest producer of iron ore pellets in North America and a supplier of metallurgical coal to the global steelmaking industry. The Company operates six iron ore mines in Michigan, Minnesota and Eastern Canada, and three coking coal mines in West Virginia and Alabama. Cliffs also owns 80.4 percent of Portman, a large iron ore mining company in Australia, serving the Asian iron ore markets with direct-shipping fines and lump ore. In addition, the Company has a 30 percent interest in the Amapá Project, a Brazilian iron ore project, and a 45 percent economic interest in the Sonoma Project, an Australian coking and thermal coal project.

Strategic Transformation

In recent years, we have undergone a strategic transformation to an international mining company from our historic business model as a mine manager for the integrated steel industry in North America. Through a series of acquisitions and joint venture partnerships, the transformation has included our pursuit of geographic and mineral diversification, with a focus on providing raw materials to the steelmaking industry.

In April 2005, we completed the acquisition of Portman. The acquisition increased our customer base in China and Japan and established our presence in the Australian mining industry.

In March 2007, we acquired a 30 percent interest in MMX Amapá Mineração Ltda., a Brazilian limited liability company developing an iron ore project (Amapá Project). The remaining 70 percent of the Amapá Project is owned by MMX, which also serves as the manager of the Amapá Project. In January 2008, Anglo-American plc entered into a period of exclusive discussions with the controlling shareholder of MMX to purchase a controlling interest in MMX’s current 51 percent interest in the Minas-Rio iron ore project and its 70 percent interest in the Amapá Project. The proposed transaction is subject to a number of terms and conditions, including MMX board and regulatory approvals and the negotiation of definitive transaction documents. MMX will be required to obtain security holder approval for completion of the transaction.

In April 2007, we completed the acquisition of a 45 percent economic interest in Sonoma in Queensland, Australia.

In June 2007, we entered into an alliance whereby Kobe Steel agreed to license its patented ITmk3® iron-making technology to us. The alliance, which has a 10-year term, provides Cliffs a technology to convert its low-grade iron ore reserves to high-purity iron nuggets that can be used in an electric arc furnace, a market in which we do not currently compete.

In July 2007, we completed our acquisition of PinnOak, a privately-owned U.S. mining company with three high-quality, low-volatile metallurgical coal mines. The acquisition furthers our growth strategy and expands our diversification of products for the integrated steel industry.

Business Segments

In the past, we evaluated segment results based on segment operating income. As a result of the PinnOak acquisition and our focus on reducing production costs, we now evaluate segment performance based on sales margin, defined as revenues less cost of goods sold identifiable to each segment.

We are currently organized into three reportable business segments: North America Iron Ore, North American Coal and Asia-Pacific Iron Ore. Financial information about our segments is included in Item 7 and NOTE 4 — SEGMENT REPORTING — included in Item 8 of this Annual Report on Form 10-K.

4

North American Iron Ore

We are the largest producer of iron ore pellets in North America and sell virtually all of our production to integrated steel companies in the United States and Canada. We manage and operate six North American iron ore mines located in Michigan, Minnesota and Eastern Canada that currently have a rated capacity of 37 million tons of iron ore pellet production annually, representing approximately 45 percent of total North American pellet production capacity. Based on our percentage ownership of the North American mines we operate, our share of the rated pellet production capacity is currently 22.9 million tons annually, representing approximately 28 percent of total North American annual pellet capacity.

The following chart summarizes the estimated annual production capacity and percentage of total North American pellet production capacity for each of the North American iron ore pellet producers as of December 31, 2007:

North American Iron Ore Pellet

Annual Rated Capacity Tonnage

| Current Estimated Capacity (Gross Tons of Raw Ore in Millions) |

Percent of Total North American Capacity |

||||

| All Cliffs’ managed mines |

37.0 | 45.3 | % | ||

| Other U.S. mines |

|||||

| U.S. Steel’s Minnesota ore operations |

|||||

| Minnesota Taconite |

14.6 | 17.9 | |||

| Keewatin Taconite |

5.4 | 6.6 | |||

| Total U.S. Steel |

20.0 | 24.5 | |||

| ArcelorMittal USA Minorca mine |

2.9 | 3.6 | |||

| Total other U.S. mines |

22.9 | 28.1 | |||

| Other Canadian mines |

|||||

| Iron Ore Company of Canada |

12.8 | 15.7 | |||

| Quebec Cartier Mining Co. |

8.9 | 10.9 | |||

| Total other Canadian mines |

21.7 | 26.6 | |||

| Total North American mines |

81.6 | 100.0 | % | ||

We sell our share of North American iron ore production to integrated steel producers, generally pursuant to term supply agreements with various price adjustment provisions.

For the year ended December 31, 2007, we produced a total of 34.6 million tons of iron ore pellets, including 21.8 million tons for our account and 12.8 million tons on behalf of steel company owners of the mines.

We produce 13 grades of iron ore pellets, including standard, fluxed and high manganese, for use in our customers’ blast furnaces as part of the steelmaking process. The variation in grades results from the specific chemical and metallurgical properties of the ores at each mine and whether or not fluxstone is added in the process. Although the grade or grades of pellets currently delivered to each customer are based on that customer’s preferences, which depend in part on the characteristics of the customer’s blast furnace operation, in many cases our iron ore pellets can be used interchangeably. Industry demand for the various grades of iron ore pellets depends on each customer’s preferences and changes from time to time. In the event that a given mine is operating at full capacity, the terms of most of our pellet supply agreements allow some flexibility to provide our customers iron ore pellets from different mines.

Standard pellets require less processing, are generally the least costly pellets to produce and are called “standard” because no ground fluxstone (i.e., limestone, dolomite, etc.) is added to the iron ore concentrate before turning the concentrates into pellets. In the case of fluxed pellets, fluxstone is added to the concentrate,

5

which produces pellets that can perform at higher productivity levels in the customer’s specific blast furnace and will minimize the amount of fluxstone the customer may be required to add to the blast furnace. “High manganese” pellets are the pellets produced at our Canadian Wabush operation where there is more natural manganese in the crude ore than is found at our other operations. The manganese contained in the iron ore mined at Wabush cannot be entirely removed during the concentrating process. Wabush produces pellets with two levels of manganese, both in standard and fluxed grades.

It is not possible to produce pellets with identical physical and chemical properties from each of our mining and processing operations. The grade or grades of pellets purchased by and delivered to each customer are based on that customer’s preferences and availability.

Each of our North American iron ore mines are located near the Great Lakes or, in the case of Wabush, near the St. Lawrence Seaway, which is connected to the Great Lakes. The majority of our iron ore pellets are transported via railroads to loading ports for shipment via vessel to steelmakers in the U.S. or Canada.

North American Iron Ore Customers

Our North American Iron Ore revenues are derived from sales of iron ore pellets to the North American integrated steel industry, consisting of eight customers. Generally, we have multi-year supply agreements with our customers. Sales volume under these agreements is largely dependent on customer requirements, and in many cases, we are the sole supplier of iron ore pellets to the customer. Each agreement has a base price that is adjusted annually using one or more adjustment factors. Factors that can adjust price include international pellet prices, measures of general industrial inflation and steel prices. One of our supply agreements has a provision that limits the amount of price increase or decrease in any given year.

During 2007, 2006 and 2005, we sold 22.3 million, 20.4 million and 22.3 million tons of iron ore pellets, respectively, from our share of the production from our North American iron ore mines. The following five customers together accounted for a total of 83, 91 and 93 percent of North American Iron Ore Revenues from product sales and services for the years 2007, 2006 and 2005, respectively:

| Percent of Sales Revenues* |

|||||||||

| Customer |

2007 | 2006 | 2005 | ||||||

| ArcelorMittal USA |

44 | % | 44 | % | 43 | % | |||

| Algoma |

16 | 20 | 22 | ||||||

| Severstal |

10 | 13 | 12 | ||||||

| U.S. Steel Canada |

7 | 5 | 8 | ||||||

| WCI |

6 | 9 | 8 | ||||||

| Total |

83 | % | 91 | % | 93 | % | |||

| * | Excluding freight and venture partners’ cost reimbursements. |

North American Iron Ore Term Supply Agreements

Our term supply agreements in North America expire between the end of 2011 and the end of 2018. The weighted average remaining duration is seven years.

Our North American Iron Ore sales are influenced by seasonal factors in the first quarter of the year as shipments and sales are restricted by weather conditions on the Great Lakes. During the first quarter, we continue to produce our products, but we cannot ship those products via lake freighter until the Great Lakes are passable, which causes our first quarter inventory levels to rise. Our limited practice of shipping product to ports on the lower Great Lakes and/or to customers’ facilities prior to the transfer of title has somewhat mitigated the seasonal effect on first quarter inventories and sales. At both December 31, 2007 and 2006, we had approximately 0.8 million tons of pellets in inventory at lower lakes or customers’ facilities.

6

ArcelorMittal USA

On March 19, 2007, we executed an umbrella agreement with ArcelorMittal USA, a subsidiary of ArcelorMittal, that covers significant price and volume matters under three separate pre-existing iron ore pellet supply agreements for ArcelorMittal USA’s Cleveland and Indiana Harbor West, Indiana Harbor East and Weirton facilities. This umbrella agreement formalizes a previously disclosed letter agreement dated April 12, 2006.

Under terms of the umbrella agreement, some of the terms of the separate pellet sale and purchase agreements for each of the above facilities were modified to aggregate ArcelorMittal USA’s purchases during the years 2006 through 2010. The pricing provisions of the umbrella agreement are determined in accordance with the individual supply agreements that were in place for each of the facilities at the time it was executed.

During 2006 through 2010, ArcelorMittal USA is obligated to purchase specified minimum tonnages of iron ore pellets on an aggregate basis. The umbrella agreement also sets the minimum annual tonnage at ArcelorMittal USA’s approximately budgeted usage levels through 2010, with pricing based on the facility to which the pellets are delivered. Beginning in 2007, the terms of the umbrella agreement allow ArcelorMittal USA to manage its ore inventory levels through buydown provisions, which permit it to reduce its tonnage purchase obligation each year at a specified price per ton, and through deferral provisions, which permit ArcelorMittal USA to defer a portion of its annual tonnage purchase obligation beginning in 2007. ArcelorMittal USA has opted to defer the purchase of 550,000 tons from 2007 to 2008. The umbrella agreement also provides for consistent nomination procedures through 2010 across all three iron ore pellet supply agreements.

If, at the end of the umbrella agreement term in 2010, a new agreement is not executed, our pellet supply agreements with ArcelorMittal USA prior to executing the umbrella agreement will again become the basis for supplying pellets to ArcelorMittal USA:

| Facility |

Agreement runs through | |

| Cleveland Works and Indiana Harbor West facilities |

2016 | |

| Indiana Harbor East facility |

2015 | |

| Weirton facility |

2018 |

In 2005, ArcelorMittal USA shut down ArcelorMittal-Weirton’s blast furnace. The Weirton Contract had a minimum annual purchase obligation from ArcelorMittal-Weirton to purchase iron ore pellets for the years 2006 through and including 2018, with a minimum annual purchase obligation of two million tons per year. The ArcelorMittal-Weirton blast furnace has been permanently shut down and to the best of our knowledge will not be restarted. The umbrella agreement eliminated the Weirton minimum purchase obligation.

ArcelorMittal USA is a 62.3 percent equity participant in Hibbing and a 21 percent equity partner in Empire with limited rights and obligations and a 28.6 percent participant in Wabush. In 2007, 2006 and 2005 our North American Iron Ore pellet sales to ArcelorMittal USA were 10.3, 9.1, and 10.7 million tons, respectively.

Algoma

Algoma, a Canadian steelmaker, is a subsidiary of Essar Steel Holdings Limited. We have a 15-year term supply agreement under which we are Algoma’s sole supplier of iron ore pellets through 2016 (the “Algoma Agreement”). Our annual obligation is capped at four million tons with our option to supply additional pellets. Pricing under the Algoma Agreement is based on a formula which includes international pellet prices (the “Pricing Formula”). The Algoma Agreement also provides that, in certain years, either party may request a price negotiation (“Reopener Years”) if prices under the Algoma Agreement differ from a specified benchmark price. The Reopener Years are 2008, 2011, and 2014. On January 3, 2008, Algoma requested price renegotiation for 2008. We have 60 days from the date of Algoma’s request to negotiate a mutually agreed upon sales price for 2008. If, after the expiration of this negotiation period, we are unable to agree on a negotiated price for 2008, either party has the right to initiate arbitration for purposes of determining the price for 2008. The price determined in the arbitration would be effective only for 2008. Prices for 2009 and 2010 would be determined in accordance with the original terms of the Algoma Agreement. In June 2007, Essar Global Limited, through its wholly owned subsidiary Essar Steel Holdings Limited, completed its acquisition of Algoma for C$1.85 billion. We do not expect the acquisition to affect our term supply agreement with Algoma. We sold 2.9 million, 3.5 million and 3.8 million tons to Algoma in 2007, 2006 and 2005, respectively.

7

Severstal

In January 2006, we entered into an agreement whereby we are the sole supplier of iron ore pellets through 2012 to Severstal. This agreement contains certain minimum purchase requirements for certain years. We sold 3.0 million, 3.7 million and 3.6 million tons to Severstal in 2007, 2006 and 2005, respectively.

On January 5, 2008, Severstal experienced an explosion and fire on the smaller of its two operating furnaces that partially curtailed production at their North American facility. We have not determined the impact of this incident on projected 2008 iron ore shipments.

WCI

On October 14, 2004, we and WCI reached agreement (the “2004 Pellet Agreement”) for us to supply 1.4 million tons of iron ore pellets in 2005 and, in 2006 and thereafter, to supply 100 percent of WCI’s annual requirements up to a maximum of two million tons of iron ore pellets. The 2004 Pellet Agreement is for a ten-year term, which commenced on January 1, 2005.

On May 1, 2006, an entity controlled by the secured noteholders of WCI acquired the steelmaking assets and business of WCI (“New WCI”). New WCI assumed the 2004 Pellet Agreement. We sold 1.5 million, 1.6 million and 1.4 million tons to New WCI in 2007, 2006 and 2005, respectively.

U.S. Steel Canada

U.S. Steel Canada (formerly Stelco) is a 44.6 percent participant in Wabush, and U.S. subsidiaries of U.S. Steel Canada own 14.7 percent of Hibbing and 15 percent of Tilden.

In December 2006, we executed a binding pellet supply term sheet with U.S. Steel Canada with respect to a seven-year supply agreement to provide their Lake Erie Steel and Hamilton Steel facilities excess pellet requirements above the amount supplied from their ownership interest at Hibbing, Tilden and Wabush. Pellet sales to U.S. Steel Canada totaled 1.2 million, 0.9 million and 1.4 million tons in 2007, 2006 and 2005, respectively.

North American Coal

Cliffs is a supplier of metallurgical coal in North America. We own and operate three North American coal mines located in West Virginia and Alabama that currently have a rated capacity of 6.5 million short tons of production annually. For the five months ended December 31, 2007, we sold a total of 1.2 million tons.

All three of our North American coal mines are positioned near rail or barge lines providing access to international shipping ports, which allows for export of our coal production.

North American Coal Customers

North American Coal’s production is sold to global integrated steel and coke producers in Europe, South America and North America. Approximately 90 percent of our 2008 production is committed under one-year contracts. Customer contracts in North America typically are negotiated on a calendar year basis with international contracts negotiated as of March 31.

Exports and domestic sales represented 66 percent and 34 percent, respectively, of our North American Coal sales in 2007. No customer comprised more than 10 percent of our consolidated sales.

Asia-Pacific Iron Ore

Our Asia-Pacific Iron Ore segment is comprised of Portman, an Australian iron ore mining company. The minority interest ownership of the company is publicly held and traded on the Australian Stock Exchange under the ticker symbol “PMM”.

Portman’s operations are in Western Australia and include its 100 percent owned Koolyanobbing mine and its 50 percent equity interest in Cockatoo Island. Portman serves the Asian iron ore markets with direct-shipping fines and lump ore. Production in 2007 (excluding its 0.7 million tonne share of Cockatoo Island) was 7.7 million tonnes.

8

These two operations supply a total of four direct shipping export products to Asia via the global seaborne trade market. Koolyanobbing produces a standard lump and fines product as well as low grade fines product. Cockatoo Island produces and exports a single premium fines product. Portman lump products are directly charged to the blast furnace, while the fines products are used as sinter feed. The variation in Portman’s four export product grades reflects the inherent chemical and physical characteristics of the ore bodies mined as well as the supply requirements of the customers.

Koolyanobbing is a collective term for the operating deposits at Koolyanobbing, Mount Jackson and Windarling. The project is located 425 kilometers east of Perth and approximately 50 kilometers northeast of the town of Southern Cross. There are approximately 100 kilometers separating the three mining areas. Banded iron formation hosts the mineralization which is predominately hematite and goethite. Each deposit is characterized with different chemical and physical attributes and in order to achieve customer product quality; ore in varying quantities from each deposit must be blended together.

Blending is undertaken at Koolyanobbing, where the crushing and screening plant is located. Standard and low grade products are produced in separate campaigns. Once the blended ore has been crushed and screened into a direct shipping product, it is transported by rail approximately 575 kilometers south to the Port of Esperance for shipment to Asian customers.

Cockatoo Island is located off the Kimberley coast of Western Australia, approximately 1,900 kilometers north of Perth and is only accessible by sea and air. Cockatoo Island produces a single high iron product known as Cockatoo Island Premium Fines. The deposit is almost pure hematite and contains very few contaminants enabling the shipping grade to be above 68 percent iron. Ore is mined below the sea level on the southern edge of the island. This is facilitated by a sea wall which enables mining to a depth of 40 meters below sea level. Ore is crushed and screened to the final product sizing. Vessels berth at the island and the fines product is loaded directly to the ship. Cockatoo Island Premium Fines are highly sought in the global marketplace due to its extremely high iron grade and low valueless mineral content. Production at Cockatoo Island is expected to continue into the second quarter of 2008, with shipments to end in the third quarter of 2008.

Asia-Pacific Iron Ore Customers

Portman’s production is fully committed to steel companies in China and Japan through 2012. A limited spot market exists for seaborne iron ore as most production is sold under long-term contracts with annual benchmark prices driven from negotiations between the major suppliers and Chinese, Japanese and other Asian steel mills. The three major iron ore producers, Vale, Rio Tinto and BHP, dominate the seaborne iron ore trade and together account for approximately three-quarters of the global supply to the seaborne market.

Portman has long-term supply agreements with steel producers in China and Japan that account for approximately 74 percent and 26 percent, respectively, of sales. Sales volume under the agreements is partially dependent on customer requirements. Each agreement is priced based on benchmark pricing established for Australian producers.

During 2007, 2006 and 2005, we sold 8.1 million, 7.4 million and 4.9 million tonnes of iron ore, respectively, from our Western Australia mines. (Sales for 2005 represent amounts since the March 31, 2005 acquisition of Portman).

Sales in 2007 were to 17 Chinese and three Japanese customers. No customer comprised more than 15 percent of Asia-Pacific Iron Ore sales or 10 percent of our consolidated sales in 2007, 2006 or 2005. Portman’s five largest customers accounted for approximately 47 percent of Portman’s sales in 2007, 46 percent in 2006 and 50 percent in 2005.

Investments

In addition to the Company’s reportable business segments, we are partner to a number of projects, including the Amapá Iron Ore Project in Brazil and the Sonoma Coal Project in Australia.

9

Amapá

We are a 30 percent minority interest owner in the Amapá Project which consists of a significant iron ore deposit, a 192-kilometer railway connecting the mine location to an existing port facility and 71 hectares of real estate on the banks of the Amazon River, reserved for a loading terminal. The Amapá Project initiated production in late-December 2007. It is expected that completion of the construction of the concentrator and ramp-up of production will occur in 2008. It is estimated that Amapá will produce and sell between three and four million tonnes of iron ore fines products in 2008 and 6.5 million tonnes annually once fully operational. The majority of Amapá’s production is committed under a long-term supply agreement with an operator of an iron oxide pelletizing plant in the Kingdom of Bahrain.

Sonoma

We are a 45 percent economic interest owner in the Sonoma Coal Project in Queensland, Australia. The project is currently operating and expected to produce approximately two million tonnes of coal in 2008 and three to four million tonnes of coal annually in 2009 and beyond. Production will include a mix of hard coking coal and thermal coal. The Sonoma Coal Project has economically recoverable reserves of 27 million tonnes. All 2008 production is committed under supply agreements with customers in Asia.

The Iron Ore, Metallurgical Coal and Steel Industries

Almost all iron ore and metallurgical coal is used in steelmaking and therefore is dependent on the steel industry. Global crude steel production broke the 100 million tonne per month level for the first time in March 2006. Production in 2007 for the 67 countries reporting to the International Iron and Steel Institute increased approximately seven percent over 2006. The growing level of international production is largely due to the rapid industrial growth in China.

China produced 489 million tonnes of crude steel in 2007, up 15 percent over 2006, accounting for approximately 37 percent of global production.

The rapid growth in steel production in China has only been partially met by a corresponding increase in domestic Chinese iron ore production. Chinese iron ore deposits, although substantial, are of a lower grade (less than half of the equivalent iron ore content) than the current iron ore supplied from Brazil and Australia.

The world price of iron ore is influenced by international demand. The rapid growth in Chinese demand, particularly in more recent years, has created a market imbalance and has led to demand outstripping supply. This market imbalance has recently led to high spot prices for natural iron ore and increases of 9.5 percent, 19 percent and 71.5 percent in 2007, 2006 and 2005, respectively, in benchmark prices for Brazilian and Australian suppliers of iron ore. In mid-February 2008, Japan’s Nippon Steel and South Korea’s Posco agreed with Vale to a 65 percent increase in the price for fines. The increased demand for iron ore has resulted in the major iron ore suppliers expanding efforts to increase their capacity.

Competition

We compete with several iron ore producers in North America, including Iron Ore Company of Canada, Quebec Cartier Mining Company and U.S. Steel, as well as other steel companies that own interests in iron ore mines that may have excess iron ore inventories. In the coal industry, we compete with many metallurgical coal producers including Alpha Natural Resources, Massey Energy, Jim Walter Resources, Peabody Energy, CONSOL and others.

As the North American steel industry continues to consolidate, a major focus of the consolidation is on the continued life of the integrated steel industry’s raw steelmaking operations (i.e., blast furnaces and basic oxygen furnaces that produce raw steel). In addition, other competitive forces have become a large factor in the iron ore business. Electric furnaces built by mini-mills, which are steel recyclers, generally produce steel by using scrap steel and reduced-iron products, not iron ore pellets, in their electric furnaces.

Competition among the sellers of iron ore pellets and metallurgical coal is predicated upon the usual competitive factors of price, availability of supply, product performance, service and transportation cost to the consumer.

10

Portman exports iron ore products to China and Japan in the world seaborne trade. Portman competes with major iron ore exporters from Australia, Brazil and India.

Environment

General

Various governmental bodies are continually promulgating new laws and regulations affecting us, our customers, and our suppliers in many areas, including waste discharge and disposal, hazardous classification of materials and products, air and water discharges, and many other environmental, health, and safety matters. Although we believe that our environmental policies and practices are sound and do not expect that the application of any current laws or regulations would reasonably be expected to result in a material adverse effect on our business or financial condition, we cannot predict the collective adverse impact of the expanding body of laws and regulations.

Specifically, proposals for voluntary initiatives and mandatory controls are being discussed both in the United States and worldwide to reduce greenhouse gases — most notably carbon dioxide, a by-product of burning fossil fuels and other industrial processes. Although the outcome of these efforts remains uncertain, we have proactively engaged outside experts to more formally develop a comprehensive, enterprise-wide greenhouse gas management strategy. The comprehensive strategy is aimed at considering all significant aspects associated with greenhouse gas initiatives and optimizing our regulatory, operational, and financial impacts and/or opportunities. We will continue to monitor developments related to efforts to register and potentially regulate greenhouse gas emissions.

North American Iron Ore

In the construction of our facilities and in their operation, substantial costs have been incurred and will continue to be incurred to avoid undue effect on the environment. Our North American capital expenditures relating to environmental matters were $8.8 million, $10.5 million, and $9.2 million in 2007, 2006 and 2005, respectively. It is estimated that approximately $10.8 million will be spent in 2008 for capital environmental control facilities.

The iron ore industry has been identified by the EPA as an industrial category that emits pollutants established by the 1990 Clean Air Act Amendments. These pollutants included over 200 substances that are now classified as HAP. The EPA is required to develop rules that would require major sources of HAP to utilize MACT standards for their emissions. Pursuant to this statutory requirement, the EPA published a final rule on October 30, 2003 imposing emission limitations and other requirements on taconite iron ore processing operations. On December 15, 2005, we and Ispat-Inland Mining Company filed a Petition to Delete as a source category regulated by Section 112 of the Clean Air Act. The EPA requested additional information, and a supplement was submitted to the EPA on August 22, 2006. A response is pending.

On March 10, 2005, the EPA issued the Clean Air Interstate Rule final regulations and on March 15, 2005, the EPA issued the Clean Air Mercury Rule. The rules establish phased reductions of NOx, SO2 and mercury from electric power generating stations. Accordingly, Cliffs anticipates that it will incur capital and ongoing emission allowance costs at its Silver Bay Power Plant to maintain compliance with the rule. As Cliffs is still optimizing its various options for compliance, we cannot accurately estimate the timing or cost of emission controls at this time.

On December 16, 2006, we submitted an administrative permit amendment application to the MPCA with respect to Northshore’s Title V operating permit. The proposed amendment requested the deletion of a 30-year old “control city” monitoring requirement which was used to assess the adequacy of air emission control equipment installed in the 1970s. MPCA had discontinued use of control city monitoring in the early 1980s, but had recently reinstituted monitoring. The control city monitoring compared ambient fiber levels in St. Paul, Minnesota to levels at Northshore and the surrounding area. The administrative permit amendment application argued that the control city monitoring requirement is an obsolete and redundant standard given Northshore’s existing emission control equipment and applicable federal regulations, state rules, and permit requirements.

11

We received a letter dated February 23, 2007 from the MPCA notifying us that our proposed permit amendment had been denied. We have appealed the denial to the Minnesota Court of Appeals. Subsequent to the filing of our appeal, the MPCA advised Northshore that the MPCA considered Northshore to be in violation of the control city standard. In addition, the Minnesota Center for Environmental Advocacy intervened in our appeal of the denial of a proposed permit amendment to our Title V operating permit. Oral arguments on our appeal were held on February 21, 2008.

If either our appeal is unsuccessful or if we are unable to negotiate an acceptable compliance schedule, Northshore could be subject to future enforcement actions with respect to its Title V operating permit if we are unable to meet the permit requirements as interpreted by MPCA.

North American Coal

In 1996 and 1997, two cases were brought alleging that dust from the Concord Preparation Plant damaged properties in the area. In 2002, the parties entered into settlement agreements with the former owner in exchange for a lump sum payment and the agreement to implement remedial measures. However, the plaintiffs were not required to dismiss their claims. PinnOak was added to these cases in 2004 and 2006. The plaintiffs in these matters are now seeking additional remediation measures and we are opposing this assertion and believe that any amounts ultimately paid in this matter will not be material. In addition to the two cases noted above, in 2004 approximately 160 individual plaintiffs brought an action against PinnOak asserting injuries arising from particulate emissions from the Concord Preparation Plant. PinnOak is seeking a summary judgment in this most recent matter because it had previously been concluded under the 2002 settlement agreement.

In 2006, 13 plaintiffs brought an action against PinnOak related to the operation of the Concord Preparation Plant. These plaintiffs assert that dangerous levels of coal dust emissions have been allowed to accumulate at that facility. We deny this allegation and are defending the matter vigorously.

Since the acquisition of the PinnOak properties in 2007, we are evaluating ways to improve the efficiency and reduce the environmental impact of our coal operations. Included in these evaluations are ways to reduce refuse and air emissions from preparation plants and maintaining the quality of water in and around our properties.

Asia-Pacific Iron Ore

Environmental issues and their management continued to be an important focus at our Asia-Pacific iron ore operations throughout 2007. Mining operations proceeded without major environmental incidents. Implementation of management controls at the Koolyanobbing operations continued, and a significant milestone was achieved with the certification of the environmental management system to the international standard ISO 14001.

A third-party compliance review of the Koolyanobbing operations was undertaken during 2007. The Koolyanobbing operations are among the most heavily regulated mining operations in Western Australia, with environmental conditions set at both State and Federal government levels. The review audited compliance with over 200 regulatory conditions and management plan commitments. A high level of compliance was achieved across all areas. Nine items of non-compliance were reported, with most being non-material in terms of environmental risk. Work commenced to address these items, including improved blasting procedures, the initiation of a project to quantify dust emission sources and the inclusion of soil assessment protocols in waste dump planning.

The Asia-Pacific iron ore environmental team was strengthened during the year to ensure that both the current mine operations continue to be well managed and that expansion plans receive timely environmental assessment and approvals.

12

We commenced a major environmental permitting program at the Koolyanobbing operations in 2007 in preparation of the submission of approval applications for a number of development proposals in 2008. The program included environmental baseline and impact assessment for expansion of pits and waste dumps at Koolyanobbing, Mount Jackson and Windarling. Groundwater studies, including a ground water re-injection trial, were completed in support of an approval application for mining below the water table at Windarling.

In May 2007, the AEPA released a report outlining the recommendations for a significant extension of the conservation estate in the area of the Koolyanobbing mining operations. The AEPA report recommended the conversion of much of the area to Class A conservation reserve, which effectively excludes mining activities. The report represents the view of the AEPA and neither creates an obligation on the government to act nor affects the rights of Portman to operate under existing approvals. However, if implemented, the AEPA recommendations would severely constrain Portman’s expansion opportunities in the vicinity of the current operations. There are disparate views within government agencies over the issue. We have communicated our concerns to the government in a manner that indicates a willingness to work with all parties to achieve a sustainable outcome for conservation and resource development in the region.

At the Cockatoo Island operations, the focus of environmental work was on preparing a submission for environmental approvals for extension of the embankment mining project. A submission was lodged with the regulatory agencies in December 2007, with the aim of securing approvals by mid-2008. Work continued on refining a closure plan for the Cockatoo Island operations. A program of rehabilitation for the areas that do not form part of the active mining area adjacent to the seawall is planned for 2008.

For additional information on our environmental matters, see Item 3. Legal Proceedings and NOTE 5 — ENVIRONMENTAL AND MINE CLOSURE OBLIGATIONS in Item 8.

Energy

Electricity. The Empire and Tilden mines receive electric power from WEPCO. Under the contracts, Empire and Tilden were afforded an energy price cap and certain power curtailment features. These contracts terminated at the end of the 2007 calendar year. Prior to the termination of the contracts in 2007, WEPCO initiated a tariff rate case in which Empire and Tilden participated in order to establish a new tariff rate for each mine upon the termination of the contracts. The resulting settlement, which was approved by the Michigan Public Service Commission, created a new industrial tariff rate. Effective January 1, 2008 Tilden and Empire receive their electrical power from WEPCO under the new tariff rate. On January 31, 2008, WEPCO filed a new rate case, proposing an increase to the tariff rates that became effective on January 1, 2008. In February 2008, we filed a petition to intervene in the new rate case. We are also reviewing the rate case and analyzing the potential impact on Empire and Tilden.

Electric power for the Hibbing mine and the United Taconite mine is supplied by Minnesota Power, Inc., under agreements that continue to December 2008 and October 2008, respectively.

Silver Bay Power Company, an indirect wholly owned subsidiary of ours, with a 115 megawatt power plant, provides the majority of Northshore’s energy requirements, has an interconnection agreement with Minnesota Power, Inc. for backup power, and sells 40 megawatts of excess power capacity to Northern States Power Company under a contract that extends to 2011.

Wabush owns a portion of the Twin Falls Hydro Generation facility that provides power for Wabush’s mining operations in Newfoundland. We have a 20-year agreement with Newfoundland Power, which continues until December 31, 2014. This agreement allows an interchange of water rights in return for the power needs for Wabush’s mining operations. The Wabush pelletizing operations in Quebec are served by Quebec Hydro on an annual contract.

The Oak Grove mine and Concord Preparation Plant are supplied electrical power by Alabama Power, a Southern Company, under a contract which expires June 30, 2008. Rates of the contract are subject to change during the term of the contract as regulated by the Alabama Public Service Commission.

13

Electrical power to the Pinnacle, Green Ridge No. 1, Green Ridge No. 2 mines and the Pinnacle Preparation Plant are supplied by the Appalachian Power Company under two contracts. The Indian Creek contract is renewable September 22, 2008 and the Pinnacle Creek contract is renewable July 4, 2008. Both contracts specify the applicable rate schedule, minimum monthly charge and power capacity furnished. Rates, terms and conditions of the contracts are subject to the approval of the Public Service Commission of West Virginia.

Koolyanobbing and its associated satellite mines draw power from independent diesel fueled power stations and generators. Temporary diesel power generation capacity has been installed at the Koolyanobbing operations, allowing sufficient time for a detailed investigation into the viability of long-term options such as connecting into the Western Australian South West Interconnected System or provision of natural gas or dual fuel (natural gas and diesel) generating capacity. These options are not economic for the satellite mines, which will continue being powered by diesel generators.

Electrical supply on Cockatoo Island is diesel generated. The powerhouse adjacent to the processing plant powers the shiploader, fuel farm and the processing plant. The workshop and administration office is powered by a separate generator.

Sonoma receives its electricity from the public grid generated by local electric retailer Ergon Energy. In 2008, Sonoma plans to go to the contestable energy market and invite offers to supply electricity on a long-term basis. The state of Queensland enjoys a competitive deregulated energy market.

Process Fuel. We have contracts providing for the transport of natural gas for our United States iron ore operations. The Empire and Tilden mines have the capability of burning natural gas, coal, or to a lesser extent, oil. The Hibbing and Northshore mines have the capability to burn natural gas and oil. The United Taconite mine has the ability to burn coal, natural gas and coke breeze. Although all of the U.S. iron ore mines have the capability of burning natural gas, with higher natural gas prices, the pelletizing operations for the U.S. iron ore mines utilize alternate fuels when practicable. Wabush has the capability to burn oil and coke breeze.

Research and Development

We have been a leader in iron ore mining technology for more than 160 years. We operated some of the first mines on Michigan’s Marquette Iron Range and pioneered early open-pit and underground mining methods. From the first application of electrical power in Michigan’s underground mines to the use today of sophisticated computers and global positioning satellite systems, we have been leaders in the application of new technology to the centuries-old business of mineral extraction. Today, our engineering and technical staffs are engaged in full-time technical support of our operations and improvement of existing products.

As part of our efforts to develop alternative metallic products, we are developing, with Kobe Steel, a commercial-scale reduced iron plant, which will convert taconite into nearly pure iron in nugget form utilizing Kobe Steel’s ITmk3® technology. This innovative technology has the potential to open new markets by offering an economically competitive supply of iron material for electric arc furnaces.

North American Coal and Asia-Pacific Iron Ore do not have any material research and development projects.

Employees

As of December 31, 2007, there were a total of 5,298 employees:

| North American Iron Ore |

North American Coal |

Asia-Pacific Iron Ore |

Corporate & Support Services |

Total | ||||||

| Salaried |

843 | 190 | 77 | 211 | 1,321 | |||||

| Hourly |

3,264 | 701 | 12 | — | 3,977 | |||||

| Total (1) |

4,107 | 891 | 89 | 211 | 5,298 | |||||

| (1) | Includes our employees and the employees of the North American joint ventures. |

14

Hourly employees at our Michigan and Minnesota iron ore mining operations (other than Northshore) are represented by the USW under collective bargaining agreements dated August 1, 2004 that expire on September 1, 2008. Bargaining for new collective agreements will take place in 2008. Both the U.S. Steel and ArcelorMittal USA collective bargaining agreements with the USW also expire on September 1, 2008. The current profitable state of both the North American steel and iron ore industries has been cited by the USW as an important factor in developing negotiation objectives for 2008.

In April 2006, the USW advised us with a “Written Notification” that it was initiating an organizing campaign at Northshore. Under the terms of our collective bargaining agreements with the USW, we are required to remain neutral during the organizing campaign. Based upon subsequent conversations with USW representatives, the organizing campaign was postponed pending resolution of issues related to the neutrality commitment in the collective bargaining agreement.

Hourly employees at Wabush are represented by the USW. Wabush and the USW entered into a collective bargaining agreement in October 2004 that expires on March 1, 2009.

In July 2007, the Company purchased PinnOak. Hourly production and maintenance employees at its subsidiary corporations are represented by the UMWA. Each of those subsidiary companies entered into new collective bargaining agreements with the UMWA in March 2007 that expire on December 31, 2011. Those collective agreements are identical in all material respects to the National Bituminous Coal Wage Agreement of 2007 between the UMWA and the Bituminous Coal Operators’ Association.

Our employees at Asia-Pacific operations are not represented under collective bargaining agreements.

As of the end of 2007, 56 percent of our employees are covered by collective bargaining agreements. Agreements covering 72 percent of those employees expire by the end of 2008.

Growth Strategy

We expect to grow our business and presence as an international mining company by expanding both geographically and through the minerals that we mine and market. Recent investments in Australia and Latin America, as well as acquisitions in minerals outside of iron ore, such as coal, illustrate the execution of this strategy.

Mineral Diversification — In addition to continuously evaluating acquisition targets and investment opportunities in iron ore, metallurgical and thermal coal, we also consider opportunities outside of these areas that could expand our position as a supplier of raw materials to the steelmaking industry.

Geographic Diversification — We currently have producing assets in North America and Western Australia. Through recent growth projects such as the Amapá Project, which provides entry into Latin America, and Sonoma in Eastern Australia, we are increasing our presence in markets outside of North America.

Our strategy also includes plans to capitalize on our unique technological expertise in the area of concentrating and processing lower-grade ores into high-quality products. Illustrating this strategy is our recently announced alliance to license Kobe Steel’s patented ITmk3® iron-making technology. This technology provides a means to use our existing iron ore reserves as a raw material to produce high-purity iron nuggets containing more than 96 percent iron. These iron nuggets are a high-quality, marketable raw material for EAFs, a growing segment of the steel industry we do not currently supply.

Much of the current increase in global demand for steel is due to industrialization in countries such as China. China is seeking foreign supplies of the raw materials it needs to produce steel to build infrastructure, factories, hotels and other buildings and to manufacture motor vehicles and appliances. Currently, China is the world’s largest steel producer, with 37 percent of global steel production, and China’s steel production is expected to continue to grow. Chinese iron ore imports rose approximately 19 percent in 2007 and are expected to further increase in 2008. China is the largest consumer of iron ore, steel and copper. We are attempting to capitalize on China’s industrial growth by acquiring well-located iron ore and/or metallurgical coal properties and obtaining agreements to supply iron ore and coal to international steel producers.

15

Available Information

Our headquarters are located at 1100 Superior Avenue, Cleveland, Ohio 44114-2544, and our telephone number is (216) 694-5700. We are subject to the reporting requirements of the Securities Exchange Act of 1934 (the “Exchange Act”) and its rules and regulations. The Exchange Act requires us to file reports, proxy statements and other information with the SEC. Copies of these reports and other information can be read and copied at:

SEC Public Reference Room

100 F Street N.E.

Washington, D.C. 20549

Information on the operation of the Public Reference Room may be obtained by calling the SEC at 1-800-SEC-0330.

The SEC maintains a website that contains reports, proxy statements and other information regarding issuers that file electronically with the SEC. These materials may be obtained electronically by accessing the SEC’s home page at http://www.sec.gov.

We make available, free of charge on our website, our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and amendments to these reports filed or furnished pursuant to Section 13(a) or 15(d) of the Exchange Act, as soon as reasonably practicable after we electronically file these documents with, or furnish them to, the SEC. These documents are posted on our website at www.cleveland-cliffs.com — under “For Investors”.

We also make available, free of charge on our website, the charter of the Audit Committee, Board Affairs Committee, Compensation and Organization Committee and Finance Committee as well as the Corporate Governance Guidelines and the Code of Business Conduct & Ethics adopted by our Board of Directors. These documents are posted on our website at www.cleveland-cliffs.com — under “For Investors”, select the “Corporate Governance” link.

References to our website do not constitute incorporation by reference of the information contained on our website and such information is not part of this Form 10-K.

Copies of the above referenced information will also be made available, free of charge, by calling (216) 694-5700 or upon written request to:

Cleveland-Cliffs Inc

Investor Relations

1100 Superior Avenue

Cleveland, OH 44114-2544

16

If the rate of steel consumption slows globally, it could lead to excess global capacity, increasing competition within the steel industry and increased imports into the United States, potentially lowering the demand for iron ore and coal.

The world price of iron ore and coal are strongly influenced by international demand. The current growing level of international demand for raw materials for steel production is largely due to the rapid industrial growth in China. If the economic growth rate in China slows, which may be difficult to forecast, less steel may be used in construction and manufacturing, which could decrease demand for iron ore and coal. This could adversely impact the world iron ore and coal markets and our operations. A slowing of the economic growth rate globally leading to overcapacity in the steelmaking industry could also result in greater exports of steel out of Eastern Europe, Asia and Latin America, which, if imported into North America, could decrease demand for domestically produced steel, thereby decreasing the demand for iron ore and coal supplied in North America. During 2006, China became the world’s largest exporter of steel.

China’s domestic crude steel production climbed approximately 17 percent in 2007 as compared to 2006. Based on the American Iron and Steel Institute’s Apparent Steel Supply (excluding semi-finished steel products), imports of steel into the United States constituted 23.3 percent, 27.3 percent and 21.3 percent of the domestic steel market supply for 2007, 2006 and 2005, respectively. Further, production of steel by North American integrated steel manufacturers may also be replaced, to some extent, by production of substitute materials by other manufacturers. In the case of some product applications, North American steel manufacturers compete with manufacturers of other materials, including plastic, aluminum, graphite composites, ceramics, glass, wood and concrete. Most of our term supply agreements for the sale of iron ore products are requirements-based or provide for flexibility of volume above a minimum level. Reduced demand for and consumption of iron ore products by integrated steel producers have had and may continue to have a significant negative impact on our sales, margins and profitability.

Capacity expansions within the industry could lead to lower global iron ore and coal prices or impact our production.

The increased demand for iron ore and coal, particularly from China, has resulted in the major iron ore and metallurgic coal suppliers increasing their capacity. Many of our competitors have announced plans to increase their capacity through capital expenditures, project expansion and acquisitions to capitalize on these opportunities. An increase in our competitors’ capacity could result in excess supply of iron ore and coal, resulting in downward pressure on prices. A decrease in pricing would adversely impact our sales, margins and profitability.

If steelmakers use methods other than blast furnace production to produce steel, or if their blast furnaces shut down or otherwise reduce production, the demand for our iron ore and coal products may decrease.

Demand for our iron ore and coal products is determined by the operating rates for the blast furnaces of steel companies. However, not all finished steel is produced by blast furnaces; finished steel also may be produced by other methods that do not require iron ore products. For example, steel “mini-mills,” which are steel recyclers, generally produce steel primarily by using scrap steel and other iron products, not iron ore pellets, in their electric furnaces. Production of steel by steel mini-mills was approximately 60 percent of North American total finished steel production in 2007. Steel producers also can produce steel using imported iron ore or semi-finished steel products, which eliminates the need for domestic iron ore. Environmental restrictions on the use of blast furnaces also may reduce our customers’ use of their blast furnaces. Maintenance of blast furnaces can require substantial capital expenditures. Our customers may choose not to maintain their blast furnaces, and some of our customers may not have the resources necessary to adequately maintain their blast furnaces. If our customers use methods to produce steel that do not use iron ore and coal products, demand for our iron ore and coal products will decrease, which could adversely affect our sales, margins and profitability.

17

A substantial majority of our sales are made under term supply agreements, which are important to the stability and profitability of our operations.

In 2007, more than 95 percent of our North American Iron Ore sales volume, the majority of our North American Coal sales, and virtually all of our Australian sales were sold under term supply agreements. For North American Coal, these agreements typically cover a twelve-month period and must be renewed each year. The Asia-Pacific Iron Ore contracts expire in 2010. We cannot be certain that we will be able to renew or replace existing term supply agreements at the same volume levels, prices or with similar profit margins when they expire. A loss of sales to our existing customers could have a substantial negative impact on our sales, margins and profitability.

Our North American Iron Ore term supply agreements contain a number of price adjustment provisions, or price escalators, including adjustments based on general industrial inflation rates, the price of steel and the international price of iron ore pellets, among other factors, that allow us to adjust the prices under those agreements generally on an annual basis. Our price adjustment provisions are weighted and some are subject to annual collars, which limit our ability to raise prices to match international levels and fully capitalize on strong demand for iron ore. Most of our North American Iron Ore term supply agreements do not otherwise allow us to increase our prices and to directly pass through higher production costs to our customers. An inability to increase prices or pass along increased costs could adversely affect our margins and profitability.

In North America, we depend on a limited number of customers.

Five customers together accounted for more than 80 percent of our North American Iron Ore sales revenues measured as a percent of product revenues for each of the past three years. If one or more of these customers were to significantly reduce their purchases of products from us, or if we were unable to sell products to them on terms as favorable to us as the terms under our current term supply agreements, our North American sales, margins and profitability could suffer materially due to the high level of fixed costs and the high costs to idle or close mines. The majority of the iron ore we manage and produce is for our own account, and therefore we rely on sales to our joint venture partners and other third-party customers for most of our revenues.

Mine closures entail substantial costs, and if we close one or more of our mines sooner than anticipated, our results of operations and financial condition may be significantly and adversely affected.

If we close any of our mines, our revenues would be reduced unless we were able to increase production at our other mines, which may not be possible. The closure of a mining operation involves significant fixed closure costs, including accelerated employment legacy costs, severance-related obligations, reclamation and other environmental costs, and the costs of terminating long-term obligations, including energy contracts and equipment leases. We base our assumptions regarding the life of our mines on detailed studies we perform from time to time, but those studies and assumptions are subject to uncertainties and estimates that may not be accurate. We recognize the costs of reclaiming open pits and shafts, stockpiles, tailings ponds, roads and other mining support areas based on the estimated mining life of our property. If we were to significantly reduce the estimated life of any of our mines, the mine-closure costs would be applied to a shorter period of production, which would increase production costs per ton produced and could significantly and adversely affect our results of operations and financial condition.

A North American mine permanent closure could significantly increase and accelerate employment legacy costs, including our expense and funding costs for pension and other postretirement benefit obligations. A number of employees would be eligible for immediate retirement under special eligibility rules that apply upon a mine closure. All employees eligible for immediate retirement under the pension plans at the time of the permanent mine closure also would be eligible for postretirement health and life insurance benefits, thereby accelerating our obligation to provide these benefits. Certain mine closures would precipitate a pension closure liability significantly greater than an ongoing operation liability. Finally, a permanent mine closure could trigger severance-related obligations, which can equal up to eight weeks of pay per employee, depending on length of service. No employee entitled to an immediate pension upon closure of a mine is entitled to severance. As a result, the closure of one or more of our mines could adversely affect our financial condition and results of operations.

18

The Cockatoo Island operation in Australia is scheduled to close in the second quarter of 2008 and plans are in process to obtain all required governmental approvals. Since all of the employees are contractors, the cost of mine closure is significantly lower in Australia than in North America. Performance bonds are in place covering the estimated closure costs.

We rely on estimates of our recoverable reserves, which is complex due to geological characteristics of the properties and the number of assumptions made.

We regularly evaluate our North American iron ore and coal reserves based on revenues and costs and update them as required in accordance with SEC Industry Guide 7. Portman and Sonoma have published reserves which follow JORC in Australia, which is similar to United States requirements. Changes to the reserve value to make them comply with SEC requirements have been made. There are numerous uncertainties inherent in estimating quantities of reserves of our mines, many of which have been in operation for several decades, including many factors beyond our control.

Estimates of reserves and future net cash flows necessarily depend upon a number of variable factors and assumptions, such as production capacity, effects of regulations by governmental agencies, future prices for iron ore and coal, future industry conditions and operating costs, severance and excise taxes, development costs and costs of extraction and reclamation, all of which may in fact vary considerably from actual results. For these reasons, estimates of the economically recoverable quantities of mineralized deposits attributable to any particular group of properties, classifications of such reserves based on risk of recovery and estimates of future net cash flows prepared by different engineers or by the same engineers at different times may vary substantially as the criteria change. Estimated ore and coal reserves could be affected by future industry conditions, geological conditions and ongoing mine planning. Actual production, revenues and expenditures with respect to our reserves will likely vary from estimates, and if such variances are material, our sales and profitability could be adversely affected.

A defect in the title or the loss of a leasehold interest in certain property could limit our ability to mine our reserves or result in significant unanticipated costs.

We conduct a significant part of our mining operations on property that we lease. A title defect or the loss of a lease could adversely affect our ability to mine the associated reserves. As such, the title to property that we intend to lease or reserves that we intend to mine may contain defects prohibiting our ability to conduct mining operations. In order to conduct our mining operations on properties where these defects exist, we may incur unanticipated costs. In addition, some leases require us to pay minimum royalties. Our inability to satisfy those requirements may cause the leasehold interest to terminate.

We rely on our joint venture partners in our mines to meet their payment obligations.

We co-own five of our six North American mines with various joint venture partners that are integrated steel producers or their subsidiaries, including ArcelorMittal USA, Laiwu and U.S. Steel Canada. While we are the manager of each of the mines we co-own, we rely on our joint venture partners to make their required capital contributions and to pay for their share of the iron ore pellets that we produce. Most of our venture partners are also our customers. If one or more of our venture partners fail to perform their obligations, the remaining venturers, including ourselves, may be required to assume additional material obligations, including significant pension and postretirement health and life insurance benefit obligations. The premature closure of a mine due to the failure of a joint venture partner to perform its obligations could result in significant fixed mine-closure costs, including severance, employment legacy costs and other employment costs, reclamation and other environmental costs, and the costs of terminating long-term obligations, including energy contracts and equipment leases.

Our expenditures for postretirement benefit and pension obligations could be materially higher than we have predicted if our underlying assumptions prove to be incorrect, if there are mine closures or our joint venture partners fail to perform their obligations that relate to employee pension plans.

We provide defined benefit pension plans and OPEB benefits to eligible union and non-union employees, including our share of expense and funding obligations with respect to unconsolidated ventures. Our pension expense and our required contributions to our pension plans are directly affected by the value of plan assets, the projected and actual rate of return on plan assets and the actuarial assumptions we use to measure our defined benefit pension plan obligations, including the rate at which future obligations are discounted.

19

We cannot predict whether changing market or economic conditions, regulatory changes or other factors will increase our pension expenses or our funding obligations, diverting funds we would otherwise apply to other uses.

We have calculated our unfunded OPEB obligation based on a number of assumptions. Discount rate, return on plan assets, and mortality assumptions parallel those utilized for pensions. If our assumptions do not materialize as expected, cash expenditures and costs that we incur could be materially higher. Moreover, we cannot be certain that regulatory changes will not increase our obligations to provide these or additional benefits. These obligations also may increase substantially in the event of adverse medical cost trends or unexpected rates of early retirement, particularly for bargaining unit retirees for whom there is currently no retiree healthcare cost cap. Early retirement rates likely would increase substantially in the event of a mine closure.

Equipment and supply shortages may impact our production.

The extractive industry has recently experienced long lead times on equipment, tires, and supply needs due to the increased demand for these resources. As the global mining industry increases its capacity, demand for these resources will increase, potentially resulting in higher prices, equipment shortages, or both.

Our sales and competitive position depend on the ability to transport our products to our customers at competitive rates and in a timely manner.

Disruption of the lake freighter and rail transportation services because of weather-related problems, including ice and winter weather conditions on the Great Lakes, strikes, lock-outs or other events, could impair our ability to supply iron ore pellets to our customers at competitive rates or in a timely manner and, thus, could adversely affect our sales and profitability. Further, reduced levels of government funding may result in a lesser level of dredging, particularly at Great Lakes ports. Less dredging results in lower water levels, which restricts the tonnage freighters can haul over the Great Lakes, resulting in higher freight rates.

Our Asia-Pacific Iron Ore operations are in direct competition with the major world seaborne exporters of iron ore and its customers face higher transportation costs than most other Australian producers to ship its products to the Asian markets because of the location of its major shipping port on the south coast of Australia. Further, increases in transportation costs, decreased availability of ocean vessels or changes in such costs relative to transportation costs incurred by our competitors, could make our products less competitive, restrict our access to certain markets and have an adverse effect on our sales, margins and profitability.

Our operating expenses could increase significantly if the price of electrical power, fuel or other energy sources increases.